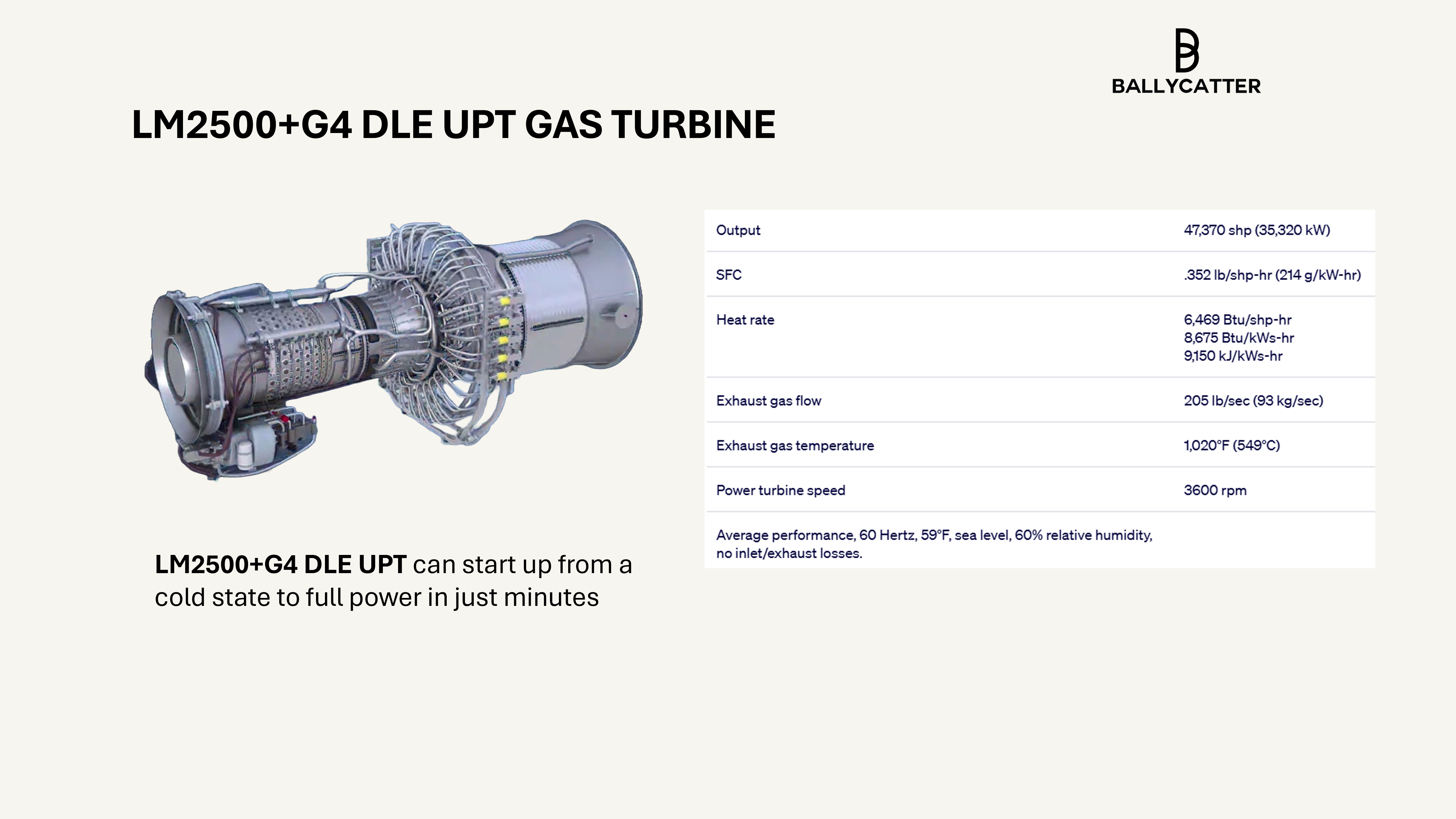

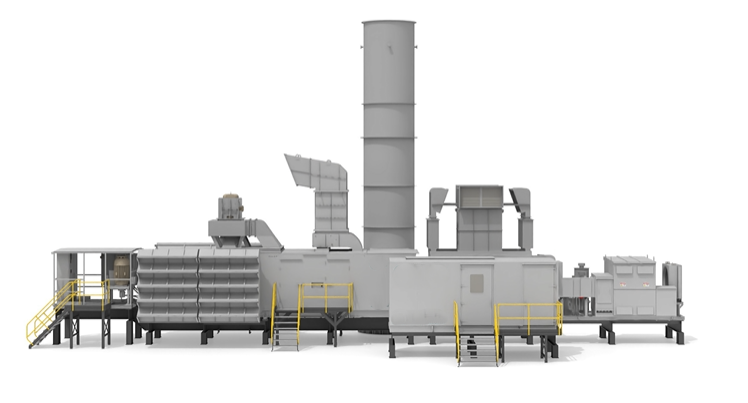

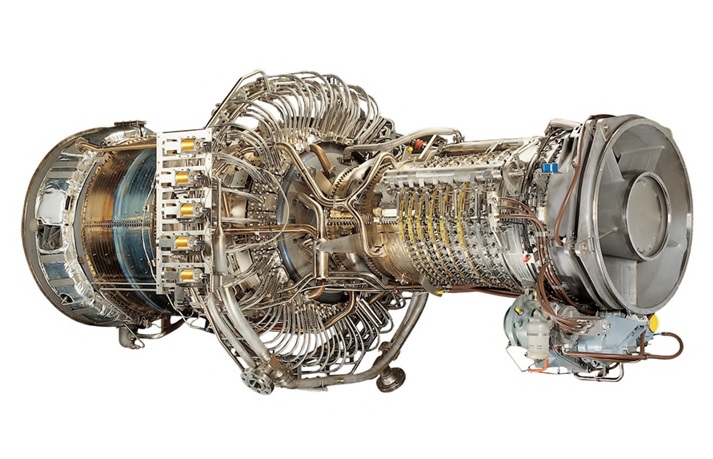

LM2500+G4 DLE U PT Gas Turbine

Gas Turbine

Also known as:

Turbine, Combustion Turbine

LM2500+G4 DLE U PT Gas Turbine

Gas Turbine

Also known as:

Turbine, Combustion TurbineBuy

Made to Order

Product

Price:

Request for QuoteShipping:

Sea freightDelivery Time:

52 WeeksNote:

The LM2500+G4 DLE U PT is ideal for clean mechanical drive applications where higher shaft speeds are needed—featuring Dry Low Emissions and an upgraded power turbine for reliable, high-performance operation.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

The LM2500+G4 DLE U PT features Dry Low Emissions (DLE) technology combined with an upgraded power turbine (U PT). The DLE system lowers nitrogen oxide emissions by controlling combustion temperatures without needing water or steam injection, providing a cleaner and simpler solution. This turbine directly drives equipment such as compressors and pumps in oil and gas operations.

Building on the LM2500+, it features increased airflow and turbine capacity to deliver higher power output. Designed to meet strict environmental standards, the LM2500+G4 DLE U PT offers reliable, efficient, and low-emission performance for demanding mechanical drive applications.

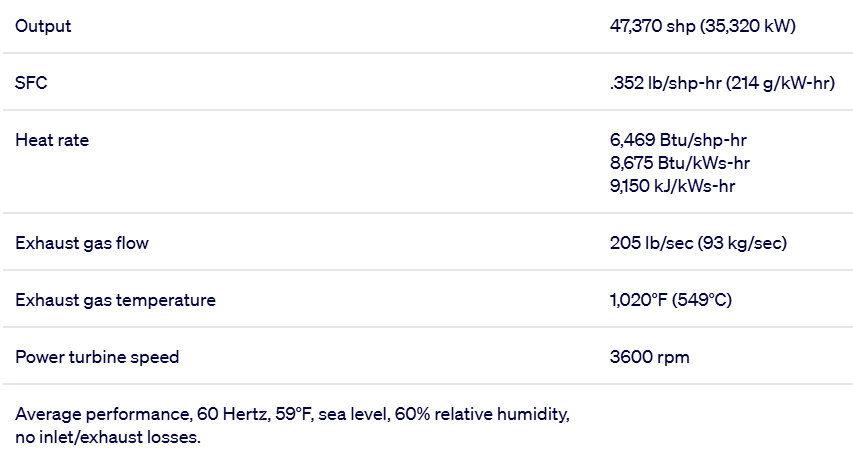

Technical Specifications

| Power | 34.3 MW |

| Output | 47,370 shp (35,320 kW) |

| SFC | .352 lb/shp-hr (214 g/kW-hr) |

| Heat rate | 9407 Btu/shp-hr |

| Exhaust gas flow | 205 lb/sec (93 kg/sec) |

| Exhaust gas temperature | 1,020°F (549°C) |

| Power turbine speed | 3600 rpm |

| High Pressure Compressor | 17-stage; added zero-stage blisk |

| Net efficiency | 36.3% |

Features and Benefits

- More output, high reliability and lower initial capital investment on a $/kW

- For extreme hot and cold ambient condition

- Capable of operating with a variety of fuels

- Lowers nitrogen oxide emissions by controlling combustion temperatures

- Low-emission performance

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

The LM2500+G4 DLE U PT is a versatile gas turbine designed for a wide range of applications, including onshore and offshore power generation, gas pipeline compression, and LNG compression. It features Dry Low Emissions (DLE) technology, which reduces nitrogen oxide (NOx) emissions to as low as 25 parts per million by volume (ppmv) at 15% oxygen, meeting stringent environmental standards.

In the oil and gas industry, production rates are closely linked to available horsepower. The LM2500+G4 DLE U PT offers higher power output, high reliability, and a lower initial cost per kilowatt, making it a cost-effective solution for energy-intensive operations.

This turbine has proven its capability to operate reliably in extreme ambient conditions, with running data demonstrating performance at temperatures as low as -50°F and start-up capability down to -40°F. This wide operational temperature range ensures dependable service in harsh environments.

Fuel flexibility is a key strength of the LM2500+G4 DLE U PT. It can seamlessly switch between various fuels—lean treated natural gas, rich offshore gas, propane, or diesel—without shutting down or losing efficiency. This flexibility supports energy security, allowing continuous operation even if the natural gas supply is interrupted. Additionally, the turbine can be adapted to burn alternative fuels like bioethanol and naphtha, further enhancing fuel options.

A notable advantage of aeroderivative gas turbines like the LM2500+G4 DLE U PT is their ability to operate on hydrogen blends, which produce no carbon emissions when combusted. Both new turbines and existing units can be converted for high hydrogen fuel use, supporting decarbonization goals.

Moreover, the LM2500+G4 DLE U PT is truly dual-fuel capable, able to switch from 100% natural gas to 100% propane without the need for pilot fuels. This contrasts with dual-fuel reciprocating engines, which typically require about 5% diesel during gas operation, increasing costs and emissions. The LM2500+G4 DLE U PT’s fuel flexibility, emission controls, and robust design make it a reliable and efficient choice for demanding mechanical drive and power generation needs in the oil and gas sector.

Engineering Data