Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

Completions

Tubing

Tubing Hanger

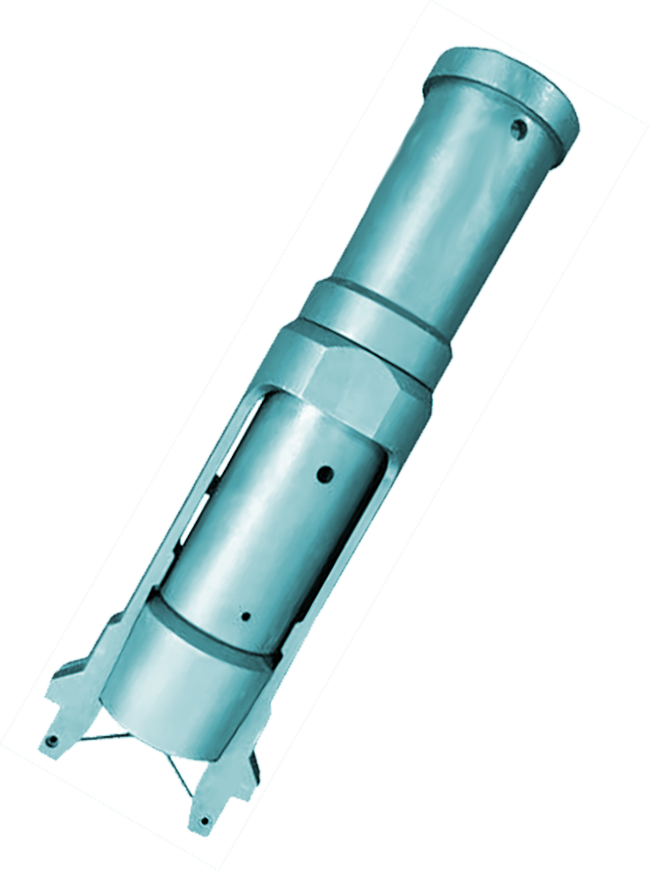

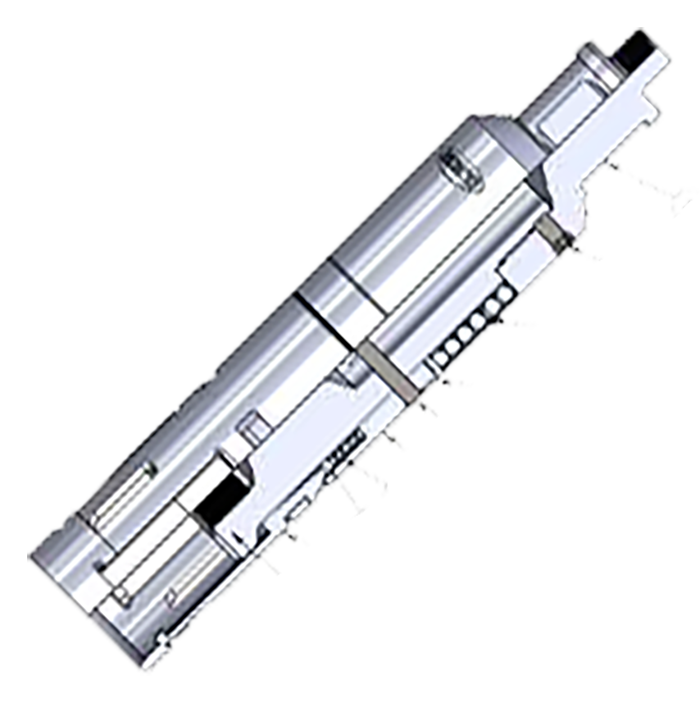

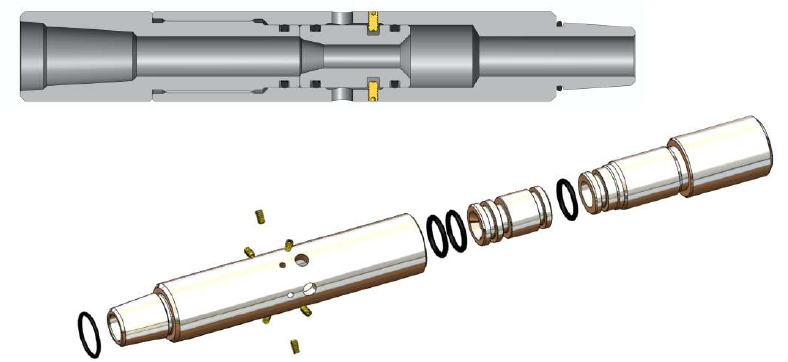

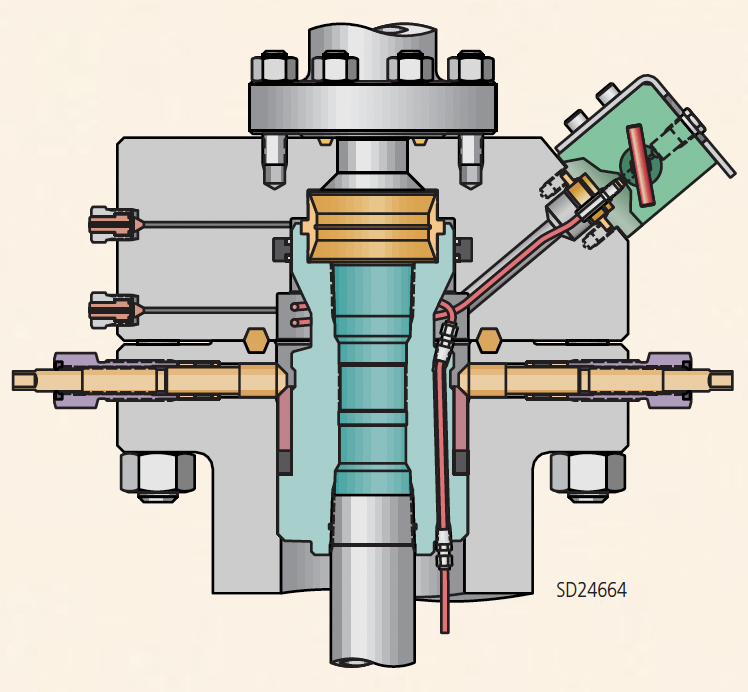

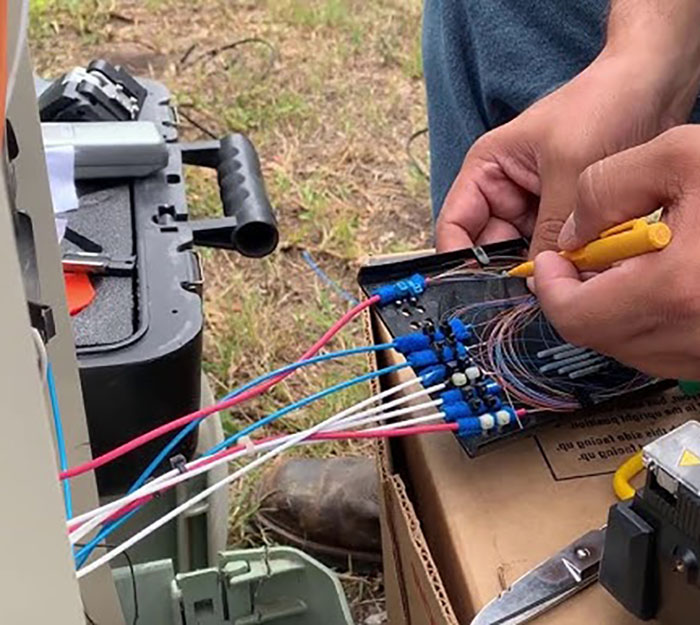

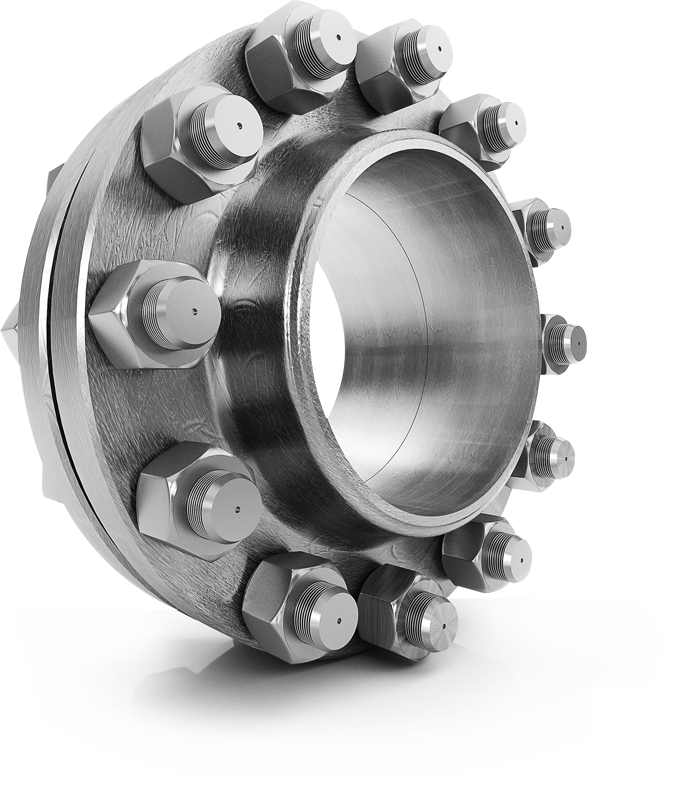

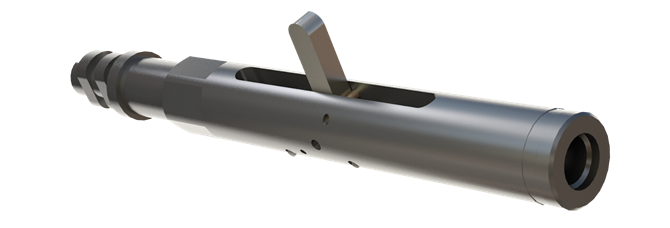

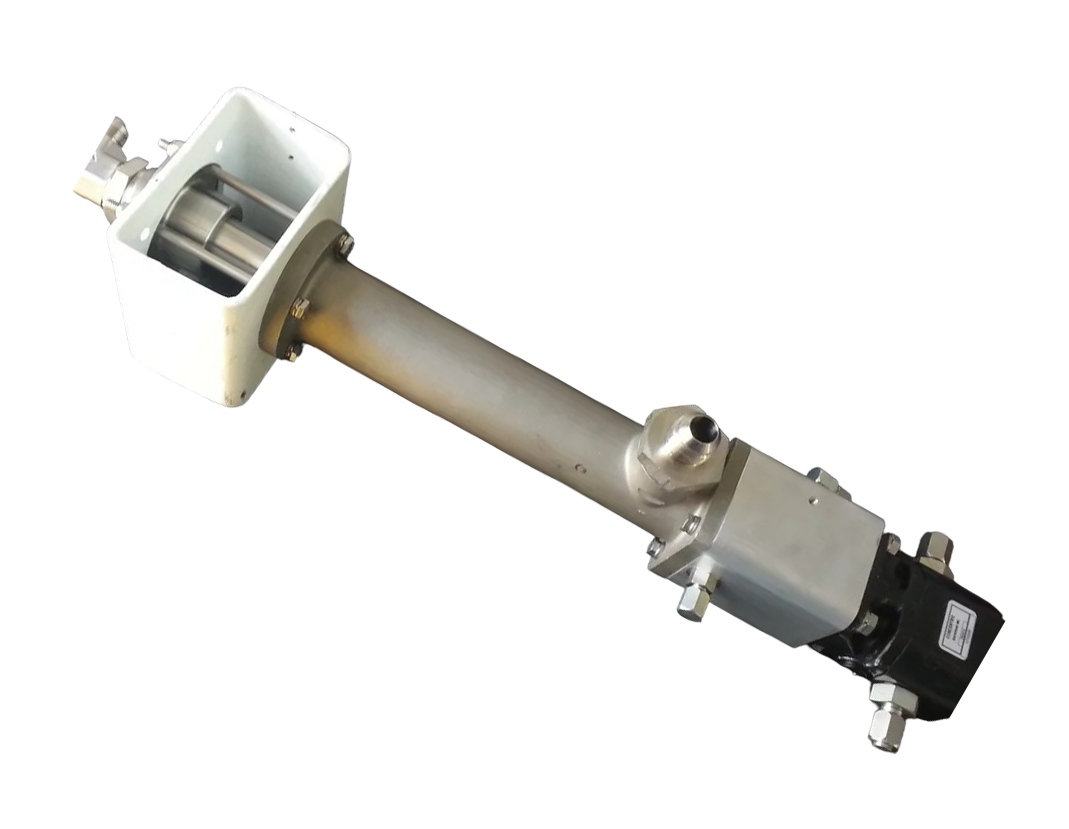

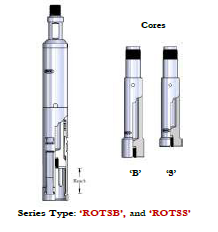

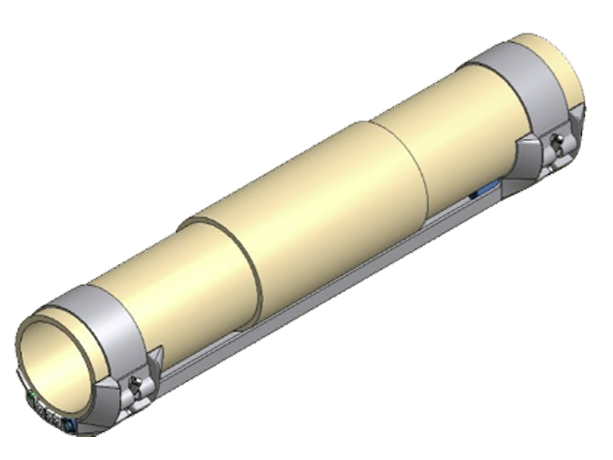

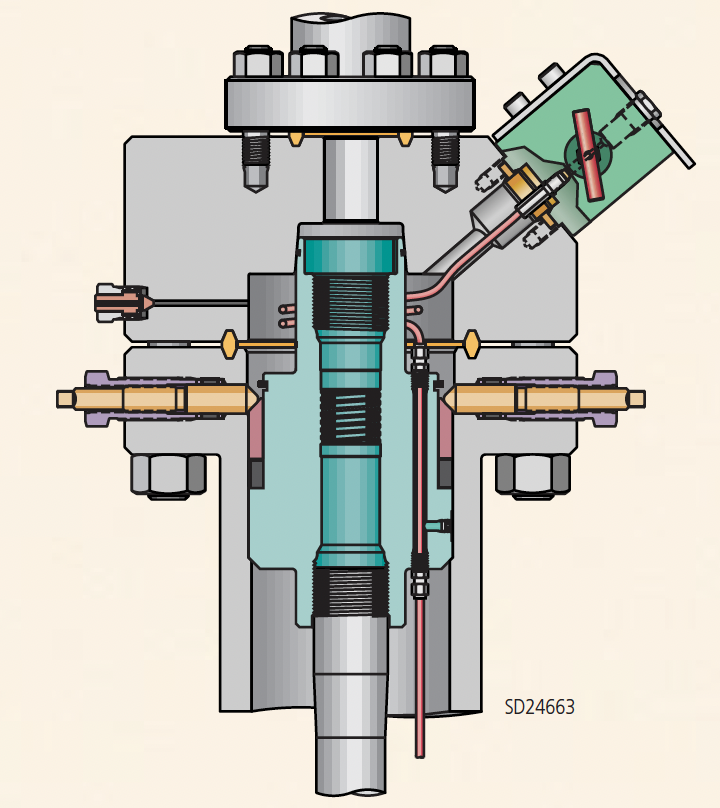

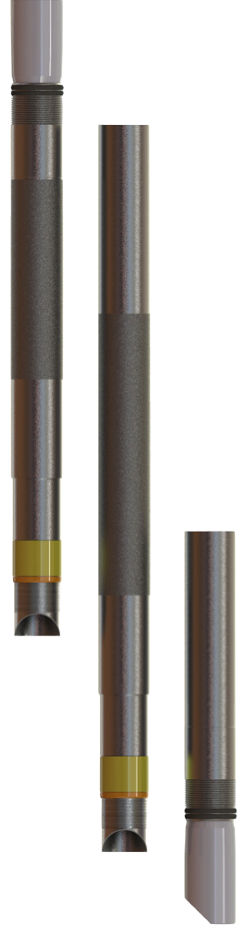

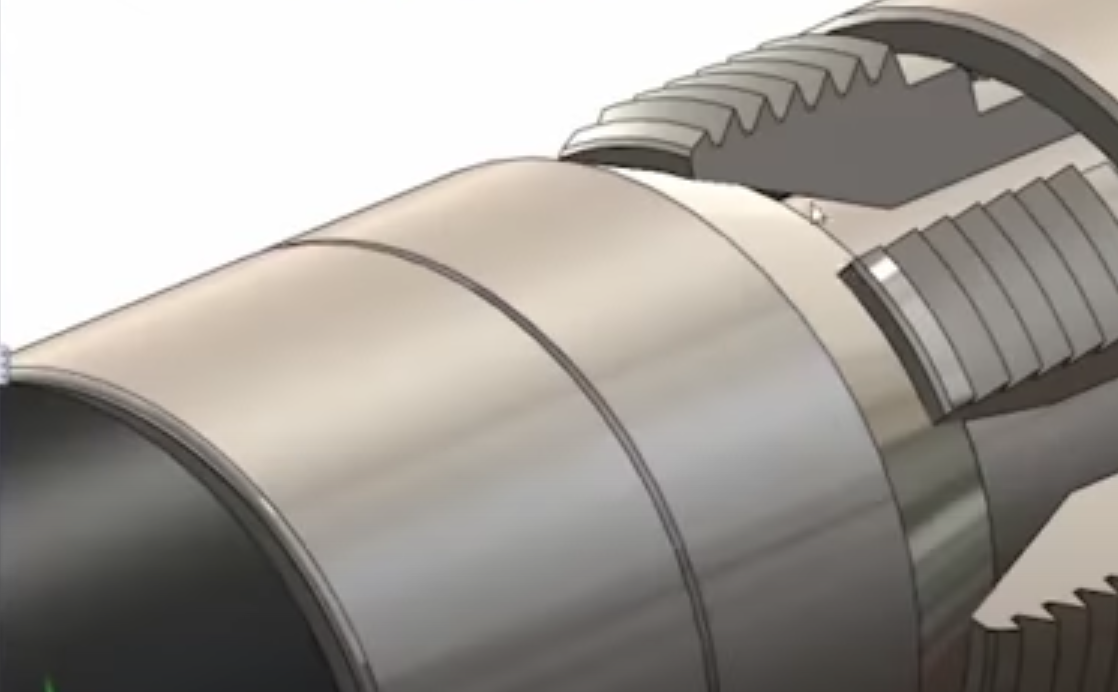

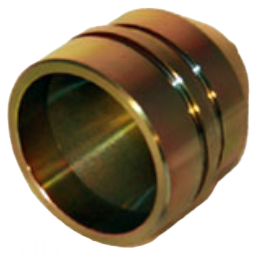

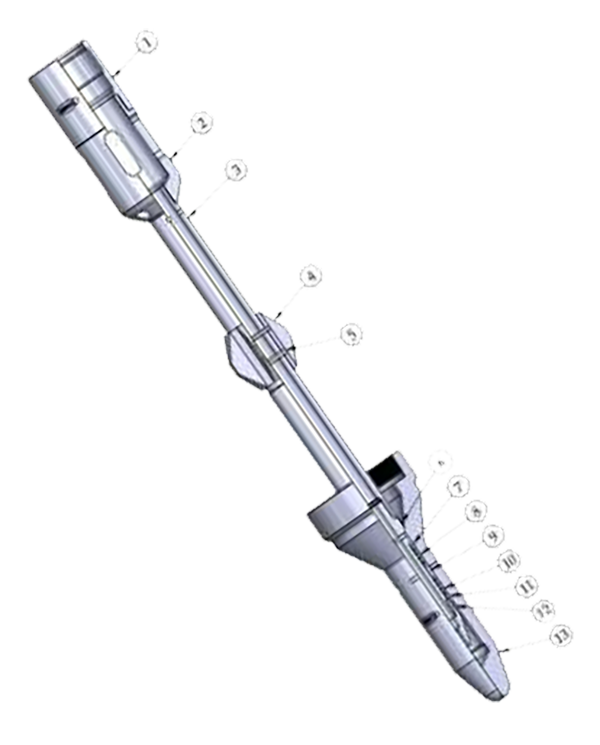

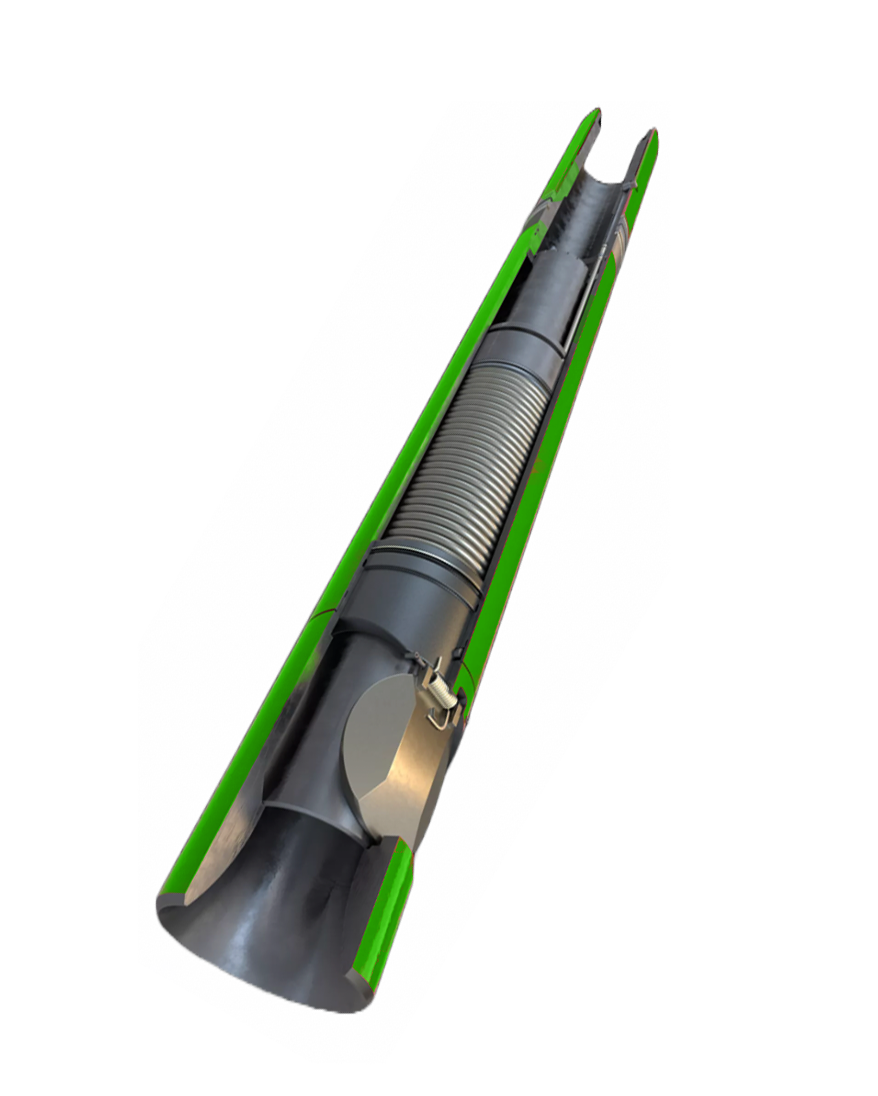

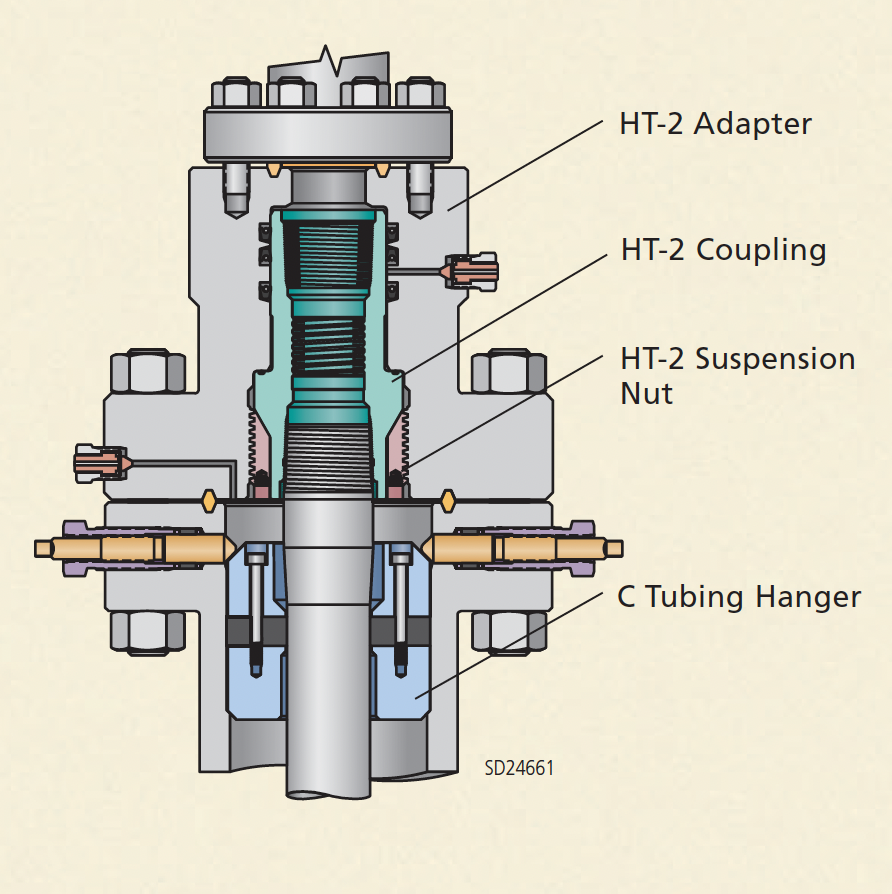

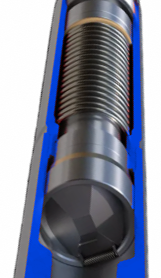

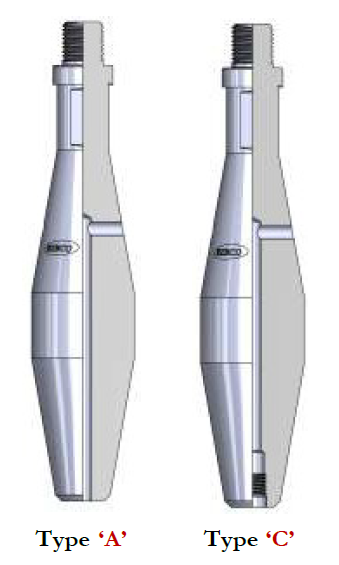

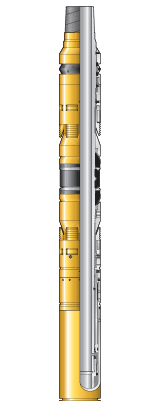

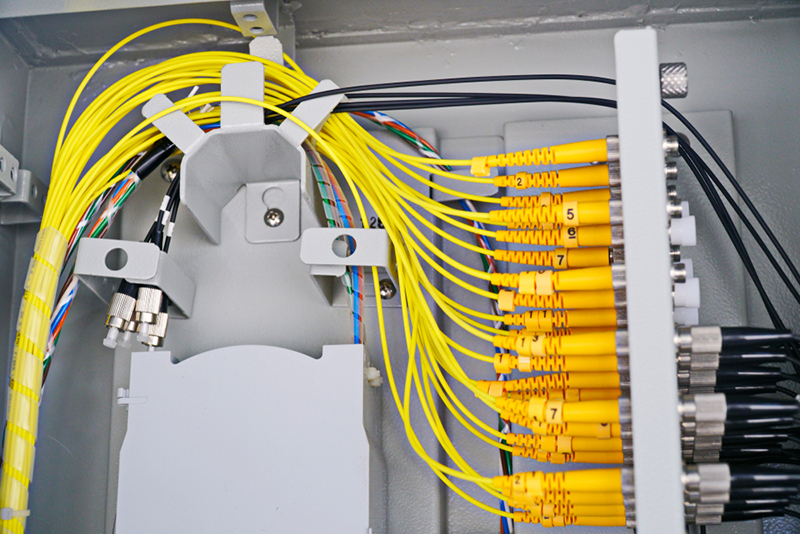

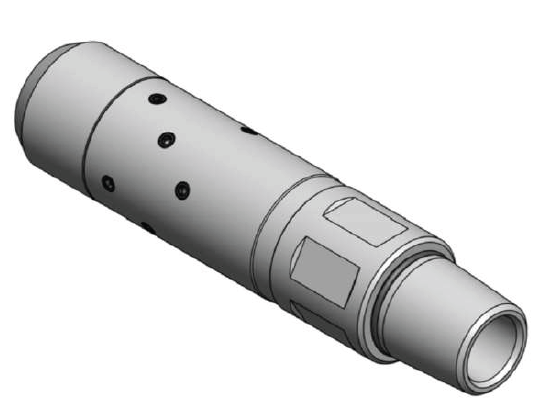

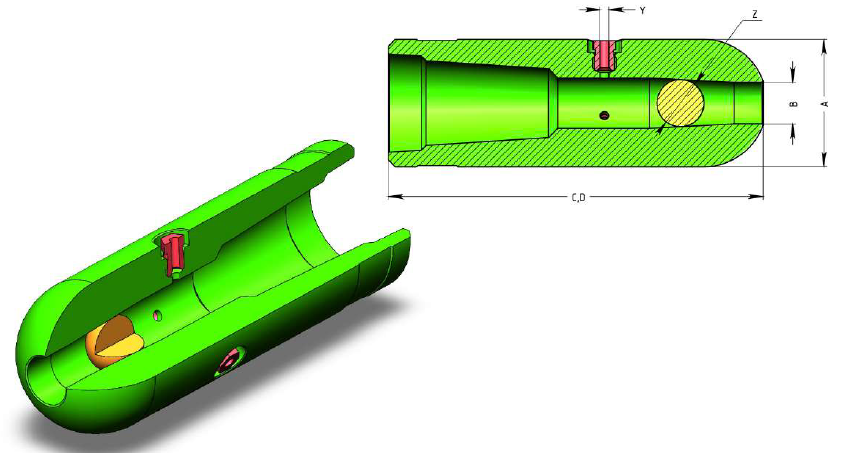

Tubing hangers form part of the primary well barrier while holding the tubing string in place. The tubing hanger is screwed to the top joint of tubing (or pup-joints as required for space out), and is landed in the casing flange (in compression or tension depending on the wellhead assembly) with the elastomeric seals preventing communication between the tubing and A-annulus. Our tubing hangers come in a variety of sizes and specifications for various wellhead manufacturers including Cameron, FMC, Stream-Flo, ABB, Vetco-Gray, and Barbour systems to name a few. We stock inventory from vintage systems, as well as modifying hangers for additional feed-throughs for control lines, electric feed-thru, or downhole fiber-optic as required.

Buy

In Stock

Manufacturer

New

API

Sea Freight

Tubing Hanger

Tubing hangers form part of the primary well barrier while holding the tubing string in place. The tubing hanger is screwed to the top joint of tubing (or pup-joints as required for space out), and is landed in the casing flange (in compression or tension depending on the wellhead assembly) with the elastomeric seals preventing communication between the tubing and A-annulus. Our tubing hangers come in a variety of sizes and specifications for various wellhead manufacturers including Cameron, FMC, Stream-Flo, ABB, Vetco-Gray, and Barbour systems to name a few. We stock inventory from vintage systems, as well as modifying hangers for additional feed-throughs for control lines, electric feed-thru, or downhole fiber-optic as required.

Buy

In Stock

New

Tubing Hanger

Tubing hangers form part of the primary well barrier while holding the tubing string in place. The tubing hanger is screwed to the top joint of tubing (or pup-joints as required for space out), and is landed in the casing flange (in compression or tension depending on the wellhead assembly) with the elastomeric seals preventing communication between the tubing and A-annulus. Our tubing hangers come in a variety of sizes and specifications for various wellhead manufacturers including Cameron, FMC, Stream-Flo, ABB, Vetco-Gray, and Barbour systems to name a few. We stock inventory from vintage systems, as well as modifying hangers for additional feed-throughs for control lines, electric feed-thru, or downhole fiber-optic as required.

Buy

In Stock

New

Tubing Hanger

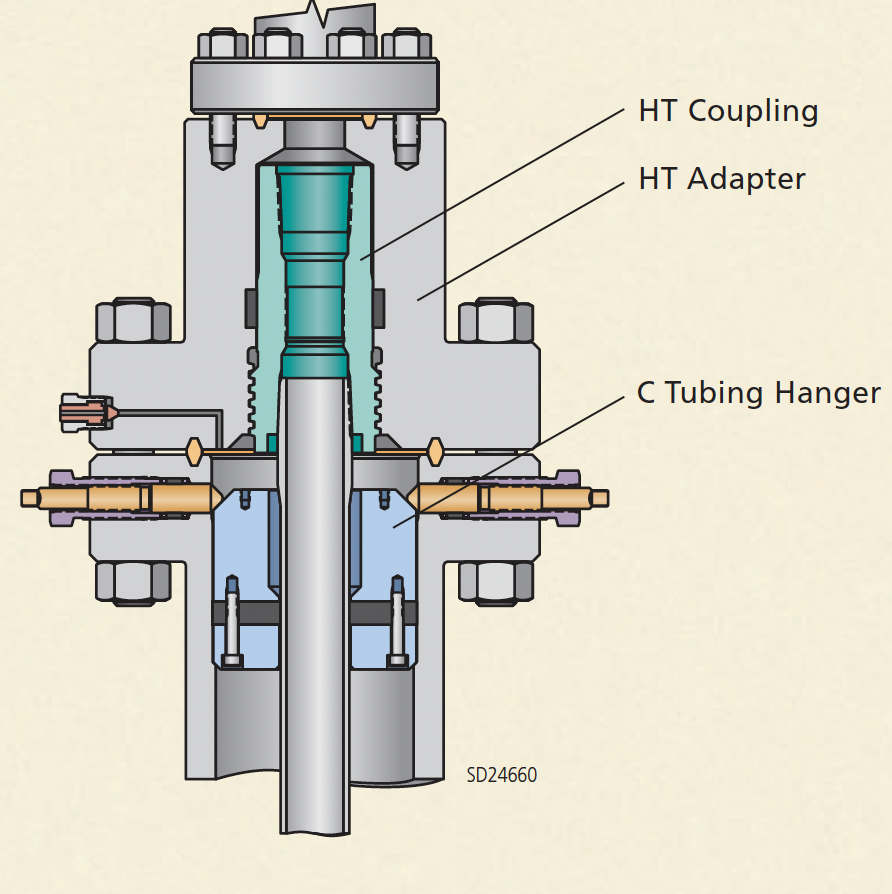

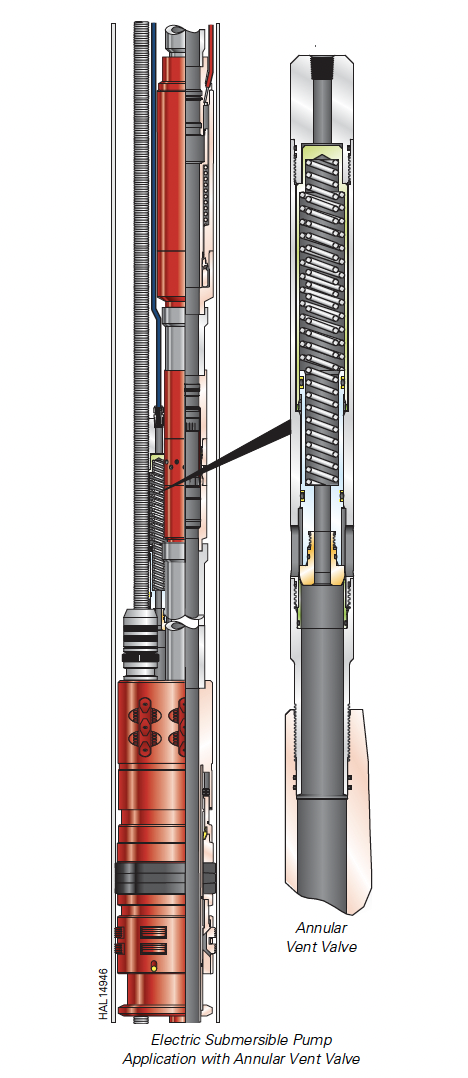

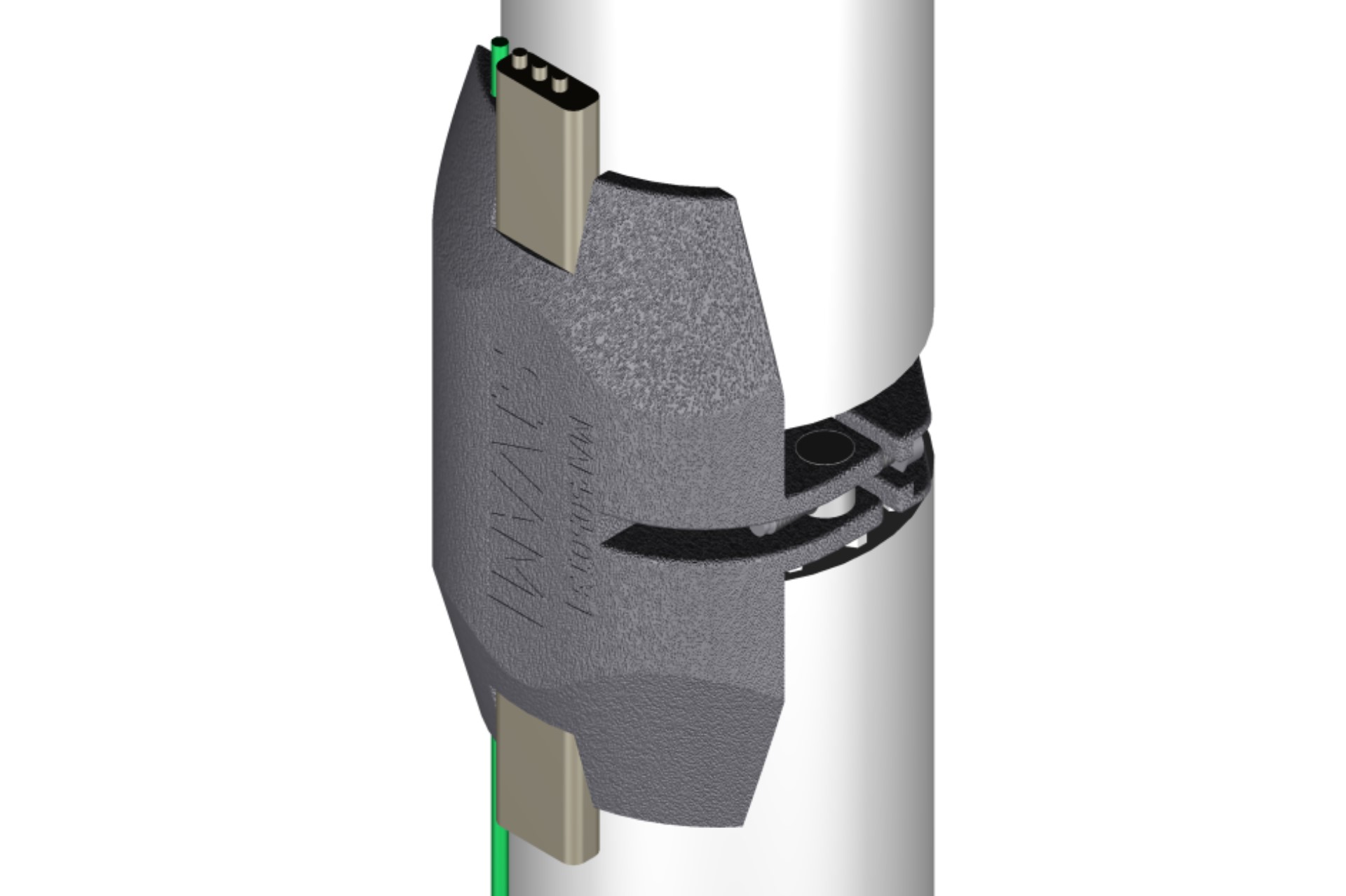

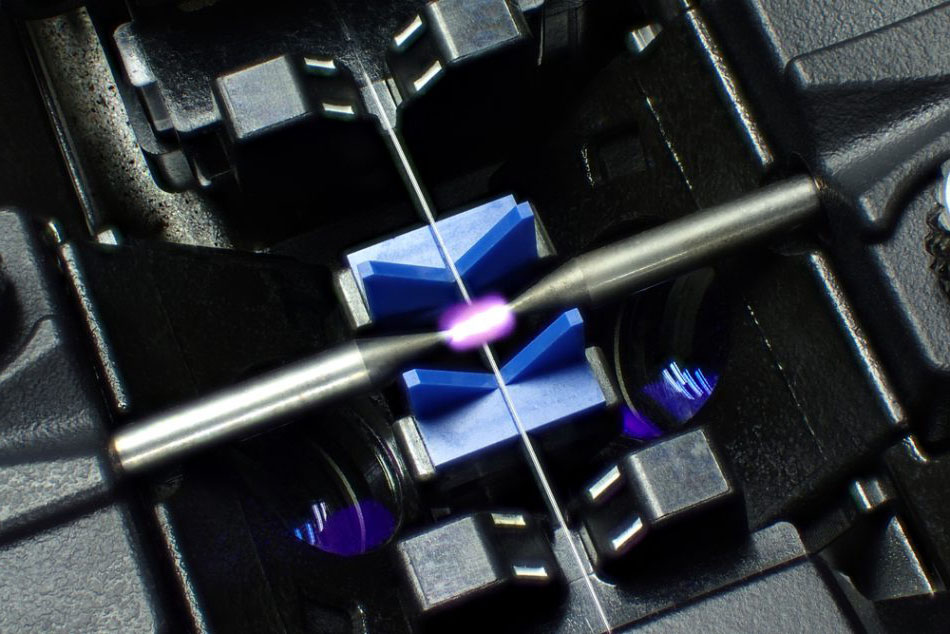

The tubing hanger holds a feed-through mandrel equipped with the proper seals. Feed-through mandrel seals contain well pressure and prevent gas leaks at the surface. Power cables are connected to the two ends of this device via their three-phase connectors (also called: lower and upper pigtails). The feedthru portion of the system provides a fluid block at the wellhead permitting electrical power to pass safely and reliably through the well’s pressure barrier. The connector works with the wellhead manufacturer to assure proper fit and material compatibility.

Buy

In Stock

Product

New

API

Sea Freight

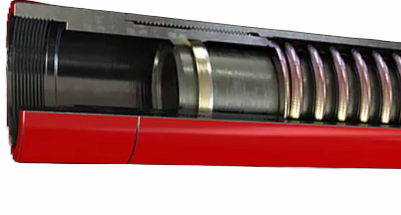

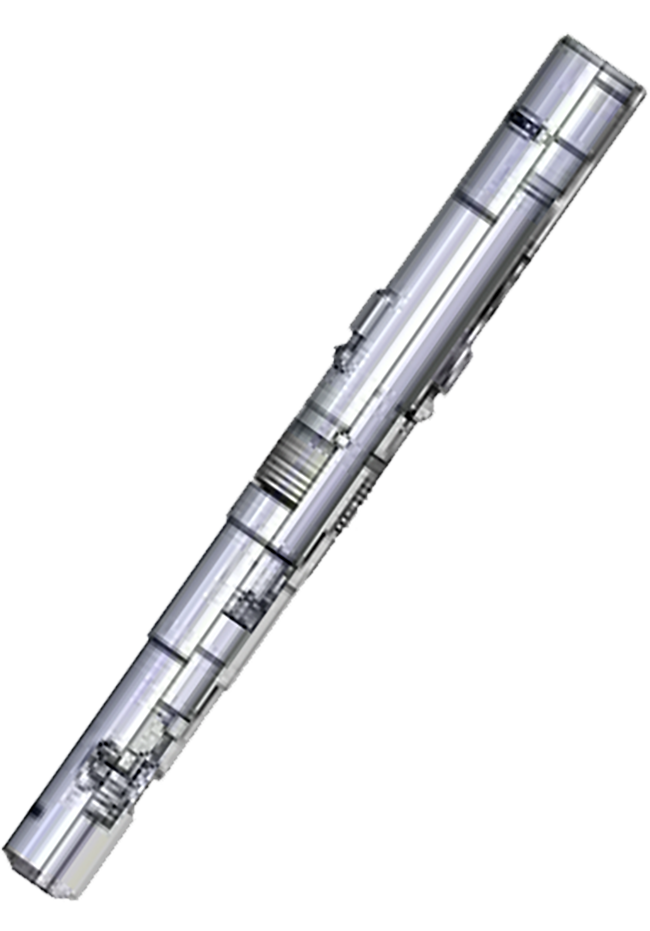

OCTG Tubing

OCTG (Oil Country Tubular Goods) refers to the piping products that are used in oil and gas production and drilling activities. OCTG pipe normally is manufactured based on API specifications. Oil country tubular goods (OCTG) is a family of seamless rolled products consisting of drill pipe, casing and tubing subjected to loading conditions according to their specific application. Tubing is the pipe placed in the well that is exposed to flowing fluids from the reservoir to surface. It is uncemented and able to pulled and replaced in the event the pipe erodes or corrodes. Our international network of manufacturers and warehouses have almost all weights and grades in stock.

Buy

In Stock

Product

New

API

Sea Freight

2 3/8 L80 Tubing

This connection is fully interchangeable with: Wedge 503® - 2.375 in. - 0.19 (4.70) in. (lb/ft) Wedge 533® - 2.375 in. - 0.218 (5.30) / 0.254 (5.95) / 0.295 (6.60) / 0.336 (7.45) in. (lb/ft) Wedge 563® - 2.375 in. - 0.19 (4.60) / 0.218 (5.10) / 0.254 (5.80) / 0.295 (6.60) / 0.336 (7.35) in. (lb/ft)

Buy

In Stock

Product

Used

API

Sea Freight

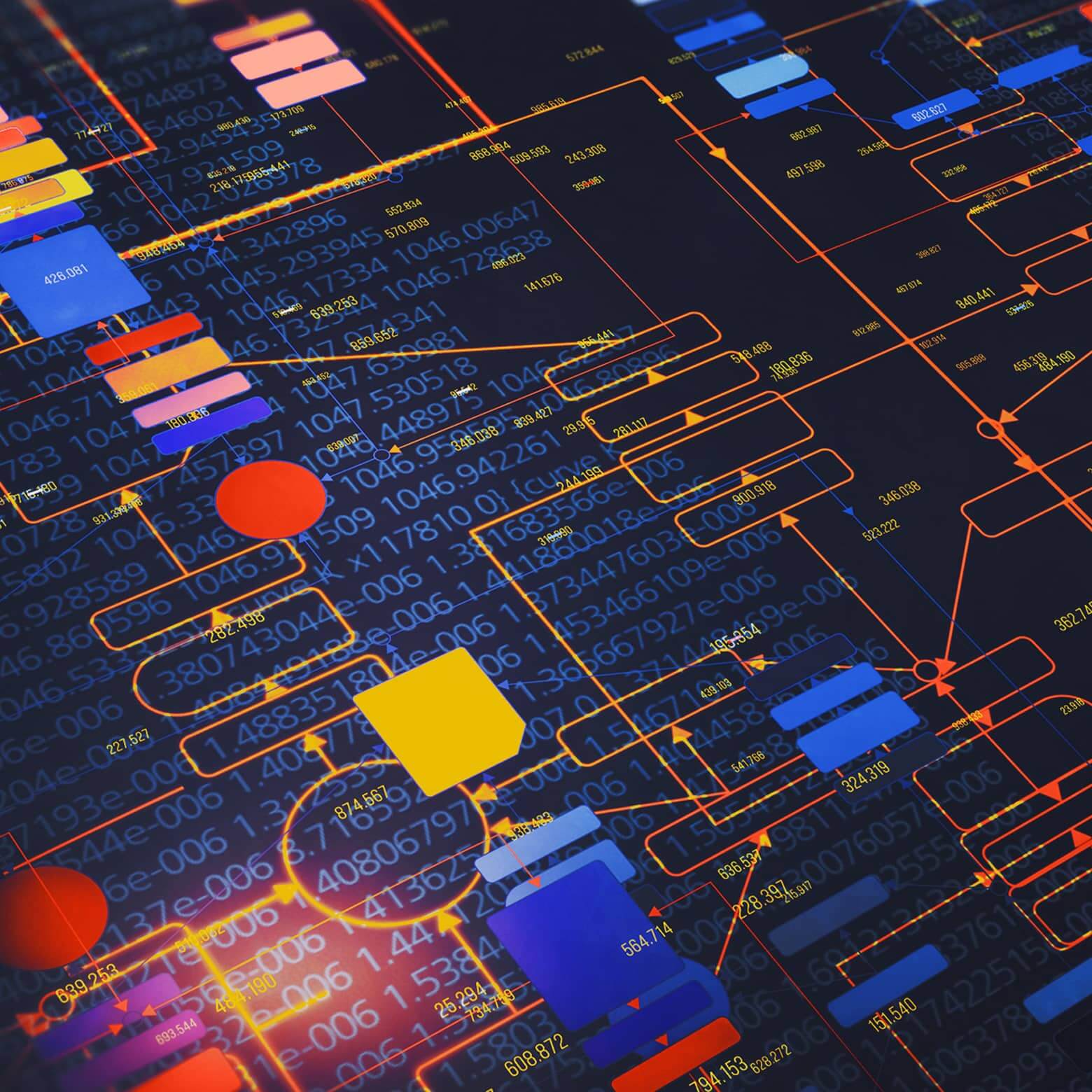

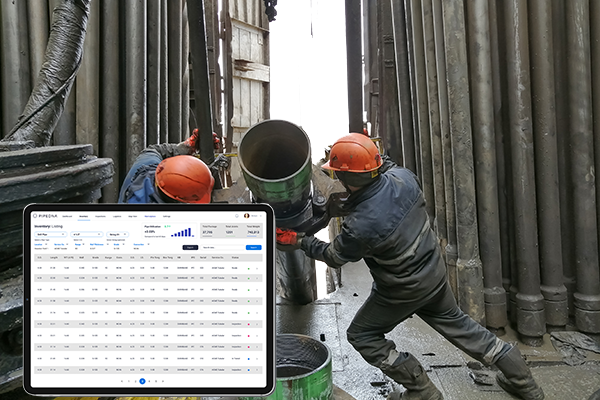

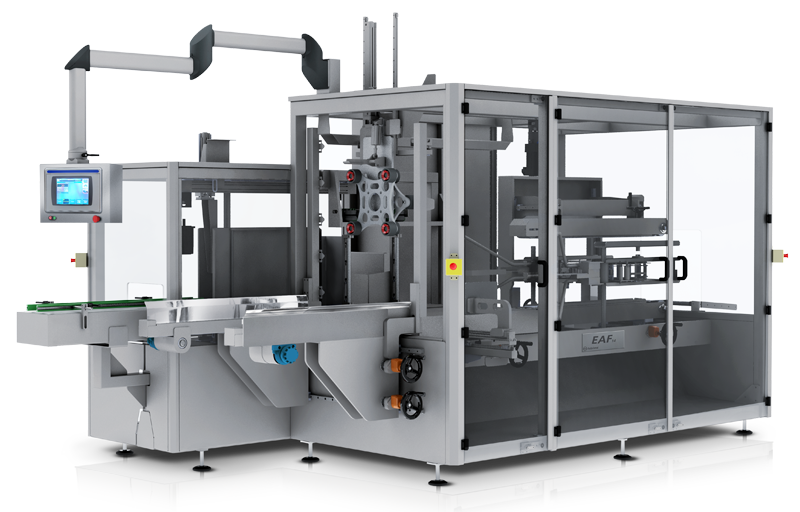

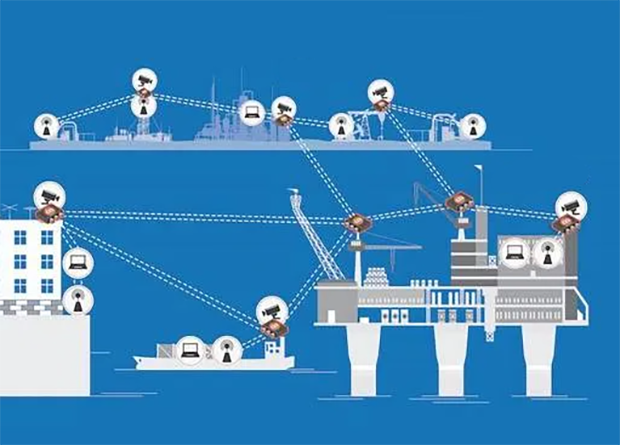

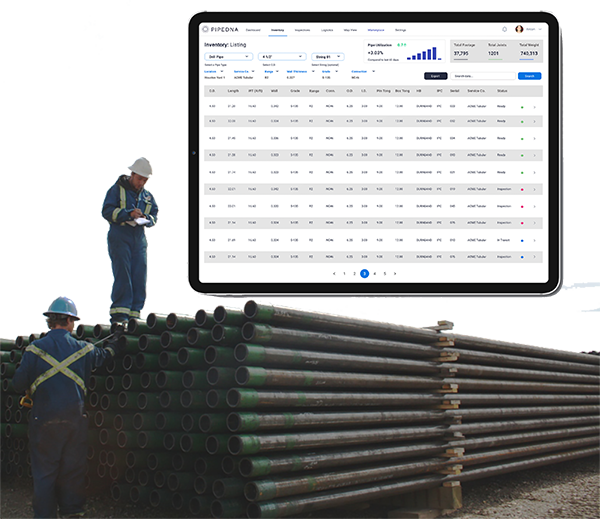

PipeDNA is a cloud-based pipe management solution

Streamlining OCTG Tubular Goods Management with PipeDNA: Boosting Efficiency and Reliability Efficient management of OCTG (Oil Country Tubular Goods) is critical in the oil and gas industry to ensure the success of drilling and production operations. Introducing PipeDNA, a smart cloud-based platform dedicated to managing pipe and tube throughout the oil and gas supply chain. With its powerful features and innovative technology, PipeDNA empowers stakeholders to proactively manage their OCTG tubular goods, increase visibility, and optimize their operations for enhanced efficiency and reliability. Comprehensive Inventory Management and Tracking: PipeDNA offers a comprehensive inventory management and tracking system specifically tailored for OCTG tubular goods. Gain full visibility into your OCTG inventory, including utilization, activity, and trends. By monitoring the status and location of each OCTG pipe, stakeholders can proactively plan for upcoming drilling projects, streamline logistics, and optimize inventory levels. PipeDNA enables accurate tracking, reducing the risk of stockouts, minimizing downtime, and maximizing operational efficiency. Efficient Logistics Management: With PipeDNA, stakeholders can efficiently manage all aspects of logistics operations related to OCTG tubular goods. From shipments to status tracking and documentation, PipeDNA simplifies the entire process, ensuring seamless coordination across multiple locations and parties involved. Furthermore, the platform facilitates pipe bundling, enabling stakeholders to optimize transportation and storage, minimizing costs and improving overall efficiency. Streamlined Inspection Management: PipeDNA's inspection management feature provides a centralized platform to manage inspection jobs for OCTG tubular goods across multiple sites. With real-time tracking and status updates, stakeholders can monitor the progress of inspection jobs, ensuring timely completion and adherence to quality standards. Additionally, the platform enables the management of inspection profiles, allowing for efficient scheduling, tracking, and reporting of inspection activities. Automated Tally Operations: Pipe tallying is a crucial process in OCTG tubular goods management, and PipeDNA simplifies this operation with automated tally operations. Stakeholders can create and manage tally operations within the platform, streamlining the process and eliminating manual calculations. By automating pipe tally jobs and workflows, PipeDNA saves time, reduces errors, and ensures accurate and up-to-date tally results, enhancing overall operational efficiency. Enhanced Identification and Traceability: PipeDNA offers quick and accurate identification of OCTG tubular goods, providing stakeholders with essential pipe details, activity history, and traceability documentation. With seamless integration of popular barcode standards such as UPC, EAN, and QR codes, PipeDNA enables easy identification and tracking of each pipe, ensuring precise inventory control and reducing the risk of misplaced or misused OCTG tubular goods. This enhanced traceability minimizes downtime and improves resource allocation. Designed for the Oil and Gas Industry: PipeDNA was specifically designed for stakeholders across drilling, manufacturing, and oilfield services, catering to their unique needs in OCTG tubular goods management. Whether you are a drilling contractor, oilfield rental company, oilfield and inspection service provider, steel pipe manufacturer, or pipe distribution and storage provider, PipeDNA offers tailored solutions to streamline your OCTG operations and drive efficiency. Leveraging Emerging Technologies: At its core, PipeDNA harnesses the power of today's emerging technologies to optimize OCTG tubular goods management processes. The platform seamlessly integrates with popular barcode standards, such as UPC, EAN, and QR codes, enabling efficient barcoding and labeling. Moreover, PipeDNA is RFID ready, supporting the integration of RFID technologies for accurate asset tracking. The platform also facilitates IoT data integration using the MQTT standard, enabling fast and reliable sensor data integration for enhanced decision-making. PipeDNA revolutionizes OCTG tubular goods management in the oil and gas industry, providing a smart cloud-based platform that enhances efficiency, reliability, and visibility. With its comprehensive inventory management, streamlined logistics operations, automated tallying, and robust identification and traceability features, PipeDNA empowers stakeholders to optimize their OCTG operations and make informed decisions based on real-time data. Leverage the power of PipeDNA and take your OCTG tubular goods management to new heights of efficiency and reliability.

Service

Currently in Use

Service

New

API

Air Freight

PipeDNA is a cloud-based pipe management solution

Enhancing Tubular Manufacturing Traceability with PipeDNA: Ensuring Quality and Compliance In the oil and gas industry, maintaining traceability throughout the tubular manufacturing process is crucial for ensuring quality, compliance, and operational efficiency. Introducing PipeDNA, a smart cloud-based platform dedicated to managing pipe and tube throughout the oil and gas supply chain. With its powerful features and innovative technology, PipeDNA empowers stakeholders to proactively manage tubular manufacturing traceability, increase visibility, and optimize their operations for enhanced quality control. Comprehensive Inventory Management and Tracking: PipeDNA offers comprehensive inventory management and tracking capabilities for tubular products, enabling stakeholders to have full visibility into their manufacturing processes. From raw materials to finished products, PipeDNA allows for seamless tracking of each component, ensuring accurate inventory control, reducing waste, and optimizing production planning. Gain insights into utilization, activity, and trends, empowering stakeholders to make data-driven decisions and streamline their manufacturing operations. Streamlined Logistics Management: PipeDNA simplifies logistics management by providing stakeholders with a centralized platform to manage shipments, track status, and document crucial information. Whether it's inbound or outbound logistics, PipeDNA ensures seamless coordination and real-time visibility into the movement of tubular products. The platform also facilitates pipe bundling, allowing stakeholders to optimize transportation and storage, reducing costs and improving overall efficiency. Efficient Inspection Management: With PipeDNA's inspection management feature, stakeholders can effectively manage inspection jobs throughout the tubular manufacturing process. From initial inspections of raw materials to final product inspections, PipeDNA enables tracking and monitoring of job status across multiple sites. By streamlining inspection profiles and documentation, stakeholders can ensure compliance with quality standards, reduce errors, and maintain consistent product quality. Automated Tally Operations: PipeDNA simplifies and automates the tallying process during tubular manufacturing. Stakeholders can create and manage tally operations within the platform, eliminating manual calculations and reducing the risk of errors. By automating pipe tally jobs and workflows, PipeDNA saves time, improves accuracy, and enhances overall manufacturing efficiency. Accurate tally operations enable stakeholders to maintain reliable records and ensure traceability throughout the production cycle. Enhanced Identification and Traceability: PipeDNA's identification and traceability features provide stakeholders with quick and accurate pipe identification, detailed pipe information, activity history, and traceability documentation. By integrating popular barcode standards such as UPC, EAN, and QR codes, PipeDNA enables seamless identification and tracking of each tubular product. This enhanced traceability minimizes the risk of errors, supports efficient recalls if necessary, and ensures compliance with industry regulations. Designed for the Oil and Gas Industry: PipeDNA was designed specifically for stakeholders across drilling, manufacturing, and oilfield services, catering to their unique needs in tubular manufacturing traceability. Whether you are a drilling contractor, oilfield rental company, oilfield and inspection service provider, steel pipe manufacturer, or pipe distribution and storage provider, PipeDNA offers tailored solutions to streamline your tubular manufacturing processes and drive quality and compliance. Leveraging Emerging Technologies: At its core, PipeDNA leverages today's emerging technologies to optimize tubular manufacturing traceability. The platform integrates popular barcode standards such as UPC, EAN, and QR codes, allowing for efficient barcoding and labeling. Furthermore, PipeDNA is RFID ready, supporting the integration of RFID technologies for accurate asset tracking and improved traceability. The platform also enables IoT data integration using the MQTT standard, facilitating fast and reliable sensor data integration for enhanced decision-making during the manufacturing process. PipeDNA revolutionizes tubular manufacturing traceability in the oil and gas industry, providing a smart cloud-based platform that enhances quality control, compliance, and visibility. With its comprehensive inventory management, streamlined logistics operations, efficient inspection management, automated tally operations, and enhanced identification and traceability features, PipeDNA empowers stakeholders to optimize their tubular manufacturing processes, minimize errors, and ensure compliance with industry standards. Leverage the power of PipeDNA and take your tubular manufacturing traceability to new heights of efficiency and reliability.

Service

Currently in Use

Service

New

API

Air Freight

PipeDNA is a cloud-based pipe management solution

Enhancing Tubular Inspection Management with PipeDNA: Streamlining Quality Assurance in the Oil and Gas Industry In the oil and gas industry, ensuring the quality and integrity of tubular products is of paramount importance. Introducing PipeDNA, a smart cloud-based platform dedicated to managing pipe and tube throughout the oil and gas supply chain. With its powerful features and innovative technology, PipeDNA empowers stakeholders to effectively manage and streamline tubular inspection processes, enabling enhanced quality assurance and compliance. Efficient Management of Inspection Jobs: PipeDNA provides a comprehensive solution for managing inspection jobs across multiple sites. Stakeholders can easily create and track inspection jobs, monitor their status, and manage inspection profiles within the platform. This streamlined approach eliminates manual and time-consuming processes, ensuring efficient coordination and effective allocation of inspection resources. Real-time Job Status and Reporting: With PipeDNA, stakeholders can access real-time updates on the status of inspection jobs. The platform enables instant communication and collaboration between inspectors, supervisors, and other relevant parties involved in the inspection process. By providing a centralized hub for reporting and documentation, PipeDNA enhances transparency and allows for swift decision-making based on accurate and up-to-date information. Tailored Inspection Profiles: PipeDNA allows stakeholders to create and manage inspection profiles specific to their tubular products. Customizable inspection profiles enable stakeholders to define the required tests, measurements, and criteria for each type of tubular product. By tailoring inspection profiles to their unique needs, stakeholders can ensure adherence to industry standards and regulatory requirements, ultimately guaranteeing the quality and safety of their tubular assets. Seamless Integration of Inspection Data: PipeDNA offers seamless integration of inspection data, eliminating the need for manual data entry and reducing the risk of human errors. The platform allows for the integration of manufacturing data, ensuring that inspection results are directly linked to the production process. By automating the transfer of data, PipeDNA enables stakeholders to maintain accurate and reliable records, enhancing traceability and facilitating data-driven decision-making. Enhanced Identification and Traceability: PipeDNA's identification and traceability features provide stakeholders with quick and accurate pipe identification, detailed pipe information, activity history, and traceability documentation. By integrating popular barcode standards such as UPC, EAN, and QR codes, PipeDNA enables seamless identification and tracking of each tubular product. This enhanced traceability minimizes the risk of errors, supports efficient recalls if necessary, and ensures compliance with industry regulations. Leveraging Emerging Technologies: PipeDNA leverages today's emerging technologies to optimize tubular inspection management. The platform supports barcoding and labeling systems, integrating popular barcode standards for efficient identification and tracking. PipeDNA is RFID ready, allowing for integration with RFID technologies such as labels and asset tags, further enhancing asset tracking and traceability. Additionally, PipeDNA supports IoT data integrations using the MQTT standard, enabling fast and reliable sensor data integration for enhanced inspection processes. PipeDNA revolutionizes tubular inspection management in the oil and gas industry, providing a smart cloud-based platform that streamlines quality assurance processes. By offering efficient management of inspection jobs, real-time status updates, tailored inspection profiles, seamless data integration, and enhanced identification and traceability, PipeDNA empowers stakeholders to ensure the highest level of quality and compliance in their tubular assets. Embrace PipeDNA and elevate your tubular inspection management to new levels of efficiency and reliability.

Service

Currently in Use

Service

New

API

Air Freight

Software Development

ELEKS: Empowering Risk Management for a Secure Energy Future Navigate the complexities of the energy and utility sector with confidence, backed by ELEKS' custom software engineering expertise. Our specialized team can guide you in developing and implementing cutting-edge software solutions for power network monitoring and analysis, enabling you to effectively manage risks, address weaknesses, and predict potential challenges. Elevate Your Risk Management with ELEKS Energy Software Development: Embrace the power of advanced energy management software solutions that redefine the productivity, accessibility, safety, and sustainability of your business power system. Comprehensive Risk Assessment: With our software solutions, identify your power system's weak points swiftly and accurately. Effectively address network issues and predict potential risks, enabling you to take timely preventive measures. Custom Solutions Tailored to You: Collaborate with ELEKS to develop custom energy management software solutions designed to cater precisely to your risk management needs. Gain insights that empower you to make informed decisions. Why Choose ELEKS? Industry Expertise: ELEKS boasts a team of specialists with comprehensive experience in custom software engineering for the energy and utility sector. Trust us to understand and address your unique challenges. Predictive Insights: Stay ahead of potential risks with predictive analysis powered by our software solutions. Leverage insights to take preventive measures and ensure the stability of your power network. Cutting-Edge Technologies: Our solutions harness the latest technologies, including Cloud, IoT, blockchain, and more. Future-proof your risk management strategies with innovation at your fingertips. Empower a Secure Energy Future: In a dynamic industry where risks abound, ELEKS empowers you to manage uncertainties effectively. Secure your energy future with a proactive approach to risk assessment and mitigation. Join the Energy Resilience Revolution with ELEKS Embrace a future where risks are managed proactively and uncertainties are addressed with precision. ELEKS' energy software development solutions equip you with the tools needed to navigate the energy and utility sector confidently. It's time to lead the way towards a secure energy future – choose ELEKS as your partner in risk management and innovation.

Service

Made to Order

Product

New

ISO

Digital

Software Development

Transforming Efficiency: Elevate Your Operations with ELEKS Experience a new level of operational efficiency with ELEKS' custom software development and data science services. Our cutting-edge solutions empower utility companies to embrace intelligent automation, optimizing complex processes and workflows across logistics, inventory management, warehousing, production planning, billing, and consumer management. With ELEKS as your partner, you can streamline your operations, achieve peak efficiency, and realize substantial cost savings. Empower Your Operations with ELEKS Energy Software Development: Embrace an advanced energy management software solution that revolutionizes productivity, accessibility, safety, and sustainability within your business power system. Intelligent Automation Expertise: Our custom software development and data science services enable you to adopt intelligent automation for critical processes. Say goodbye to repetitive, labor-intensive tasks and hello to efficiency and accuracy. Real-Time Insights: Gain real-time data on your operational conditions. Our solutions provide you with up-to-the-minute insights that help you make informed decisions and stay ahead of challenges. Minimize Errors and Costs: Automation minimizes human errors, reducing the risk of costly mistakes in critical processes. Achieve cost savings by optimizing workflows and minimizing resource wastage. Why Choose ELEKS? Proven Excellence: ELEKS boasts a 30-year legacy of excellence in custom software development. Our solutions are tried, tested, and trusted by energy producers, distributors, and governmental organizations. Cutting-Edge Innovation: Stay ahead of the curve with our utilization of cutting-edge technologies, including Cloud, IoT, blockchain, and data-driven solutions. Our software development team is equipped to address the evolving needs of the energy and utility industry. Tailored to Your Needs: Our solutions are tailored to your specific requirements, ensuring that you receive a technology platform that seamlessly integrates into your existing workflows. Revolutionize Your Operations: Join the ranks of industry leaders who are revolutionizing their operations through intelligent automation. With ELEKS as your partner, you can optimize processes, enhance accuracy, and unlock significant cost savings. Lead the Change with ELEKS ELEKS' custom software development and data science services empower utility companies to take charge of their operations, embracing automation for lasting efficiency gains. Say goodbye to manual, error-prone processes and hello to streamlined workflows and real-time insights. Take your operations to the next level – choose ELEKS as your partner in transformation.

Service

Made to Order

Service

New

ISO

Digital

SMAW Welder

Unleash the Power of Versatility with the Stickwelder 162 D! At Canaweld, we understand the diverse welding needs of the construction, oil & gas industries, and more. That's why we are thrilled to introduce the Stickwelder 162 D - a welding marvel that offers high-quality performance across a wide range of metals and thicknesses, ensuring impeccable results in every project. Portable Powerhouse The Stickwelder 162 D is designed to be your reliable companion, offering portability, power, and versatility in one compact unit. Whether you require Stick Welding or TIG welding with a lift start, this welding machine rises to the occasion, delivering consistent and exceptional welds. Safety and Efficiency Combined We understand the challenges of adverse conditions, which is why we've equipped the Stickwelder 162 D with an extra function that reduces power draw, ensuring safer and more efficient performance in challenging environments. When precision matters, trust the Stickwelder 162 D to get the job done. Ideal for Light to Medium Duty Projects From construction sites to oil & gas projects, the Stickwelder 162 D is the ideal choice for light to medium-duty projects, providing reliability and flexibility in all weather conditions. Its lightweight construction and convenient carrying belt make transportation a breeze, ensuring you can take this welding powerhouse wherever the job demands. Weld with Confidence Enjoy excellent arc characteristics with the most common rods up to 5/32 inches, providing you with the confidence to tackle a variety of welding tasks. Experience low power consumption, making it energy-efficient and eco-friendly. Ready for the Outdoors The Stickwelder 162 D is designed to work outdoors with the appropriate power generator, offering you the freedom to take on welding projects wherever they may be. It's fan-cooled and thermally protected, ensuring durability and performance even in demanding conditions. The Canaweld Promise With Canaweld's Stickwelder 162 D, you can rely on the Canaweld promise of excellence and durability. Our comprehensive 3-year warranty further solidifies our commitment to quality and customer satisfaction. Get the job done right with the Stickwelder 162 D. Embrace the power of versatility, portability, and efficiency, and elevate your welding experience with Canaweld. Whether you're on a construction site or in the oil & gas industry, trust the Stickwelder 162 D to deliver flawless welds. Choose the welding machine designed with your needs in mind - the Stickwelder 162 D. Welding Perfected!

Buy

In Stock

Manufacturer

New

ASME

Land Freight

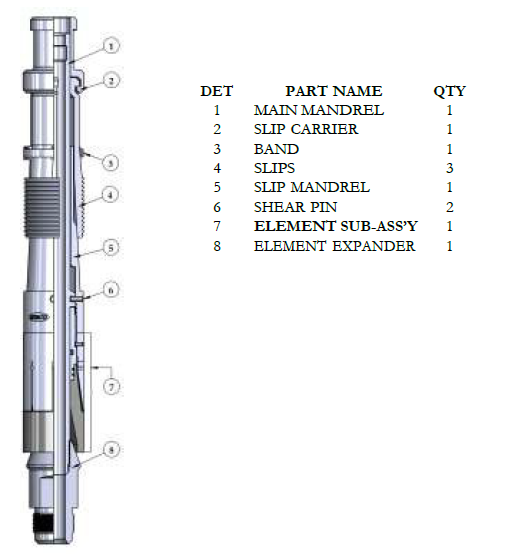

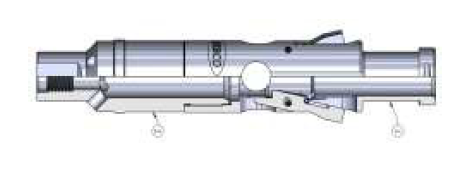

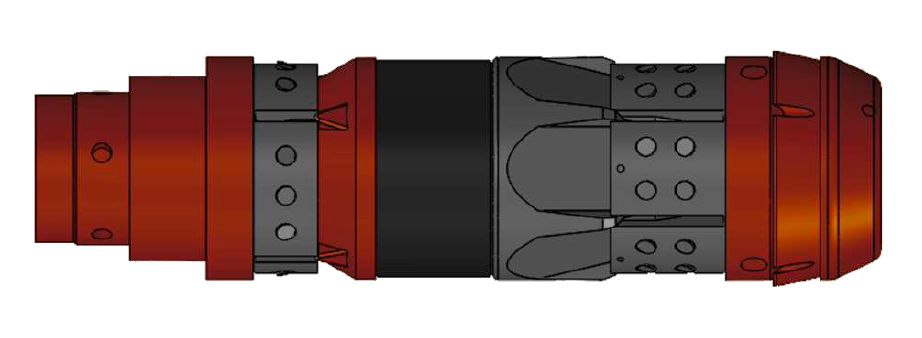

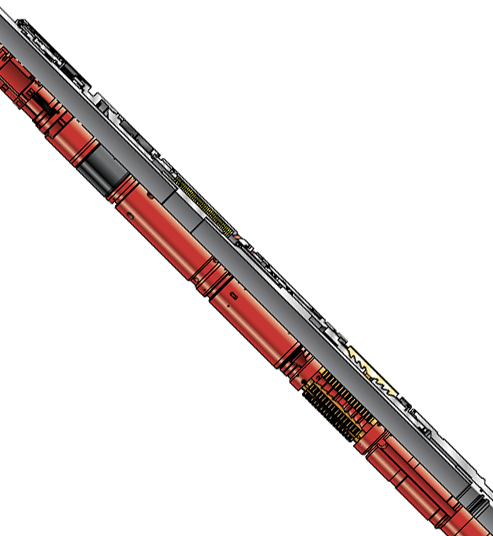

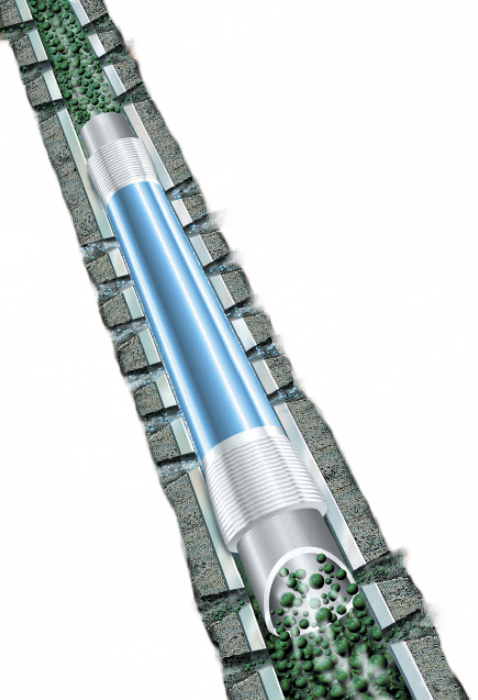

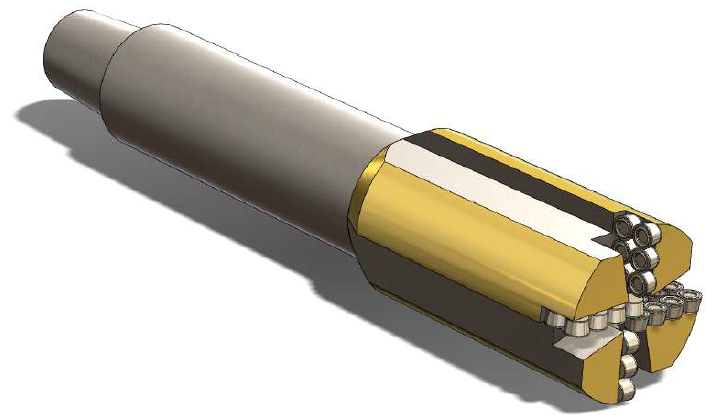

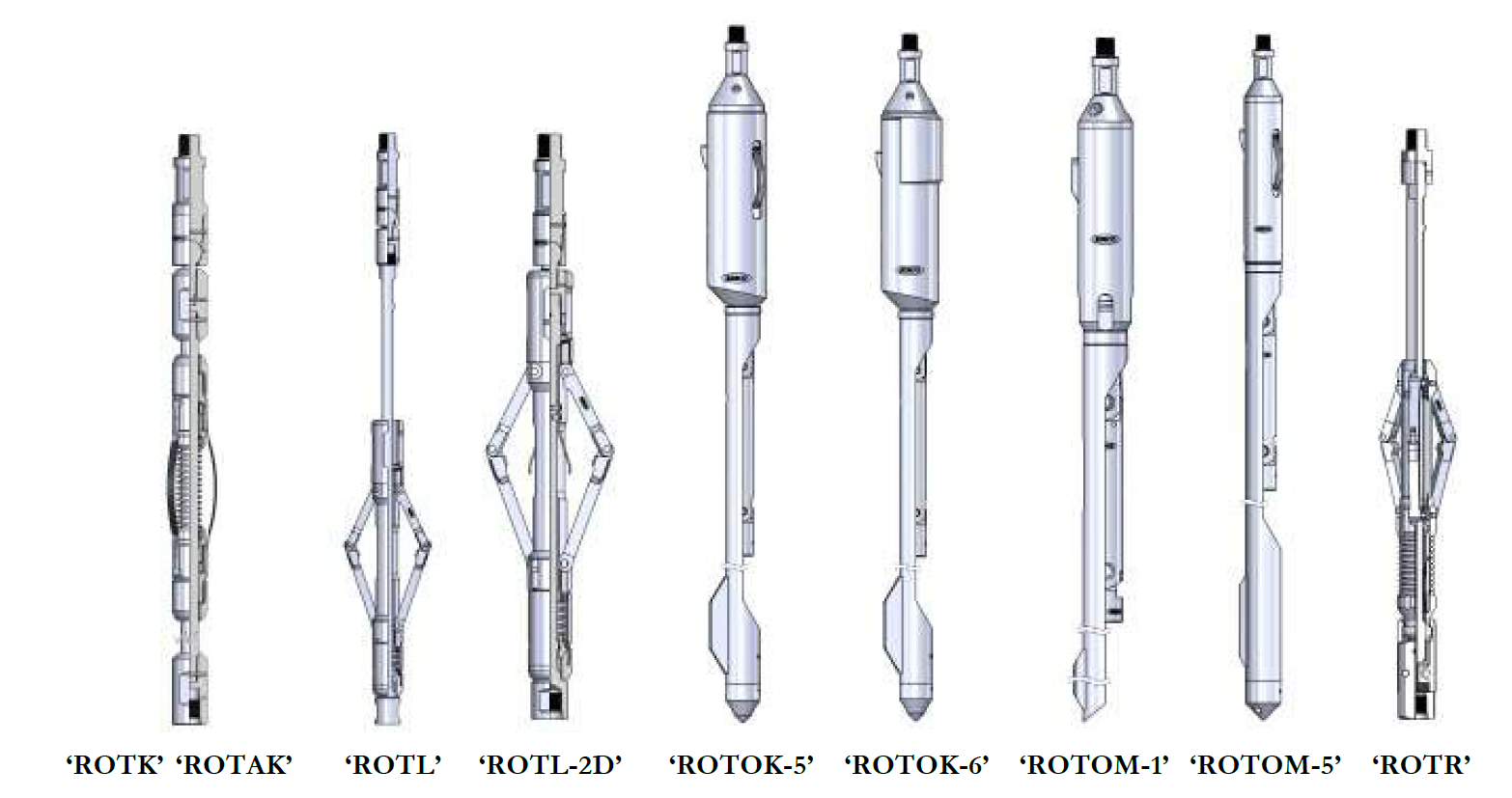

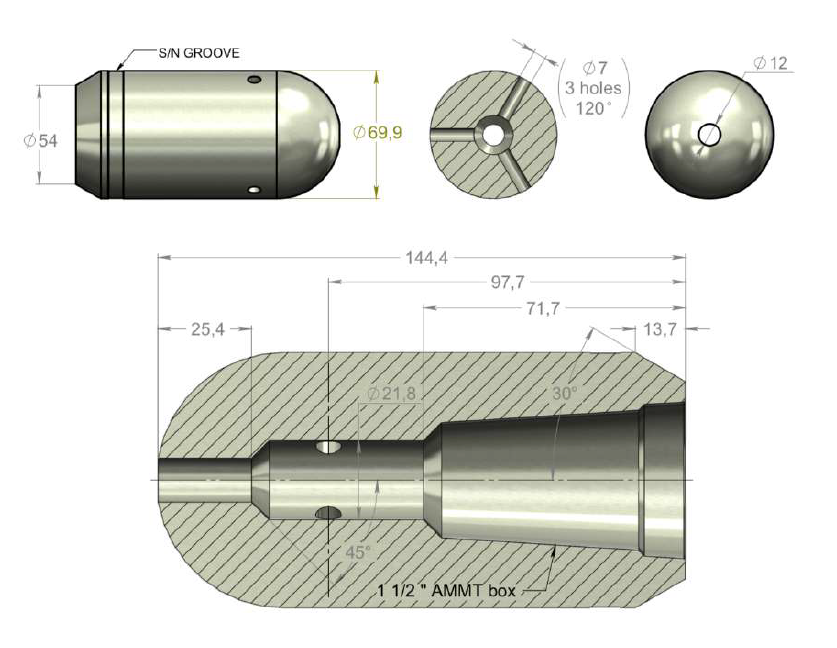

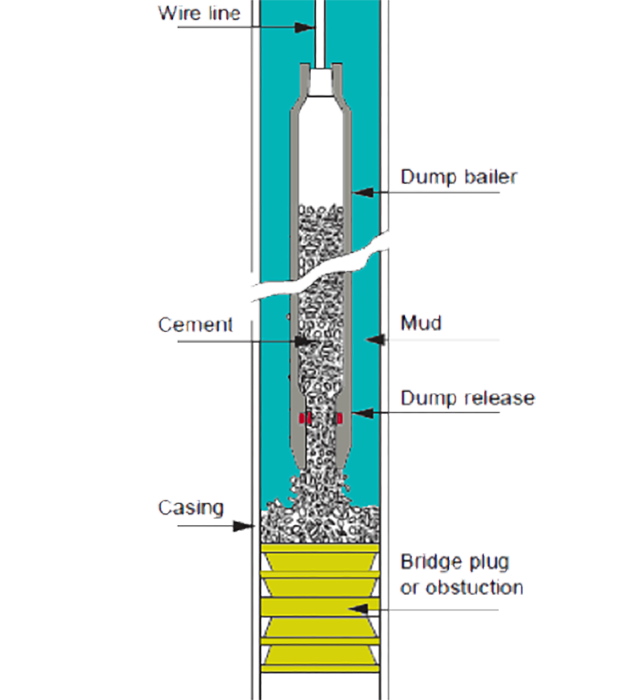

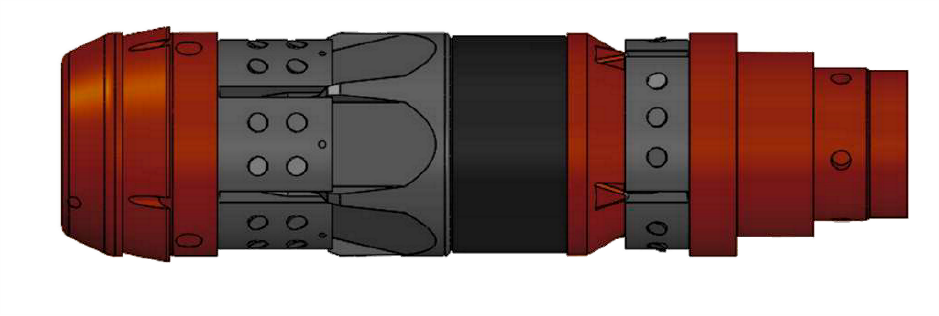

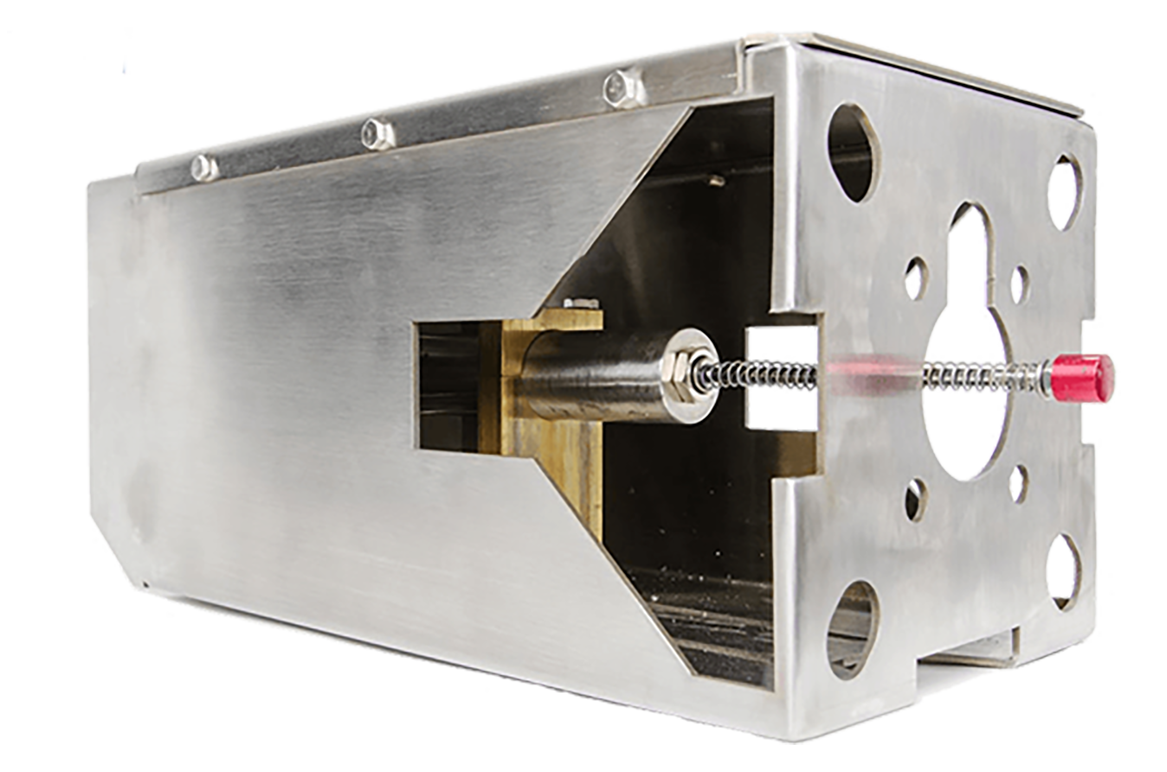

Accelerating Well Recovery with InWaTec Combined's Explosive Cutter Services In the demanding field of oil and gas extraction, time is a resource just as precious as the commodities we extract. For operations facing the challenge of stuck pipe, rapid and decisive action is paramount. InWaTec Combined’s Explosive Cutter Services offer a swift and effective solution to sever tubing and expedite the removal of obstructions, ensuring operational continuity and minimizing costly downtime. Stuck pipe scenarios are not just inconvenient—they are costly disruptions that can jeopardize the integrity of the well and escalate operational expenses. Our Tubing/Drill Pipe Cutters are designed to address these incidents with unmatched efficiency. When tubing becomes immovable, our cutters are deployed to deliver a clean, precise cut, allowing for the quick retrieval of the stuck sections. The selection of the cutter is a critical decision, and our technical experts are adept at determining the optimal diameter that can navigate the wellbore and deliver maximum performance. The largest possible cutter that the well can accommodate is used, ensuring that the cut is complete and that the well integrity is maintained throughout the operation. InWaTec Combined’s cutter technology is a blend of high-grade materials and explosive precision, a formula that guarantees a cut above the rest. Our cutters are not merely tools; they are the bearers of efficiency and effectiveness, embodying our commitment to providing solutions that keep your operations on track. Safety is paramount in all our explosive cutting operations. We rigorously adhere to the highest safety standards, ensuring that every cutter deployment is conducted with the utmost regard for the well's structural integrity and the surrounding environment. Our clients can rest assured that our Explosive Cutter Services are not only effective but are executed with an unyielding commitment to safety protocols. Choosing InWaTec Combined's Explosive Cutter Services means opting for a partner who understands the urgency and intricacies of well recovery. We bring expertise, precision, and reliability to the fore, ensuring that even in the face of challenging stuck pipe situations, your operations can swiftly resume. Let us bring our cutting-edge solutions to your wellsite, and together, we can overcome the obstacles that stand in the way of productivity and progress.

Service

In Stock

Service

New

API

Land Freight

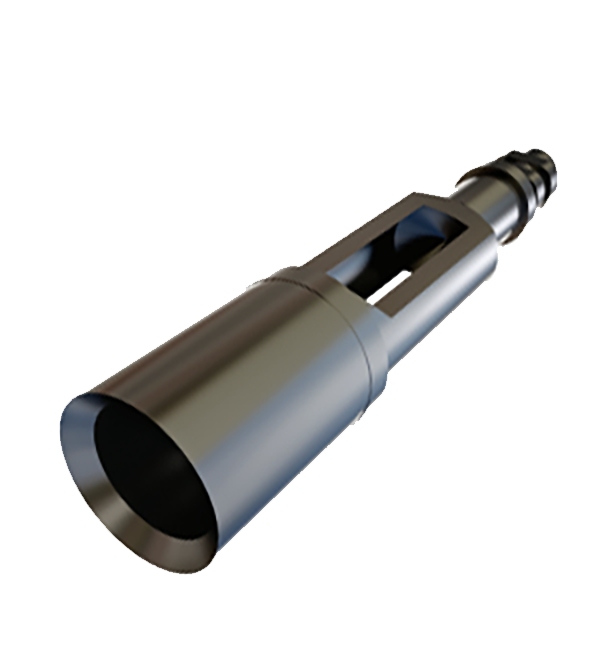

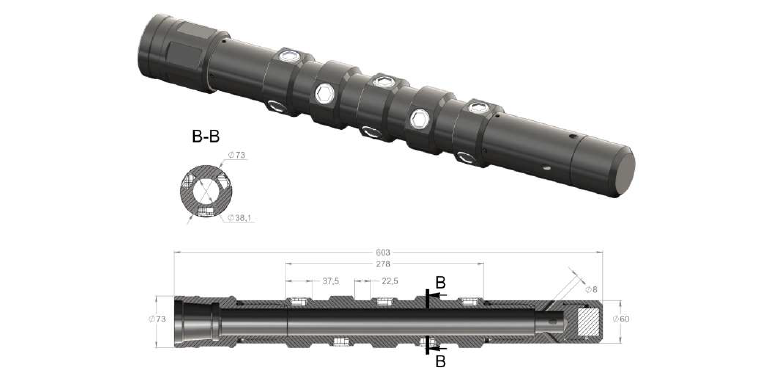

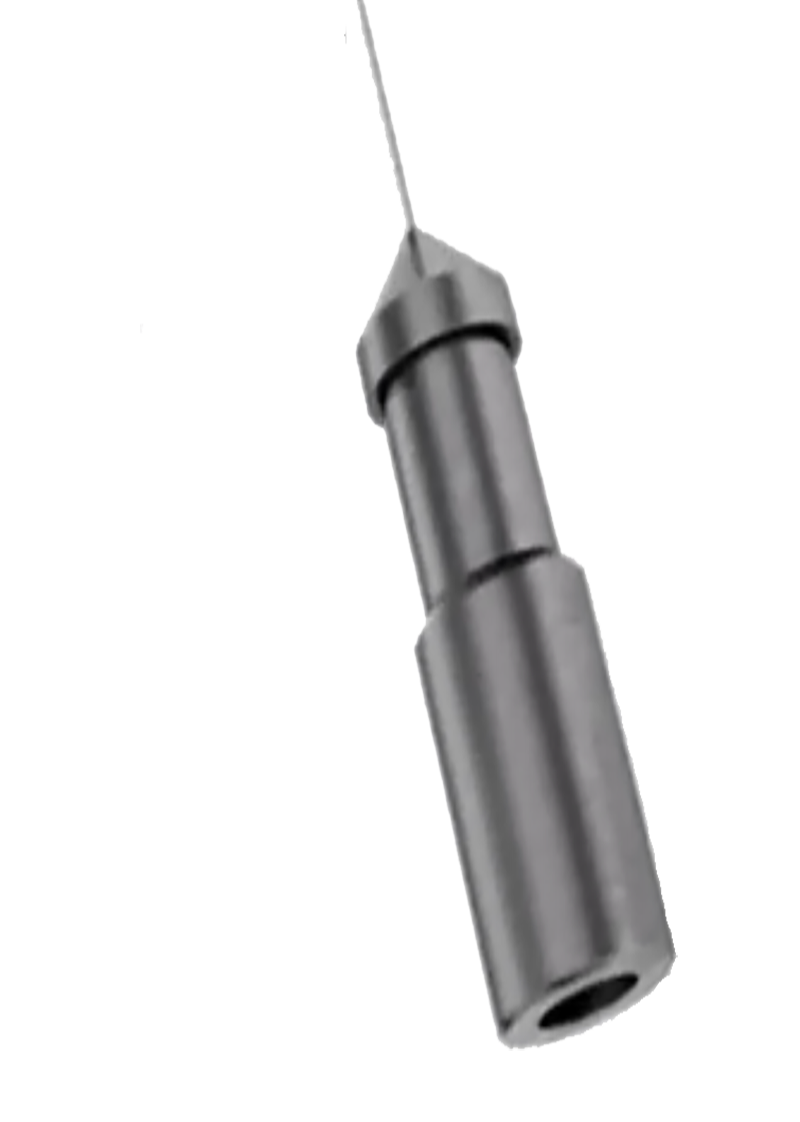

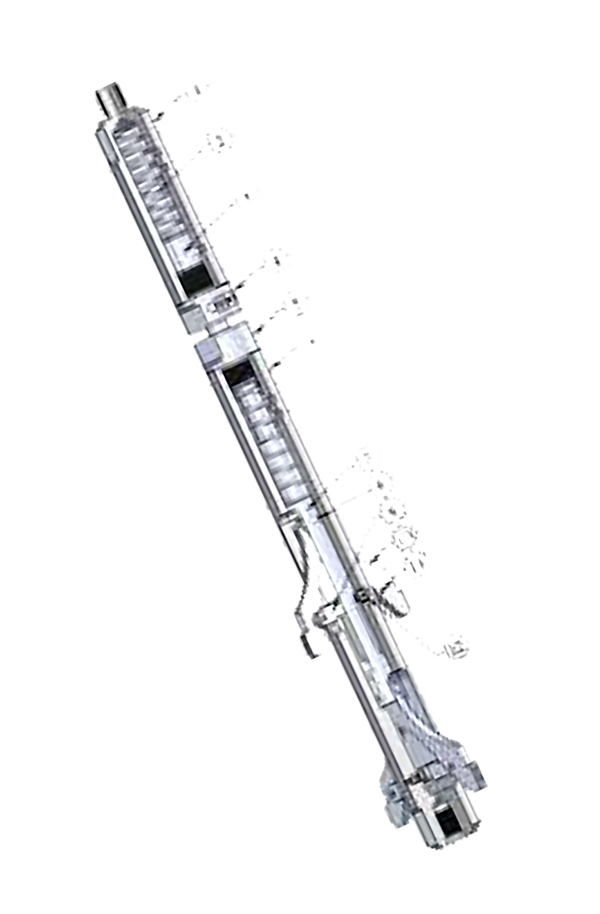

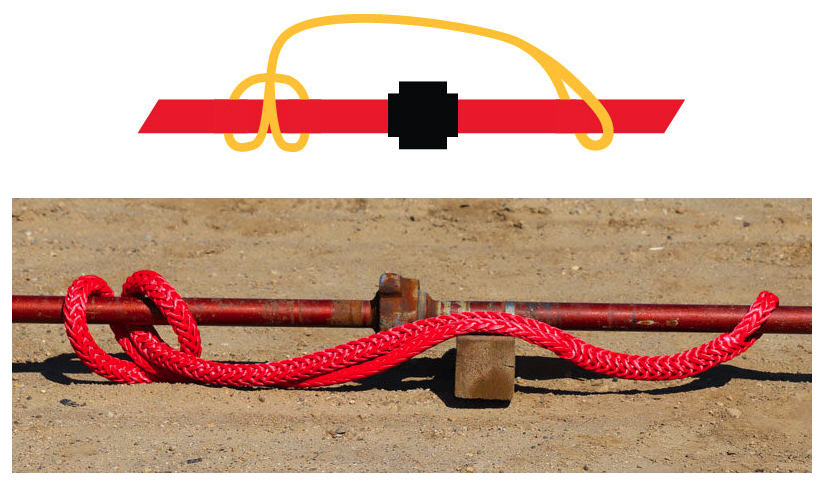

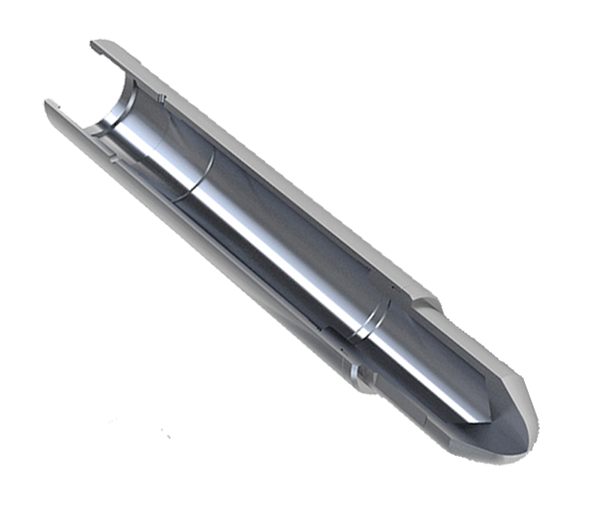

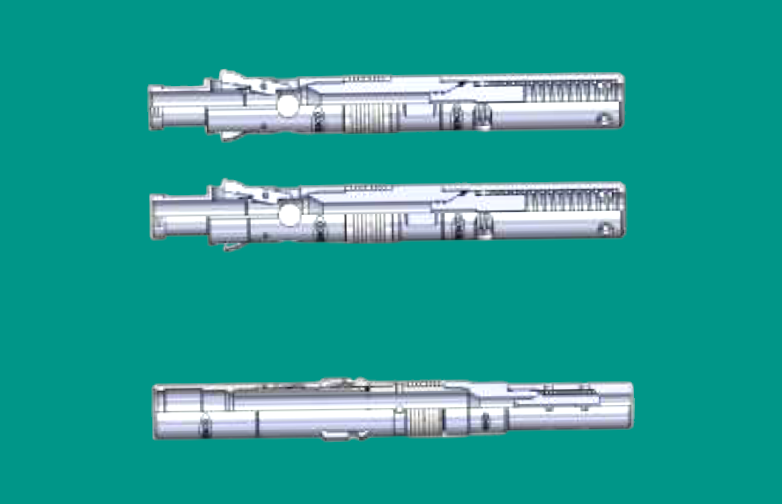

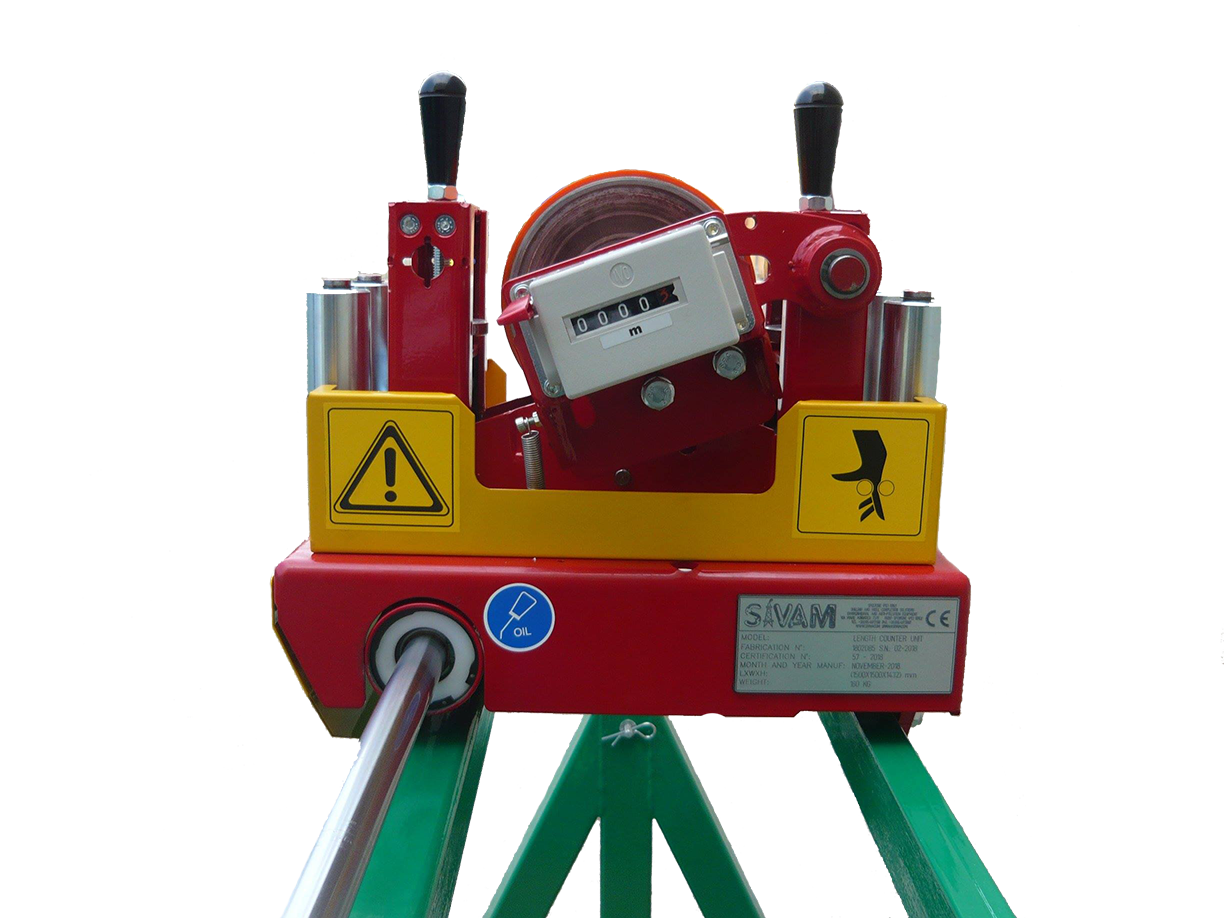

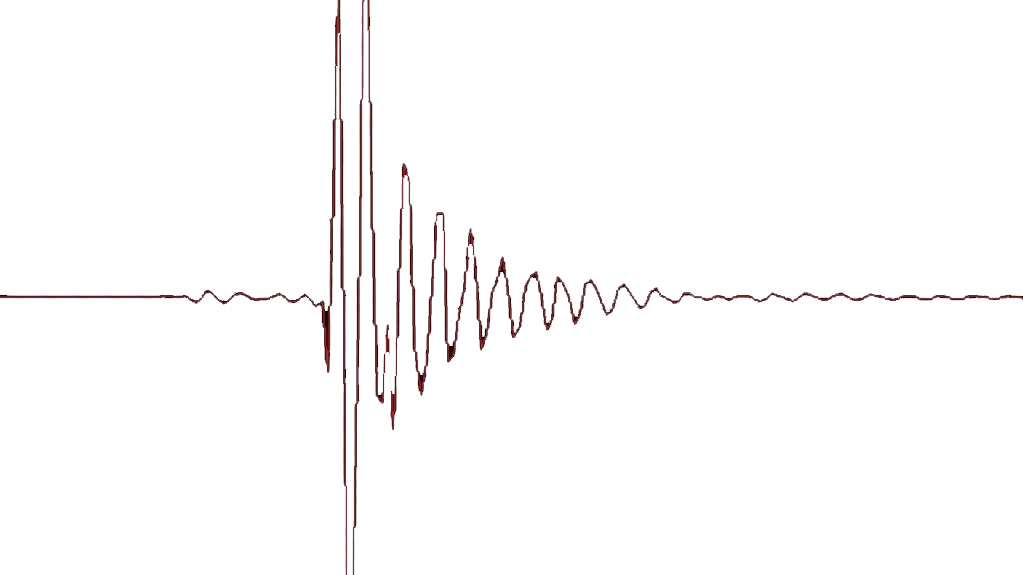

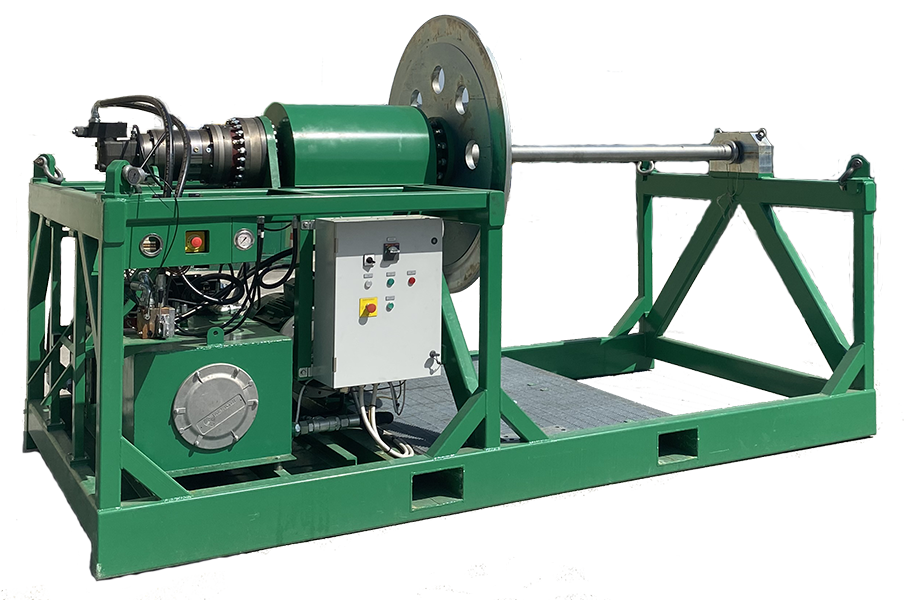

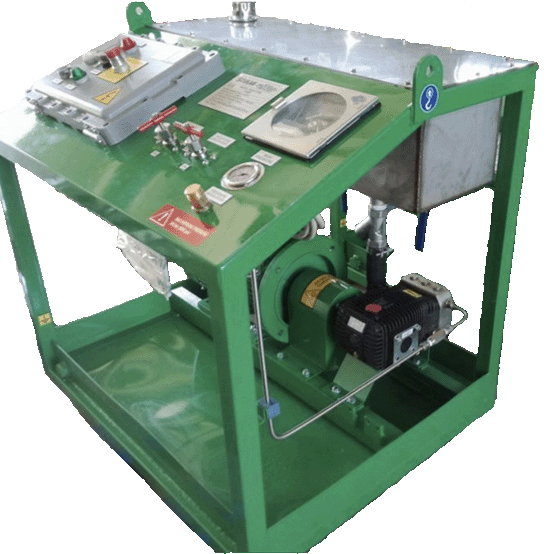

Wireline Services

InWaTec Combined: Pinpoint Precision with Tubing End Locator Services Accuracy is the cornerstone of successful well intervention and maintenance operations, and InWaTec Combined’s Tubing End Locator (TEL) running services exemplify this precision. Our TEL services provide clients with the certainty needed for depth correlation and critical downhole positioning, ensuring that all subsequent interventions are executed with pinpoint accuracy. The Crucial Role of the Tubing End Locator The TEL is an invaluable tool in the oil and gas industry’s arsenal, designed to accurately locate the end of the tubing string. This precise location is essential for depth correlation during various well servicing operations. InWaTec Combined's TEL services ensure that your team has the exact measurements necessary for efficient and effective intervention planning. Preparation for Precision Before deploying the TEL, it's crucial to ensure the tubing is clear of any debris that could obstruct the locator. InWaTec Combined’s preparatory procedures, which include running a gauge cutter or bailer, are meticulous steps that guarantee the TEL can smoothly navigate to and through the end of the tubing. This thorough clearing is part of our commitment to precision – we ensure that when the TEL is deployed, it operates in an unimpeded environment. Adaptable and Versatile Tooling Our TELs are equipped with a spring-loaded finger, enabling them to be run in various tubing sizes, ranging from 2-3/8? to 5-1/2?. This adaptability makes InWaTec Combined’s TEL services universally applicable, providing versatility without compromising on the accuracy of the tool. Whatever the tubing size, our TEL services can be tailored to meet the specific needs of the operation. Streamlining Operations with Accurate Measurements The accuracy provided by our TEL services streamlines subsequent operations by providing a reliable reference point. This eliminates guesswork, reduces the risk of error, and enhances the efficiency of operations such as setting packers, plugs, or perforating at precise depths. InWaTec Combined’s Promise of Excellence At InWaTec Combined, we understand the impact that accurate depth measurements can have on the success of well operations. Our TEL running services are a reflection of our promise to deliver excellence in every aspect of our work. We provide not just a service, but a partnership that enhances and ensures the precision of your well servicing tasks. Conclusion: Your Partner in Depth Correlation In conclusion, InWaTec Combined’s Tubing End Locator services are crucial for any operation that demands exact depth measurements. With our state-of-the-art tools and meticulous preparation, we ensure that every intervention is carried out with the confidence that comes from knowing the exact parameters of your well. Partner with InWaTec Combined, where precision is not just a metric; it's a mission.

Rental

In Stock

Product

New

API

Land Freight

Personal FX Services

Unlock Financial Freedom with Dunbridge Financial: Simplified Repatriation of Funds Are you an expat looking to make purchases back home or an immigrant wanting to send money to your family? Dunbridge Financial is here to make your financial dreams a reality. With our Personal Services, we offer a seamless and secure way to repatriate funds, ensuring that your hard-earned money reaches its destination with ease. Repatriation of Funds Made Easy Being away from home shouldn't mean being disconnected from your financial commitments and loved ones. At Dunbridge Financial, we understand the importance of staying connected to your roots and supporting your family. Whether you're an expat looking to invest back home or wanting to send financial assistance to your loved ones, our services are designed to cater to your needs. Personal Services for Your Peace of Mind At Dunbridge Financial, we take pride in offering comprehensive Personal Services that cater to your specific financial needs. Here's why our customers choose us: 1. Live Rates with No Hidden Fees Transparency is at the heart of our services. When you choose Dunbridge Financial, you won't encounter any hidden fees. What you see is what you get - access our live exchange rates and be confident that you're getting the most value for your money. 2. Security is Our Priority Your financial security is paramount to us. We partner with payment service providers who adhere to ISO27001 compliance, ensuring that your funds and data are managed safely and securely. Enjoy peace of mind knowing that your financial transactions are in trustworthy hands. 3. Easy to Use, Easy to Save Managing your international transactions should be effortless. With Dunbridge Financial, it is as simple as it gets. Sending money to over 100 countries is just a few clicks away. Select your destination, choose the recipient, lock in your exchange rate, and you're done! Saving time and money has never been easier. Why Choose Dunbridge Financial? We are more than just a financial service provider - we are your reliable partner in managing your personal finances. When you choose Dunbridge Financial, you gain access to: • Cutting-edge technology for smooth and efficient transactions • Expert guidance from our dedicated team, ensuring your needs are met • Secure and compliant processes that prioritize your financial well-being Join Us Today and Embrace Financial Freedom Embrace a world of financial freedom with Dunbridge Financial. Sign up now and experience a seamless, worry-free financial journey. If you're repatriating funds as an expat we are here to make your financial aspirations come true. Simplify your repatriation of funds with Dunbridge Financial. Unlock a world of possibilities with ease, convenience, and security. Your financial goals are within reach - join us today and make them a reality.

Service

Made to Order

Service

New

ISO

Air Freight

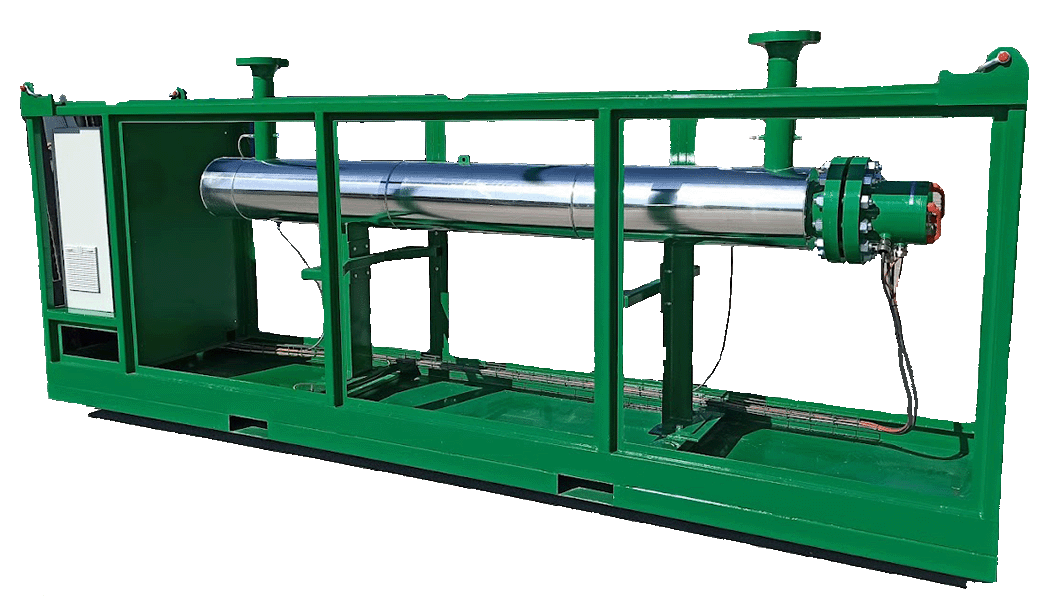

Back Pressure Turbine

Elevate Your Energy Solutions with the Kessels MS-52 Multistage Steam Turbine: Unleash Power, Precision, and Performance In the ever-evolving realm of steam turbine technology, Kessels Steam Turbines stands as a beacon of innovation and excellence. For the oil and gas industry, where power and precision are paramount, our MS-52 Multistage Steam Turbine is the ultimate solution – engineered to surpass expectations and redefine industry standards. Dominating Back Pressure Turbines Back pressure turbines, available in both single-stage and multi-stage configurations, serve as the vital link between boiler units and process steam headers. These turbines are the backbone of industries that demand a copious amount of steam, revolutionizing the utilization of steam and electricity generation. The Art of Efficiency At the heart of the MS-52 Multistage Steam Turbine is the hallmark of back pressure turbines: the straight-back pressure design. This engineering marvel ensures the seamless harnessing of exhaust steam, matching process demands with unparalleled precision. Every unit of electrical power generated is consumed as per the process steam demand, making it a pinnacle of efficiency. Applications Without Limits Our MS-52 turbine is not just a machine; it's a versatile workhorse ready to excel in various applications: Drive Applications: Whether in the oil and gas sector, sugar mills, sugar fibrizor systems, shredder drives, pump drives, or beyond, our turbine delivers power where it's needed most. Power Generation Applications: Take a giant leap towards sustainability by utilizing our turbine to generate electricity. It powers generators with clean and efficient steam energy, reducing your carbon footprint. Bleed Back-Pressure Steam Turbines At Kessels, we understand that adaptability is key. Our MS-52 turbine comes equipped with built-in bleed points, enabling uncontrolled extraction of steam within a medium pressure range. This feature proves invaluable when low-volume steam demands and high tolerance for pressure variations are the order of the day. Kessels turbines seamlessly blend the best of both bleed and back-pressure mechanisms. Extraction Back-Pressure Steam Turbines For industries with substantial process steam demand volumes and zero tolerance for pressure variations, our steam turbines with controlled extraction vents come to the forefront. Operating efficiently under intermediate pressure levels, these turbines ensure a steady and reliable steam supply that your operations can depend on. The Kessels Advantage Choosing Kessels Steam Turbines is more than a business decision; it's a choice of a partner committed to your success. Our MS-52 Multistage Steam Turbine embodies our unwavering dedication to innovation, performance, and customer satisfaction. Key Benefits of the MS-52 Multistage Steam Turbine: Unparalleled Efficiency: Maximize steam utilization while minimizing waste. Reliability Redefined: Built with precision and rigorously tested to ensure uninterrupted operations. Unmatched Versatility: Adapt effortlessly to changing needs, be it for drive applications or sustainable power generation. A Greener Future: Harness steam power for electricity generation, reducing your environmental impact. Dedicated Support: Our team of experts is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the competitive world of the oil and gas industry, every advantage matters. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-52 Multistage Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward a future of success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

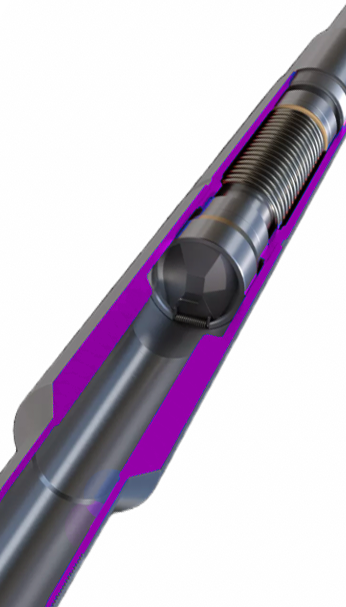

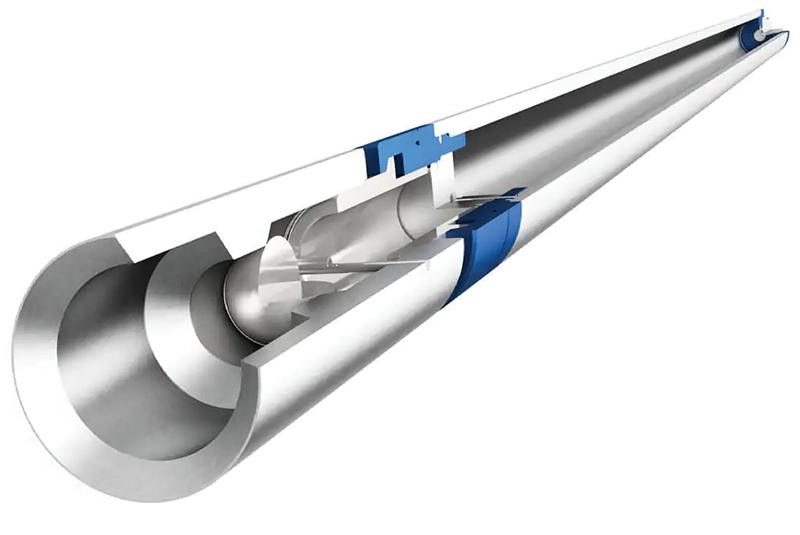

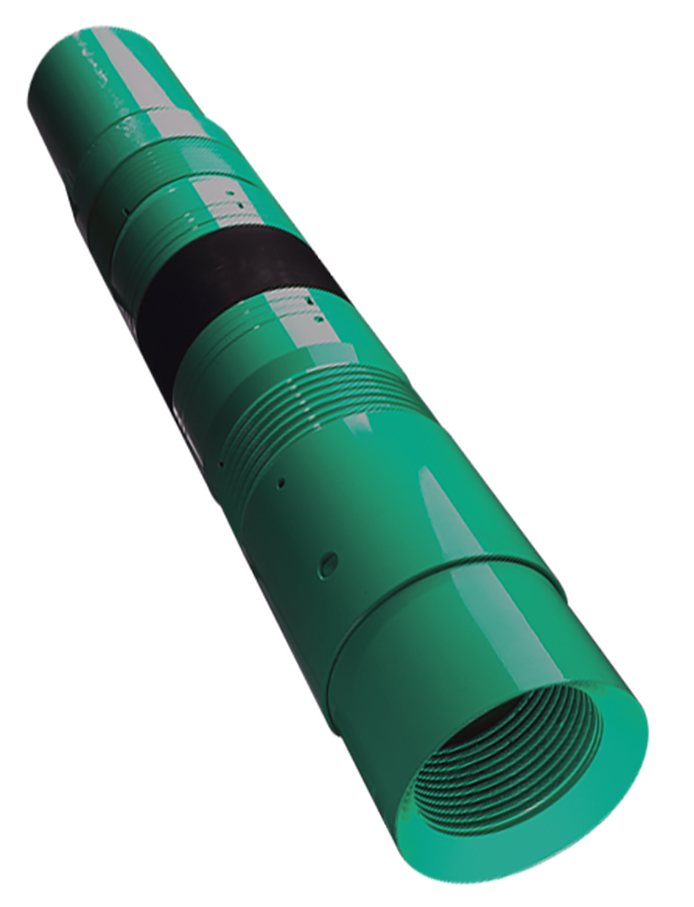

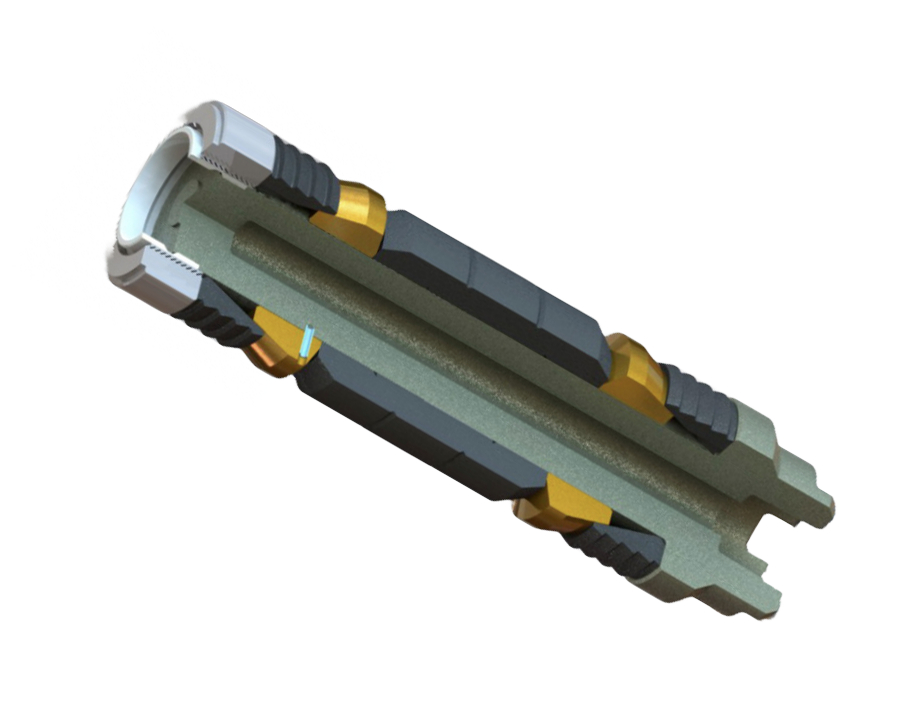

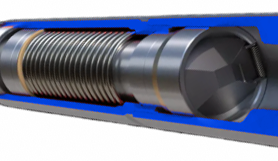

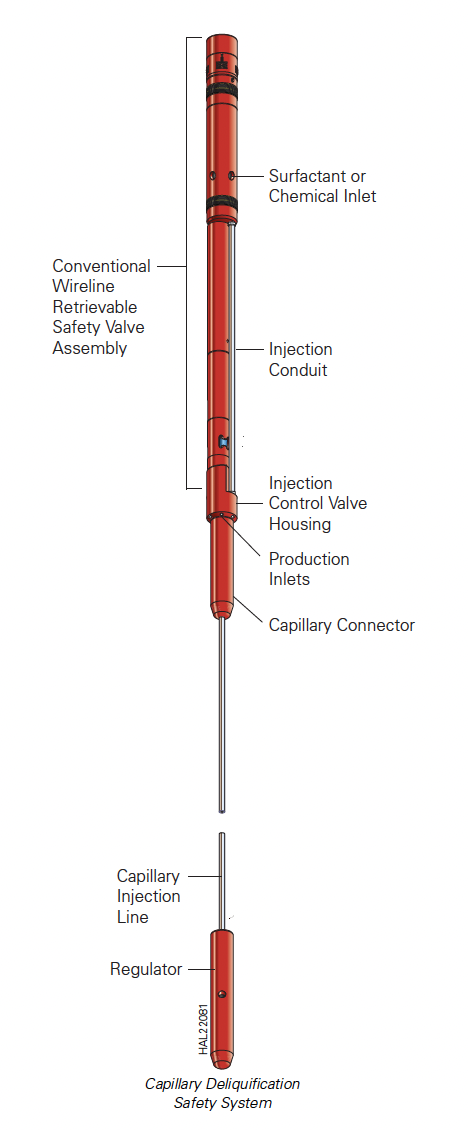

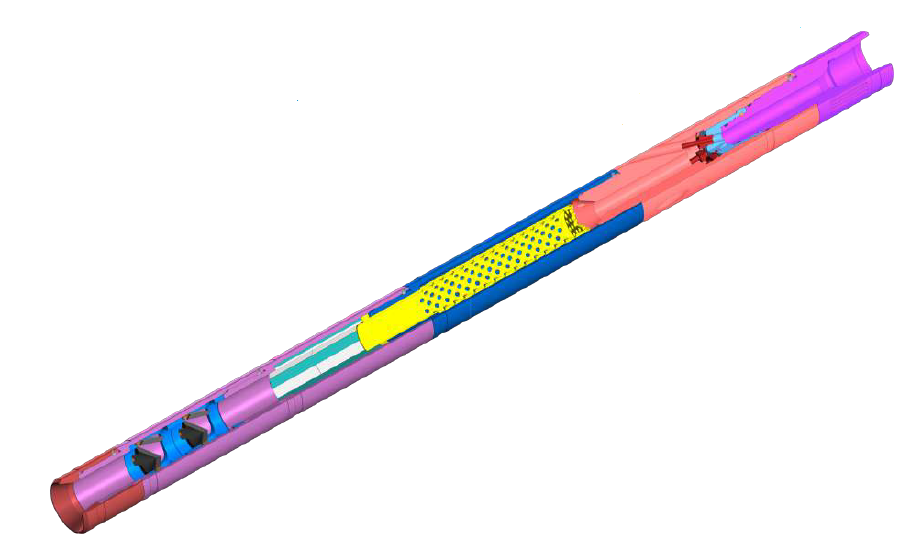

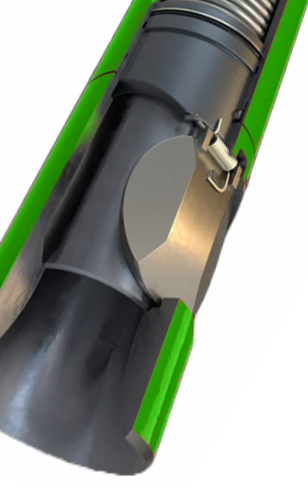

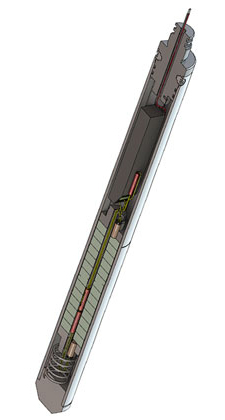

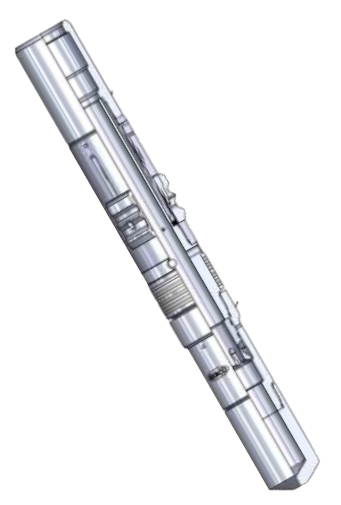

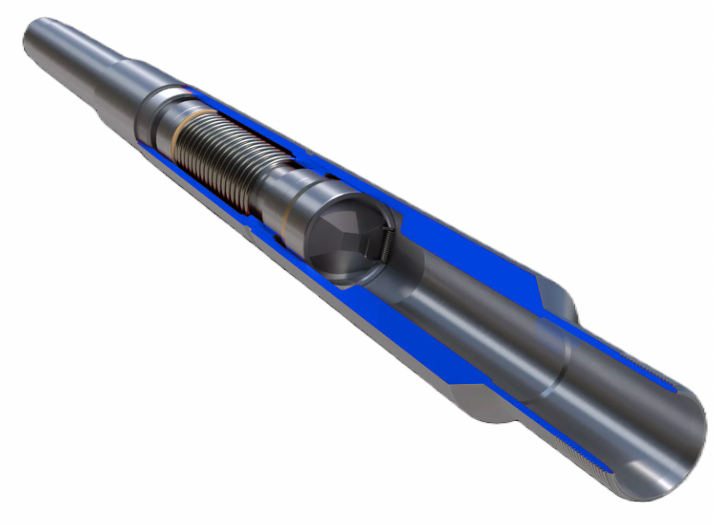

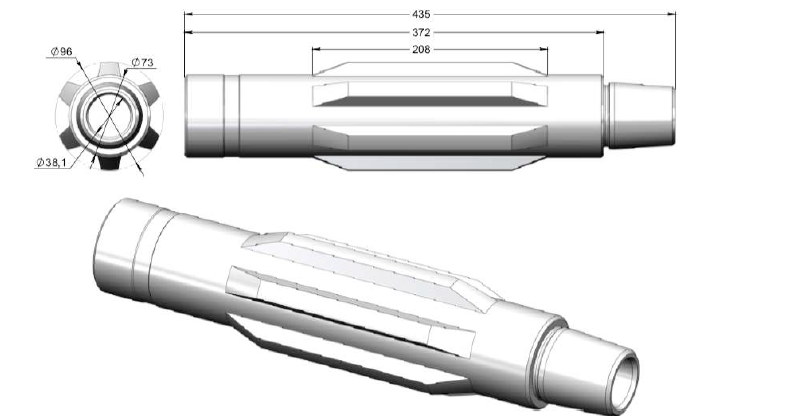

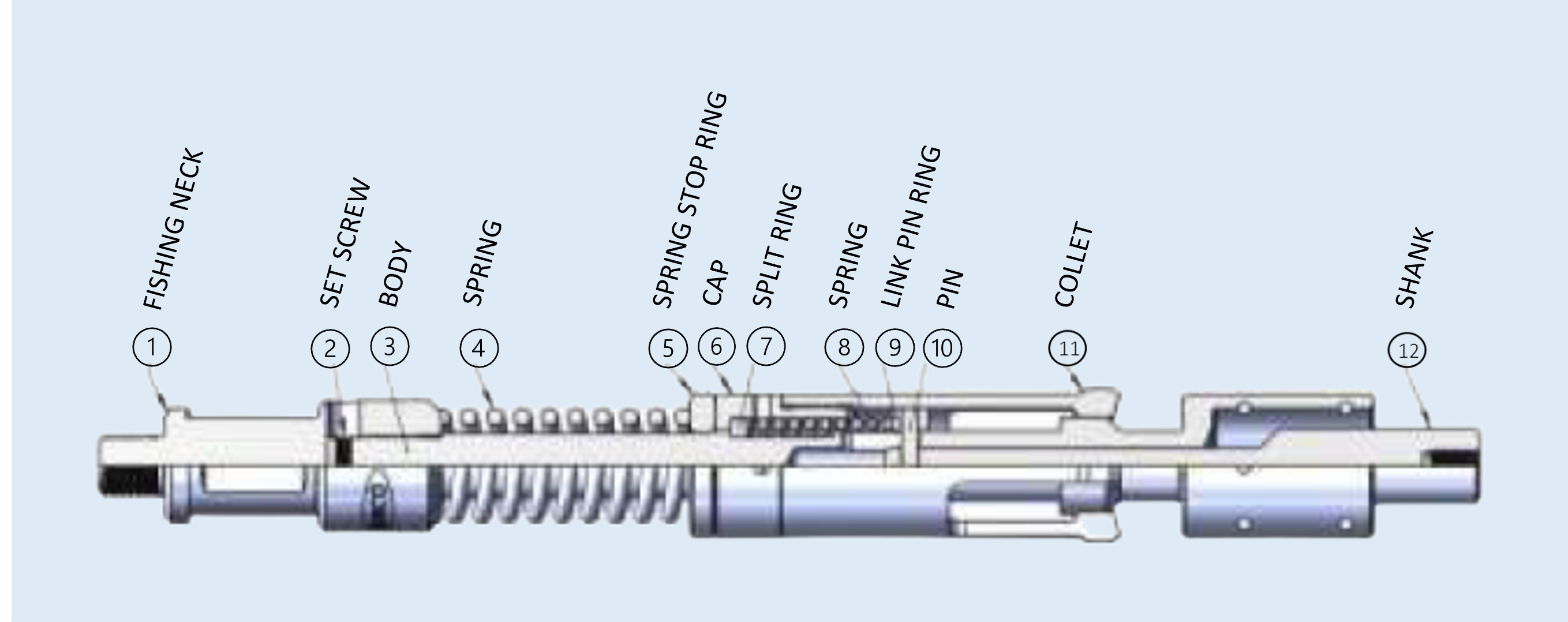

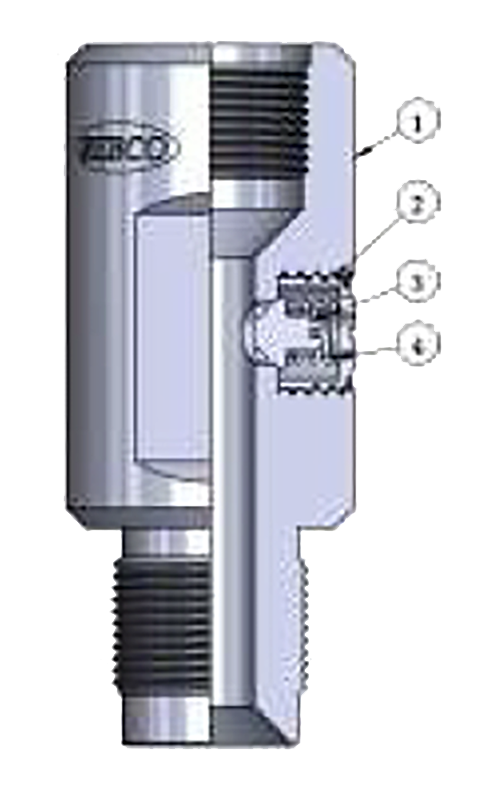

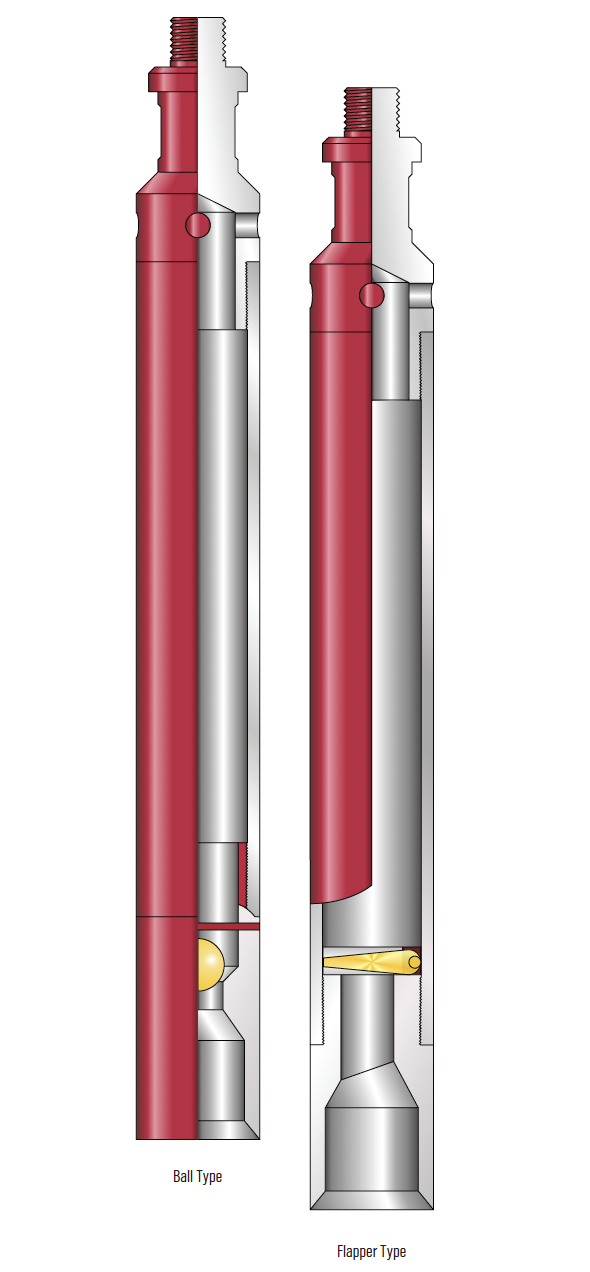

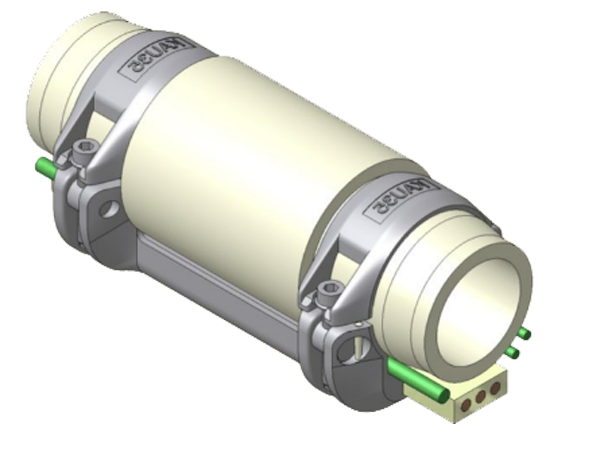

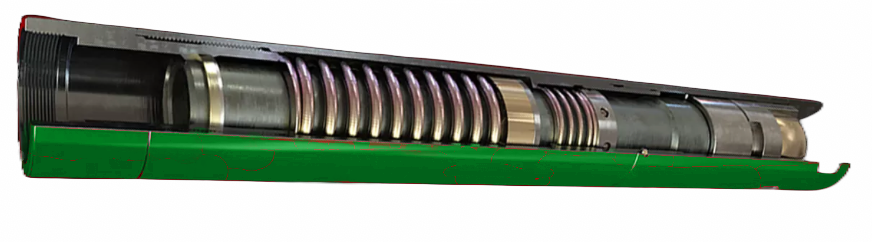

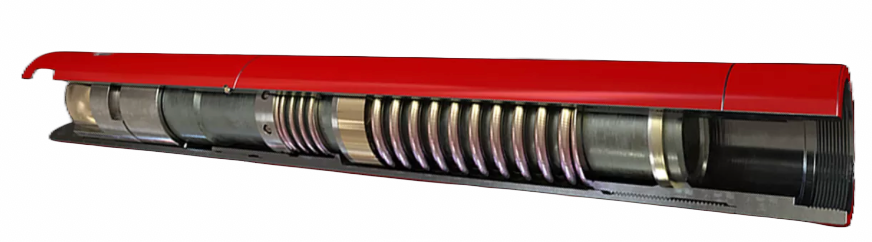

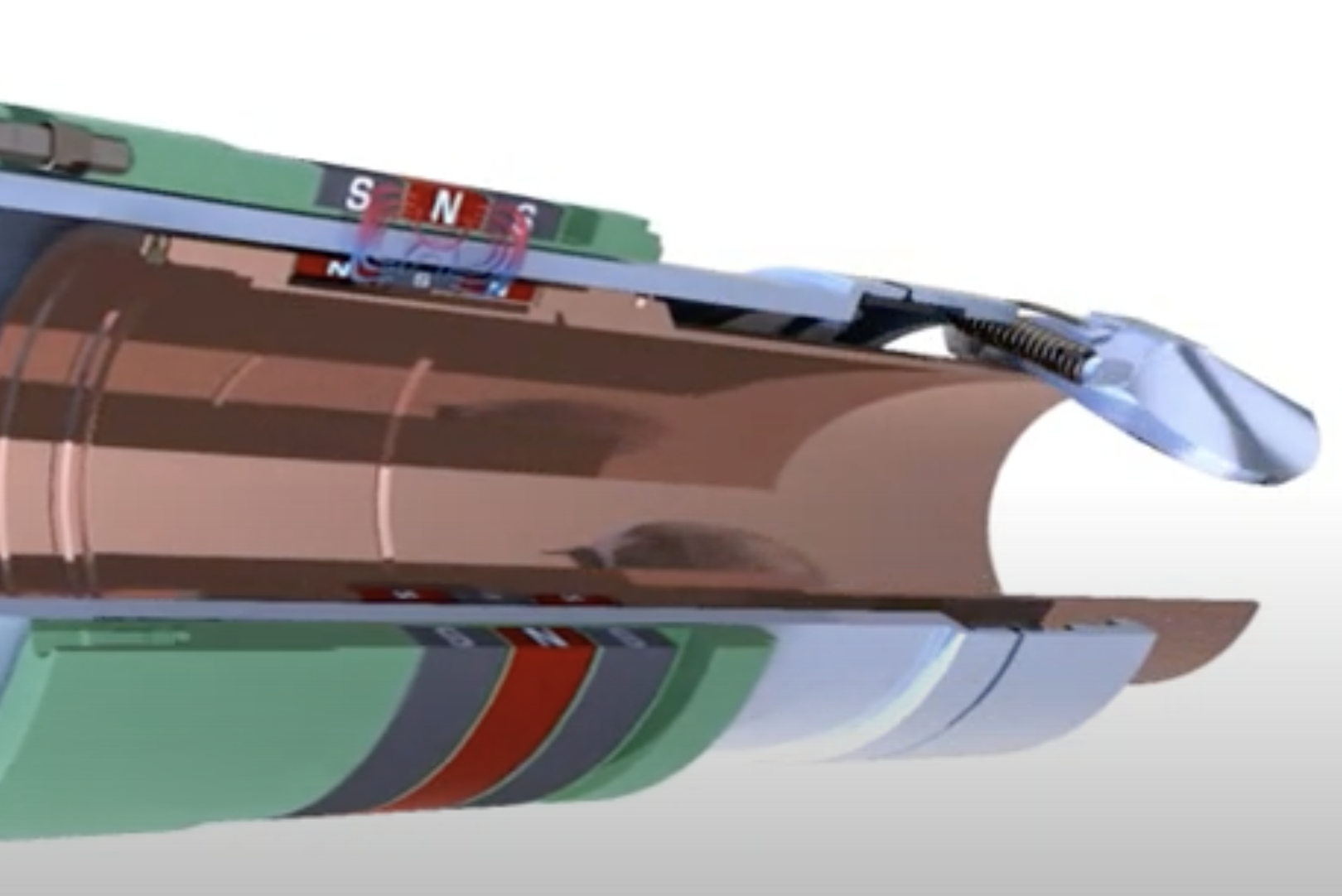

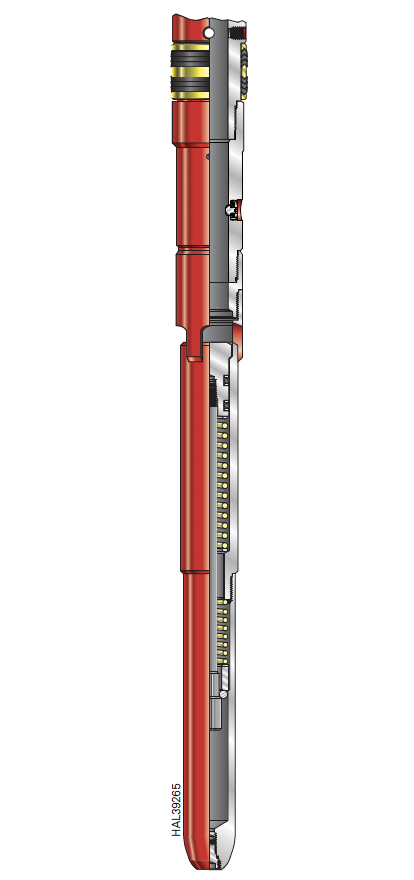

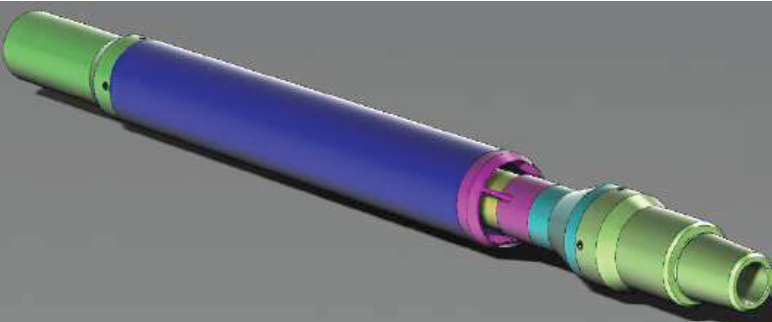

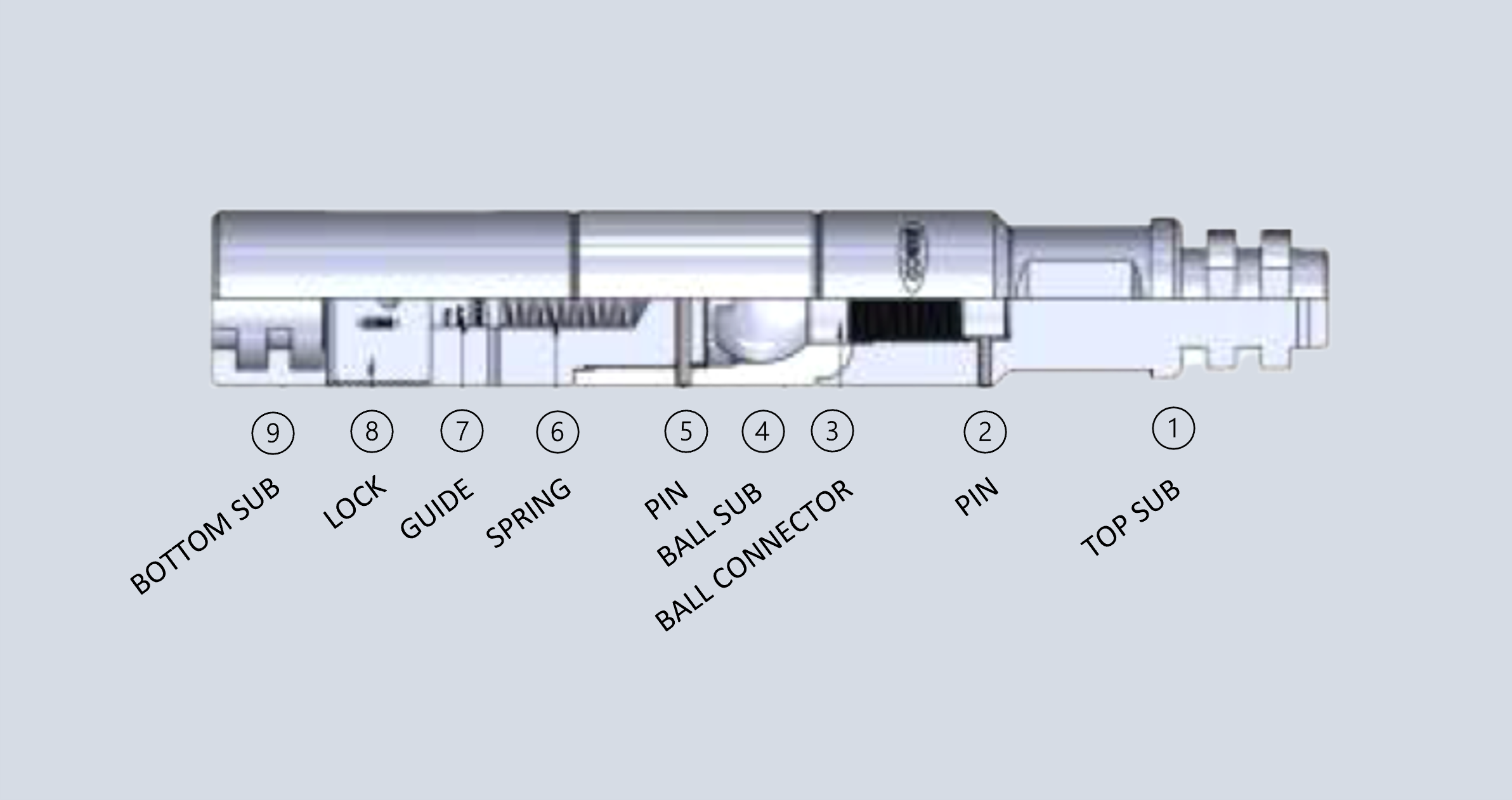

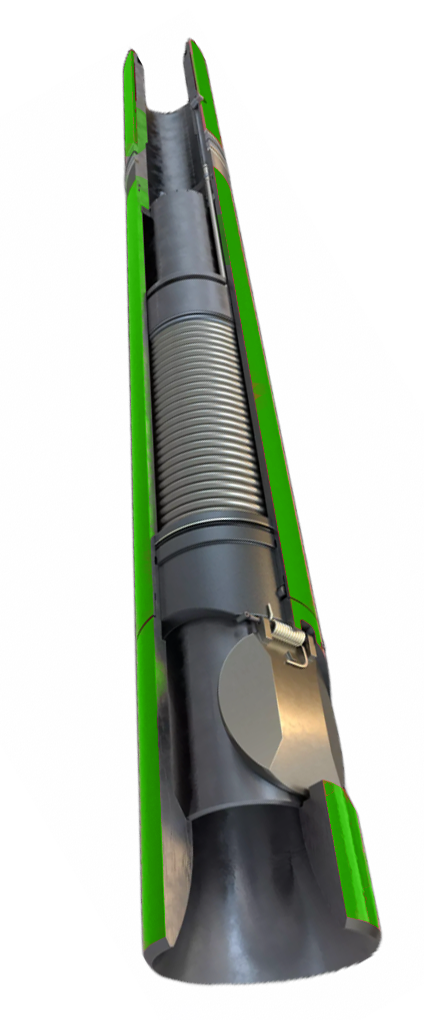

TR-SCSSSV SP

The SP™ tubing-retrievable safety valve (TRSV) is a single rod-piston non-elastomer flapper valve designed for hostile environments and extended life applications where ultimate reliability is required. Potential leak paths within the valve are minimized with the single rod-piston design. The piston achieves a metal-to-metal (MTM) seal at its uppermost and lowermost positions to seal well pressure from the control system. The SP valves incorporate flappers using spherical radius sealing surfaces that help greatly improve seal reliability. The spherical radius design provides full MTM sealing integrity. For applications where either the OD or ID is restrained, SP valves incorporate a contoured flapper. OD/ID relationships are improved by the contoured flapper design, which helps provide superior MTM sealing when compared to other forms of curved flapper technology. Applications » For applications requiring ultimate reliability and longevity, such as high-temperature/high-pressure, and subsea completions, or hostile well environments Features » Non-elastomer dynamic piston seals » MTM static seal at upper and lower piston positions » MTM body joints » Flow tube fluted guide » 100% MTM flapper » Concentric thrust bearing » Wiper ring on upper flow tube » Cleanout ports in flow tube’s upper end » Internal exercise profile » Flow tube shock absorber » MTM face seat at flow tube downstop » Setting depths to 9,000 ft (2743 m) » Critical components isolated from well debris with valve in open position » Area above flow tube free of solids buildup » Flow tube can be manipulated by slickline » Protected from high flow rate slam closures *information referenced from supplier catalog.

Buy

Made to Order

Product

New

API

Air Freight

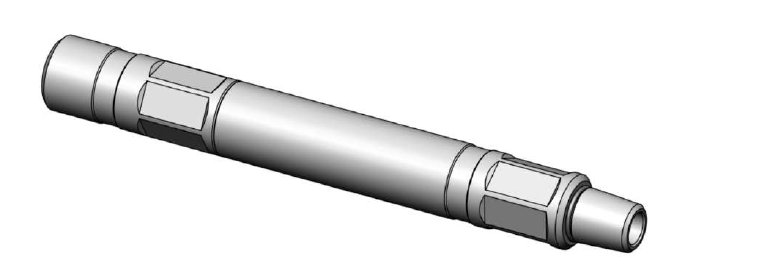

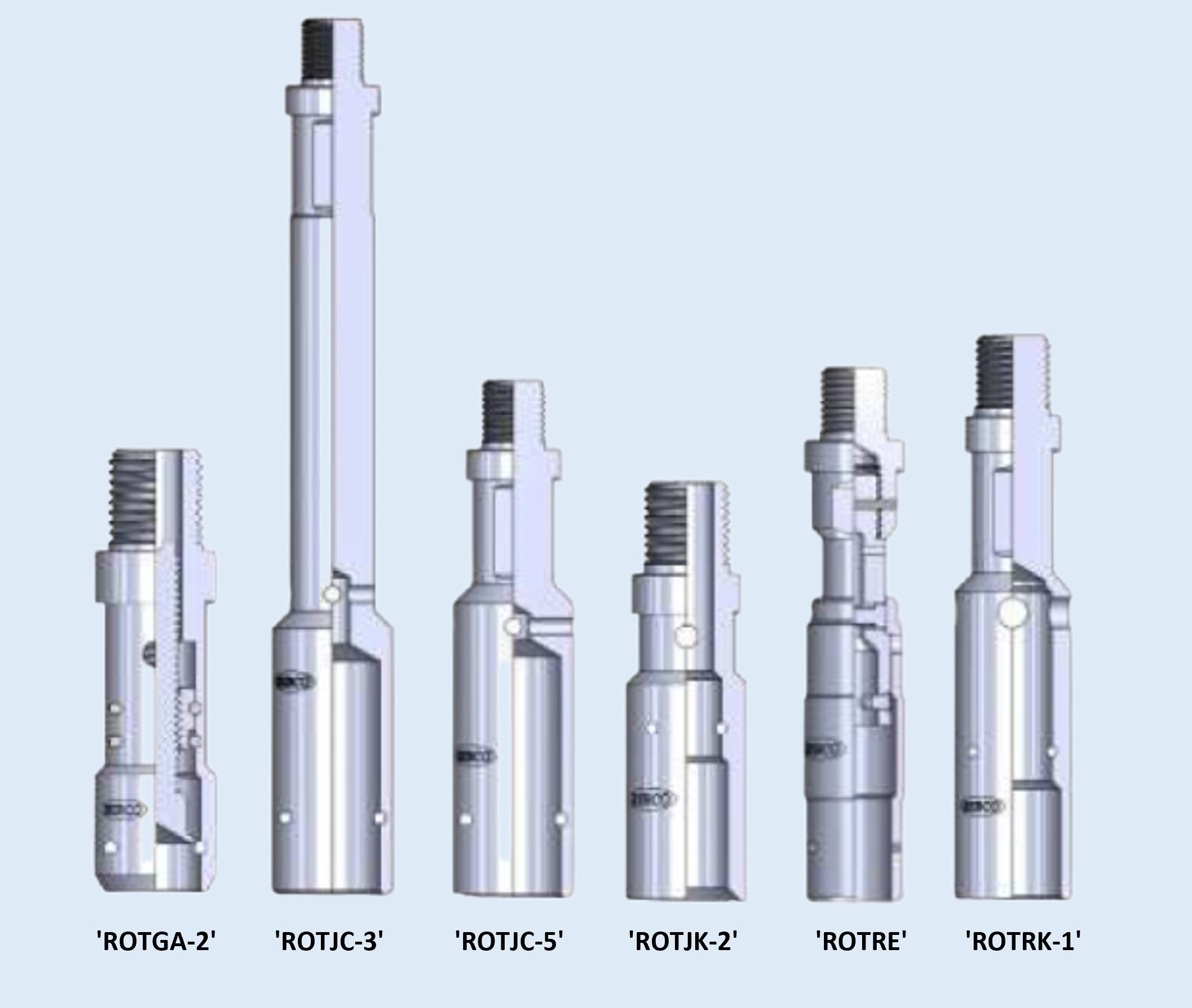

Downhole Tools

Elevate Downhole Operations with HOCA Oil Tools' Special Function Pulling Tools In the rapidly evolving landscape of oil and gas extraction, the right downhole tools can be the key to operational success and efficiency. HOCA Oil Tools understands this imperative and responds with our line of Special Function Pulling Tools, engineered to meet the unique challenges faced during downhole operations. Our specialized tools are designed not just to meet but to exceed the demands of modern well interventions, ensuring that every operation is as seamless and efficient as possible. HOCA’s Special Function Pulling Tools: Tailored Solutions for Unique Downhole Challenges Our Special Function Pulling Tools encompass a variety of designs, each tailored to address specific downhole needs and challenges. Whether it's retrieving stuck equipment, deploying complex assemblies, or performing precision interventions, our tools are crafted to provide solutions that enhance operational outcomes. Made with the highest quality materials and precision engineering, HOCA’s Special Function Pulling Tools are the embodiment of our commitment to innovation, quality, and reliability. Experience the HOCA Oil Tools Difference At HOCA Oil Tools, we are not just suppliers; we are partners in your downhole success. Our Special Function Pulling Tools are a testament to our dedication to advancing downhole operations through innovative solutions. By choosing our specialized tools, you are not only equipping your operations with top-tier downhole technology but also aligning with a partner dedicated to providing exceptional service and support. Incorporating HOCA’s Special Function Pulling Tools into your downhole operations is a step towards enhanced efficiency, safety, and cost-effectiveness. Our commitment to quality and innovation ensures that our tools stand up to the challenges of the oilfield, driving your operations to new heights of success. Opt for HOCA Oil Tools for your downhole needs and join the ranks of satisfied clients who depend on our Special Function Pulling Tools for their unique operational challenges. Elevate your downhole operations with HOCA Oil Tools – where exceptional quality meets innovative solutions.

Buy

In Stock

Product & Service

New

API

Air Freight

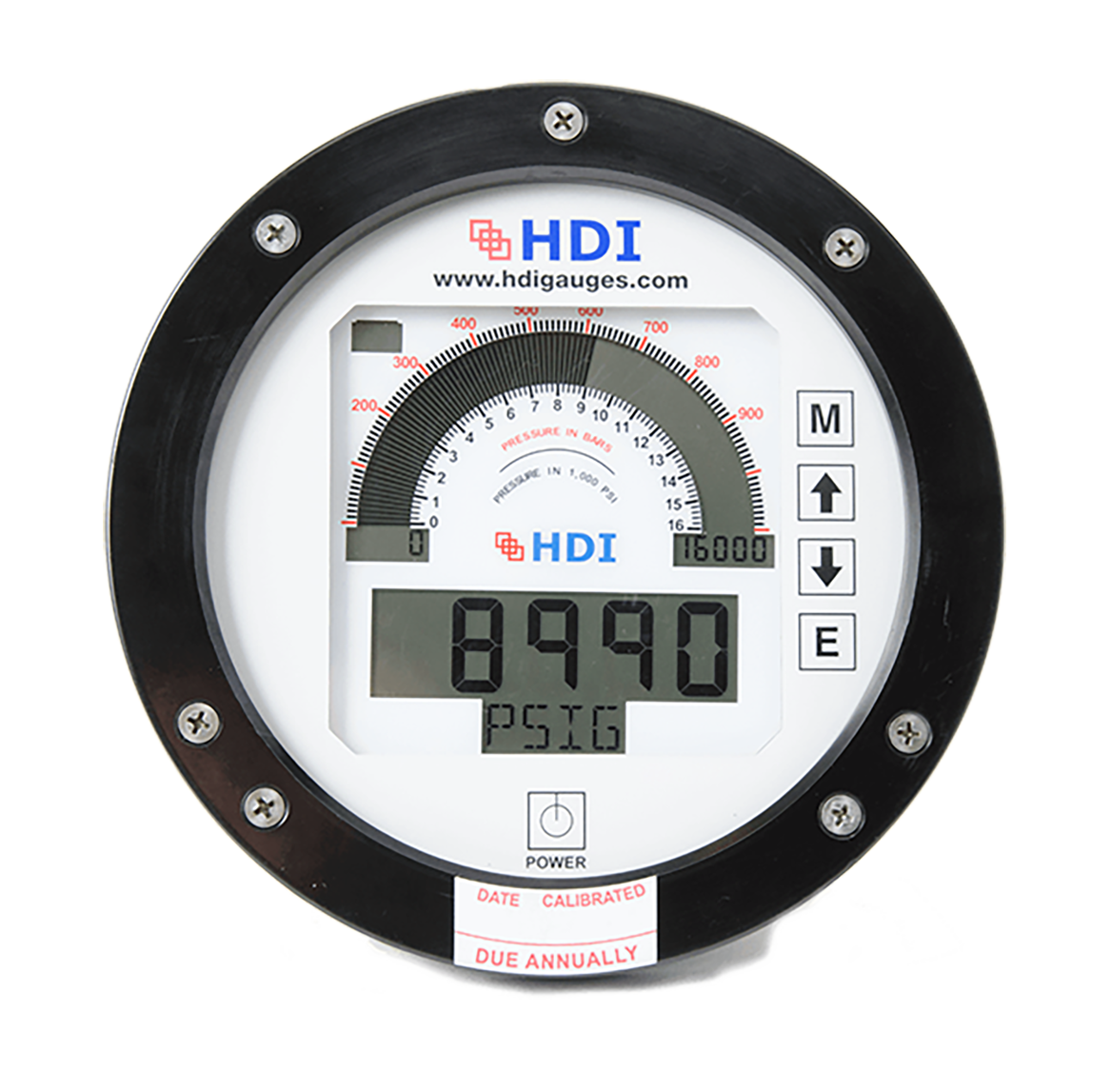

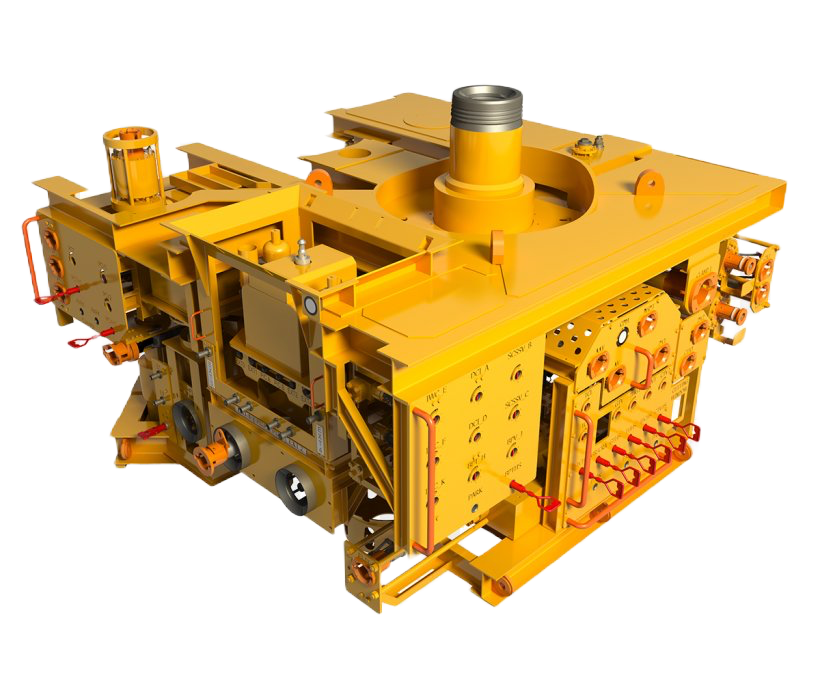

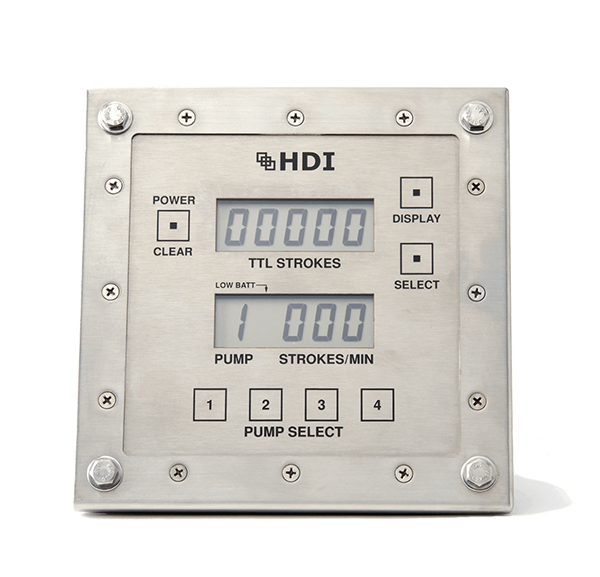

Remote Choke

Houston Digital Instruments (HDI Gauges) is proud to introduce the HDI V9000 Virtual Choke Console System, a state-of-the-art solution that revolutionizes control and monitoring capabilities for choke operations. Built on the foundation of the renowned HDI 9000 Choke Console System, the V9000 combines a user-friendly HMI interface with PLC-based technology to deliver unparalleled performance. Let's explore the features and advantages of this cutting-edge virtual console system. Advanced Control and Monitoring: At its core, the HDI V9000 Virtual Choke Console System offers a virtual representation of the HDI 9000 Choke Console System. This advanced system goes beyond monitoring capabilities and empowers users with the ability to control the HDI 9000 itself. By pairing the V9000's electronic joysticks with the 9000's hydraulic master valves, operators can locally or remotely control choke operations, providing precise and responsive control for enhanced operational efficiency. Flexibility and Customization: The HDI V9000 is designed to adapt to various client specifications, preferences, and space constraints. The system can be built on different console designs, allowing clients to tailor the V9000 to their specific requirements. Moreover, the V9000's flexibility extends to its inputs, accommodating additional parameters beyond those found on standard HDI 9000 Consoles. This includes inputs from HDI's 2250 Gate Valve Monitoring System, 3200 Mud Gas Separator Monitoring System, buffer pressure, riser pressure, sub-sea temperatures, miscellaneous pressures, and more. This versatility ensures comprehensive monitoring and control capabilities, tailored to the unique needs of each operation. Customizable Language Packages and Appearance: Recognizing the global nature of the oil and gas industry, the HDI V9000 offers full customization for language packages. Clients can select language options such as Russian, German, Portuguese, and more, enabling seamless communication and operation for international teams. Additionally, the appearance of the V9000 console can be matched to client-specific specifications, ensuring a cohesive and integrated visual experience that aligns with their branding and operational aesthetics. Seamless Integration and Future-Proof Design: The HDI V9000 Virtual Choke Console System seamlessly integrates with existing HDI 9000 Choke Console Systems, enhancing their functionality and control capabilities. This integration allows for a smooth transition to the V9000 while leveraging the investments made in the existing infrastructure. The system's future-proof design ensures compatibility with upcoming technological advancements and industry requirements, safeguarding clients' investments and providing a scalable solution for long-term operational needs. The HDI V9000 Virtual Choke Console System represents a significant advancement in control and monitoring technology for choke operations in the oil and gas industry. With its HMI interface, PLC-based functionality, and the ability to control the HDI 9000 Choke Console System, the V9000 offers unparalleled control, flexibility, and customization. Experience the power of advanced choke operation with the HDI V9000 and optimize your operational efficiency and safety. Contact HDI Gauges today to explore how the V9000 can revolutionize your choke control and monitoring capabilities.

Buy

In Stock

Manufacturer

New

API

Air Freight

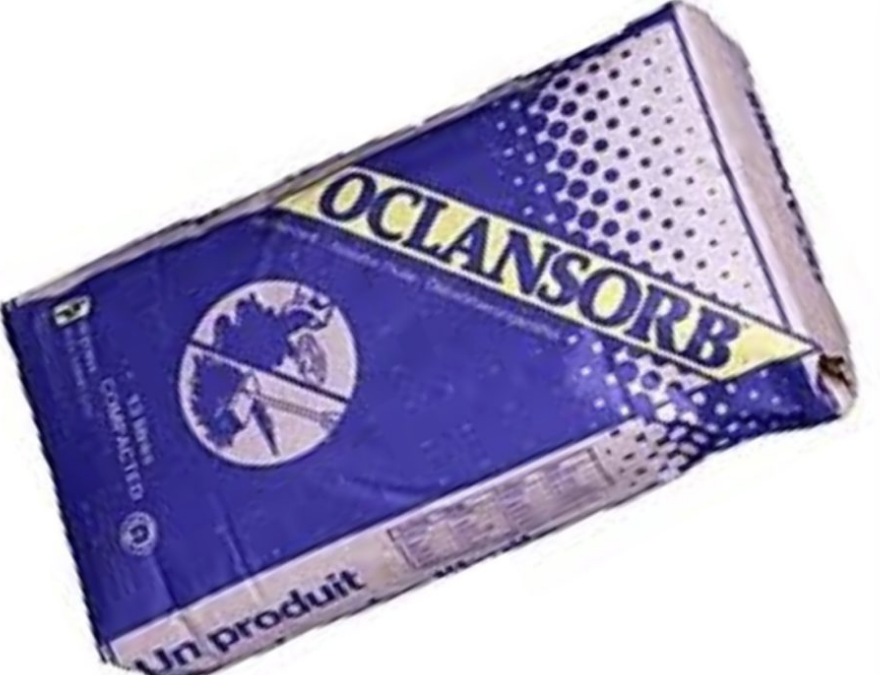

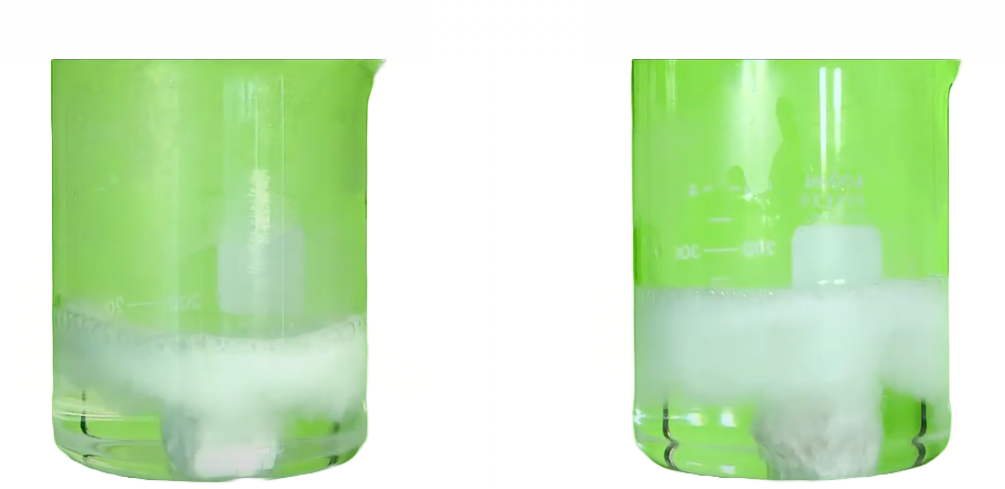

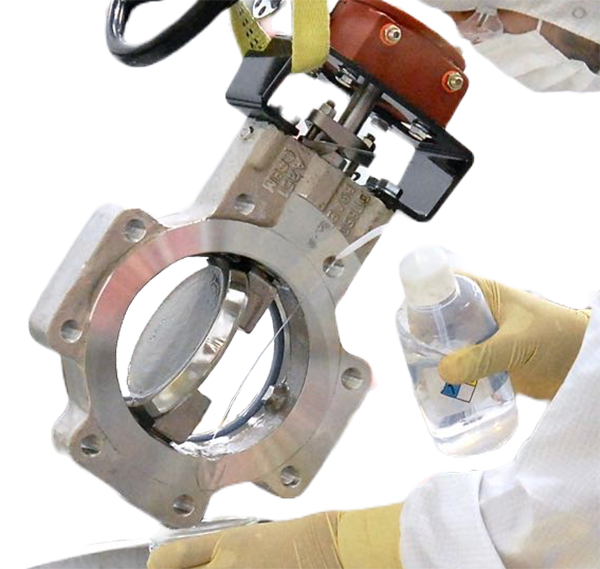

Mercury Cleaning

Mercury contamination can be a serious problem for many industries, but Cleanstream has the solution. Our specialized Mercury decontamination process uses green, non-corrosive chemicals to treat even the most complicated materials and objects, removing stubborn dirt and hard-to-reach areas. We take pride in using a release value of only 1mg/kg, ensuring safety and compliance with regulations. Before beginning any cleaning process, we take a sample of the contamination and examine it using XRF analysis in our internal laboratory. We share the results with our clients to ensure transparency and quality in our work. At Cleanstream, we understand the importance of cleaning without damage. Our experts are experienced workers who have developed inventive cleaning methods to ensure that materials are not damaged during the cleaning process. We also carefully disassemble materials for optimal cleaning, ensuring that every part is properly treated. We believe in sustainable solutions, which is why we take care of the removal of mercury-containing waste from decontamination. The cleaned materials can be reused or recycled for further use. Cleanstream is committed to providing fast and cost-effective services without compromising safety or quality. We are constantly improving our processes to reduce waste and provide green solutions. Join us in our mission to promote safety and sustainability in your industry. Contact Cleanstream today to experience our innovative and efficient Mercury decontamination process. With our safe, green, and effective solutions, you can trust us to deliver the best possible results for your business.

Service

In Stock

Service

New

ISO

Land Freight

Air Cooled MIG Welding Gun

Introducing the Revolutionary MIG Gun M250 Series: Your Ultimate Welding Companion When it comes to heavy-duty, durable, and high-performance MIG guns, look no further than the Canaweld M250 Series. Crafted with precision and innovation, this newly designed MIG gun sets a new standard in the welding industry. Engineered to meet the demands of the oil and gas industry, the M250 Series will transform the way you weld, offering unmatched versatility, comfort, and efficiency. Built for Excellence - Unleash the Power of Adaptability The M250 MIG gun boasts a unique and cutting-edge feature that sets it apart from the rest - the ability to convert termination styles seamlessly. With a simple replacement, you can switch between Euro style, Lincoln® style, Tweco® style, or Miller® style, ensuring compatibility with various welding machines. This adaptability makes the M250 Series a true game-changer for welders, offering unmatched flexibility in their welding projects. Unrivaled Features - Mastering Welding Precision Let's dive into the exceptional features of the Canaweld M250 Series: 1. Knuckle Joint: Experience improved balance and position-ability as the handle and neck move independently of the cable assembly. Weld with greater precision and control. 2. Durable Cable: The M250 MIG gun boasts excellent heat, abrasion resistance, and flexibility in its cable. It's lighter than standard cable sets and can withstand over 1 million flexes in life testing, ensuring it stands the test of time. 3. Premium Contact Tips: Crafted from premium grade copper alloys, the contact tips are extremely durable, offering superior performance and efficiency. 4. High-Quality Accessories: Choose from a range of durable and high-performance options for tip adaptors, diffusers, and swan necks, tailoring your MIG gun to suit your specific needs. 5. Ergonomic Handle Design: Enjoy comfortable handling with the ergonomic design of the handle, reducing welder fatigue and promoting longer welding sessions. 6. Air Gap Technology: The M250 MIG gun utilizes air gap technology for cooler running handles and better heat transfer isolator from the swan neck, ensuring efficient and effective welding. 7. Versatile Liner: The steel and combo liner cater to all types of wires, including steel (metalcore and flux-cored), stainless steel (metalcore and flux-cored), and aluminum, making it suitable for a wide range of welding applications. 8. Effective Sealing: The unique sealing ring ensures effective sealing of impurities, particularly in the argon gas process, promoting cleaner welds. 9. Push-on Nozzle System: Easily adjust nozzle stick-out with the push-on nozzle system, streamlining your welding workflow. 10. High-Quality Trigger: The M250 MIG gun comes with a high-quality trigger that boasts a life expectancy of over 1 million cycles, offering durability and reliability in every weld. Elevate Your Welding Experience with Canaweld M250 Series At Canaweld, we strive to empower welders with the latest advancements in welding technology. The M250 Series is a testament to our commitment to excellence, providing welders with a powerful, versatile, and comfortable welding solution. Experience the future of welding with the Canaweld M250 Series - Your Ultimate Welding Companion!

Buy

In Stock

Manufacturer

New

ASME

Land Freight

Elevate Your Operational Efficiency with Compressor Leasing from CWB National Leasing Enhancing Your Business with Flexible and Economical Equipment Solutions In various industries, from construction and manufacturing to automotive repair, compressors play a critical role in powering tools and processes. Leasing compressors through Canadian Western Bank (CWB) National Leasing offers a practical and financially astute solution for businesses seeking to enhance their operational capabilities. Here’s how leasing compressors can benefit your business: 1. Quick Equipment Access CWB National Leasing recognizes the importance of having the right equipment at the right time. They offer a fast and efficient leasing process, with decisions typically made within 48 hours of application submission. This quick turnaround ensures that your compressors can be delivered and operational promptly, minimizing any interruptions to your business operations. 2. Increased Financial Leverage Leasing compressors with CWB National Leasing empowers your business with enhanced buying power. Opting for periodic payments instead of a large initial purchase helps to free up cash for other essential business investments. Moreover, the option to add extra features or accessories to your compressors for a small payment increase allows for customization to meet your specific operational needs. 3. Effective Cash Flow Management With smaller lease payments over the term, your compressors begin to contribute to your business’s revenue while still being paid off. This balanced approach helps in maintaining a healthy expense-to-revenue ratio, which is key for the growth and sustainability of your business. 4. Flexible Payment Structures CWB National Leasing offers a range of payment plans, including seasonal, semi-annual, or annual options, to align with your business’s financial cycle. This flexibility is particularly beneficial for businesses with variable or seasonal revenue patterns, ensuring that payments are manageable and fit your financial situation. 5. Potential Tax Advantages Leasing compressors can offer tax benefits, such as the ability to expense lease payments rather than capitalizing the cost of the equipment. Consulting with a tax advisor is advisable to explore how leasing can enhance your business’s tax position. Conclusion Choosing to lease compressors through CWB National Leasing is a strategic decision that provides your business with essential equipment while maintaining financial flexibility. It ensures access to state-of-the-art compressors, vital for efficient and effective operations, without the financial strain of a large upfront investment. This leasing approach enables enhanced operational capabilities, business expansion, and increased profitability, helping your business to thrive in a competitive marketplace.

Service

In Stock

Service

New

ISO

Digital

Software Development

Embrace Sustainability: Redefine Energy Management with ELEKS As the world shifts towards renewable energy sources, forward-thinking organizations are taking the lead in creating a more sustainable future. With ELEKS' software development expertise, you can navigate the path to sustainable energy solutions and significantly reduce your direct carbon footprint. Our innovative solutions empower you to embrace environmentally-friendly practices, encourage climate change awareness, and streamline energy management practices—all while cutting costs and enhancing your operational efficiency. Pioneering Sustainability with ELEKS Energy Software Development: Unlock the potential of an advanced energy management software solution that transforms your business power system into a beacon of sustainability, productivity, accessibility, and safety. Investment in Sustainable Energy Solutions: Our software development expertise guides you in making strategic investments in sustainable energy solutions, such as electric vehicles powered by emerging technologies. Join the ranks of industry leaders committed to building a greener future. Environmentally Friendly Energy Consumption: Cultivate a culture of environmentally-friendly energy consumption within your organization. Our solutions empower you to lead by example and inspire others to adopt sustainable practices. Climate Change Awareness: By embracing sustainable energy solutions, you're not only reducing your carbon footprint but also raising climate change awareness within your industry. Be a catalyst for positive change and inspire others to follow suit. Reduced Costs and Streamlined Practices: Sustainability doesn't just benefit the environment—it also benefits your bottom line. Our solutions help you streamline energy management practices, optimize processes, and reduce operational costs. ELEKS: Your Partner in Sustainability Decades of Expertise: With 30 years of experience in custom software development, ELEKS is a trusted partner in helping energy producers, distributors, and organizations optimize energy efficiency and drive sustainability. Cutting-Edge Solutions: Our software team is at the forefront of innovation, utilizing Cloud, IoT, blockchain, drones, and other cutting-edge technologies to design bespoke data-driven software solutions and energy management systems. Addressing Industry Challenges: We understand the unique challenges faced by the energy and utility industry. Our solutions are tailored to address the specific needs of various energy sources, facilities, and businesses. Embrace the Green Revolution with ELEKS ELEKS' software development expertise is your gateway to a sustainable future. By adopting eco-friendly energy solutions, you're not only reducing your carbon footprint but also contributing to a more sustainable world. Lead the way in your industry, inspire change, and partner with ELEKS to redefine energy management for a brighter future.

Service

Made to Order

Service

New

ISO

Digital

Software Development

Unlock Rapid Development Excellence with ELEKS Smart Team In the fast-paced world of software development, staying ahead demands innovation, efficiency, and expertise. ELEKS Smart Team offers you the key to rapidly scale your development capabilities and drive your project towards success. With a track record of over 700 end-to-end projects and a roster of more than 2000 skilled experts, we empower you to achieve unparalleled development excellence. ELEKS Smart Team: Your Partner in Progress Accelerate Time-to-Market: Your success hinges on speed. ELEKS Smart Team accelerates your product's journey to the market by offering best-fit resources, establishing an efficient Software Development Lifecycle (SDLC), crafting a comprehensive Quality Assurance strategy, and providing expert project management. Our efficiency-boosting scope decomposition reduces your time-to-market, ensuring you seize opportunities faster. Focus on Core Business: In the realm of development, every moment counts. Regardless of your project's SDLC stage, we seamlessly take on your requirements, handling even the most intricate software development needs. By entrusting us with these tasks, you gain the invaluable gift of time, enabling you to focus on developing your core business and nurturing your unique strengths. Empower Your Existing Team: Success thrives on collaboration. ELEKS Smart Team adopts your culture seamlessly, facilitating the uptake of process and behavioral changes within your internal teams. We assist in enhancing team competencies, sharing our expert knowledge in emerging technologies and process frameworks. Empowerment is at the heart of our approach. How ELEKS Smart Team Works: Optimized Team Allocation: We decode your requirements to curate an optimized team of experts from our pool of over 2000 software professionals. Every member is chosen to fit the unique task at hand, ensuring superior results. Expert Team Management: Our dedicated teams operate as distinct entities, aligned with your requirements and governed by our rigid standards. This setup frees you to concentrate on core business deliverables, knowing your project is in capable hands. Streamlined Project Kick-Off: From the very outset, we synchronize smart teams and establish effective communication channels. Our ELEKS Project Managers and Technical Leads ensure seamless coordination, setting the stage for success. Transparent Delivery Framework: Transparency fuels confidence. ELEKS Smart Team operates within a unique delivery framework that combines Agile methodologies, experience, and robust security standards. This approach guarantees consistent, predictable, and transparent results, providing full visibility at every step. ELEKS Smart Team: Your Partner for Rapid Progress With an impressive Net Promoter Score (NPS) of 69 and a roster of the top 1% of Ukrainian engineering talent, ELEKS Smart Team is your catalyst for unparalleled development excellence. Let us pave the way for your success, turning challenges into opportunities and aspirations into achievements. Experience the power of rapid development with ELEKS Smart Team, where innovation meets expertise.

Service

In Stock

Service

New

ISO

Digital

Conventional Pumpjack

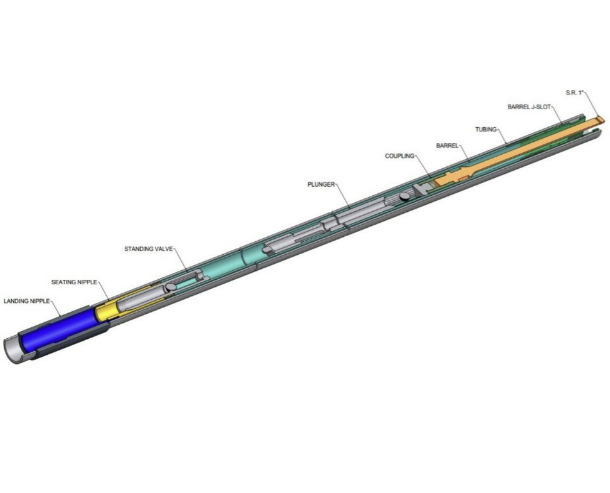

The Conventional Crank Balanced Pumping Unit, widely known and accepted, is the old reliable “Work Horse” of the oil patch. This is the most universally adaptable unit. These units are simple to operate and require minimum maintenance. Unit Size C-320D-256-144 A 120.00 B 180.00 C 260.00 E 215.25 F 353.75 H 398.00 I 32.75 J 110.00 L 72.50 M 76.00 N 21.13 N1 16.13 R 136.88 T 34.00 U 98.63 V 52.00 W 43.00 X 112.50 AA 53.625 AB 93.00 UU 31.00 VV 48.25 In addition to being the world’s leading manufacturer and supplier of sucker rod pumping units, all brands – Lufkin, Churchill, American, LeGrand, Bethlehem, National, etc. – are supported.

Buy

Currently in Use

Product

Used

API

Land Freight

Xanthum Gum

Introducing Xantham Gum from Cleanstream – the versatile solution for your drilling and completion needs. As a leader in providing innovative and environmentally responsible solutions for the oil and gas industry, Cleanstream is proud to offer this unique polymer for rheology modification, hole cleaning, and solids suspension. What sets Xantham Gum apart is its ability to provide excellent friction reduction – a feature that is unmatched by most other polymers in oilfield drilling and completion applications. Additionally, it can be used in most types of water-based fluids, making it an incredibly versatile product for your operations. Our in-house laboratory facilities allow us to determine the right approach to solve your specific problem. And at Cleanstream, we are committed to developing eco-friendly solutions for as many applications as possible. Whether you need Xantham Gum for a specific project or require our personnel and equipment for complete execution, we have you covered. Click on the datasheet for more information or contact us to learn how Xantham Gum can benefit your operations. Trust Cleanstream for innovative and sustainable solutions for your oil and gas needs.

Buy

In Stock

Manufacturer

New

ISO

Land Freight

Software Development

Unlocking Technological Opportunities with ELEKS' Technical Feasibility Study In today's fast-paced business landscape, staying ahead means embracing innovation. But before you invest your resources, it's essential to understand the potential of emerging technologies. At ELEKS, we're your partners in exploring the latest tech trends and uncovering their possibilities for your business. Our Technical Feasibility Study, backed by our award-winning R&D team, empowers you to make informed decisions that drive innovation and success. Empowering Innovation: Explore Emerging Technologies: Navigating the vast landscape of emerging technologies can be overwhelming. We're here to guide you. Our experts delve into the realms of blockchain, IoT, AR/VR, RPA, and AI to evaluate their potential impact within your unique business environment. Solve Problems Innovatively: With reduced financial risks, you can adopt a more innovative problem-solving approach. Our seasoned engineers collaborate closely with your project team throughout the feasibility study, tackling even the most complex challenges head-on. Validate Ideas Before Investment: Mitigate risks by testing uncharted solutions to your most intricate business problems before making significant investments. Our Technical Feasibility Study minimizes technological uncertainties, giving you and your stakeholders the confidence to invest in solutions that truly work. Craft a Vision for the Future: ELEKS assists you in evaluating the alignment of emerging technologies with your current market situation and potential for investment. If a technology isn't immediately viable, we help you strategize for the right time, ensuring a solid use-case or resource-saving potential. Gain a Competitive Edge: Identify untapped market opportunities and develop solutions grounded in real-world demands using cutting-edge technology. Our expertise empowers you to create a unique selling proposition, elevating your existing products and introducing new high-tech solutions to gain a competitive advantage. Navigating the Path to Technological Success: Structured Feasibility Studies: 1. Initial Research: Our R&D team conducts exhaustive research to understand your business challenges, defining clear goals for your solution. We then assemble a team equipped to deliver on those goals. 2. Hypothesizing and Testing: With expert insights, we develop problem-solving hypotheses and rigorously test them to define the optimal technological approach. 3. Technology Selection: We identify software stacks and hardware components that align with your business requirements. Our deep knowledge allows us to assess the advantages and disadvantages of innovative technologies. 4. Deployment and Next Steps: Our experts guide you through deployment, ensuring smooth technology integration and uptake. Our Centers of Excellence provide dedicated support, including project management, BA, QA, and customer support, tailored to your feasibility study. ELEKS: Your Gateway to Technological Vision: With ELEKS' Technical Feasibility Study, you're not just investing; you're innovating with confidence. Our unwavering commitment to technology exploration and excellence positions us as your trusted partner in shaping a future defined by cutting-edge solutions. Step into the realm of innovation with ELEKS and witness the transformation of your ideas into tangible success. Embrace the future today – because your technological vision is worth it.

Service

Made to Order

Service

New

ISO

Digital

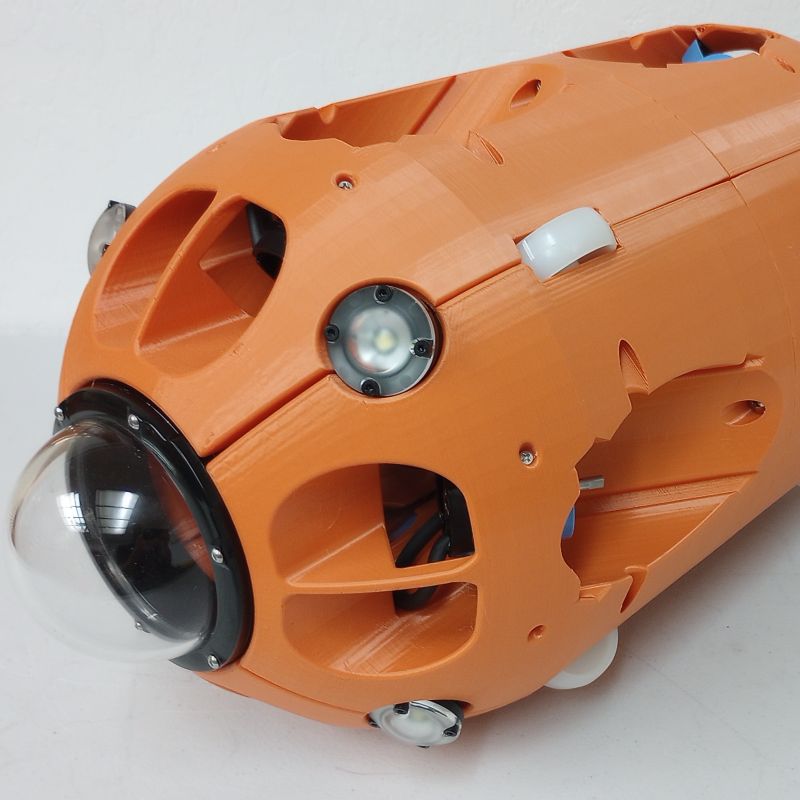

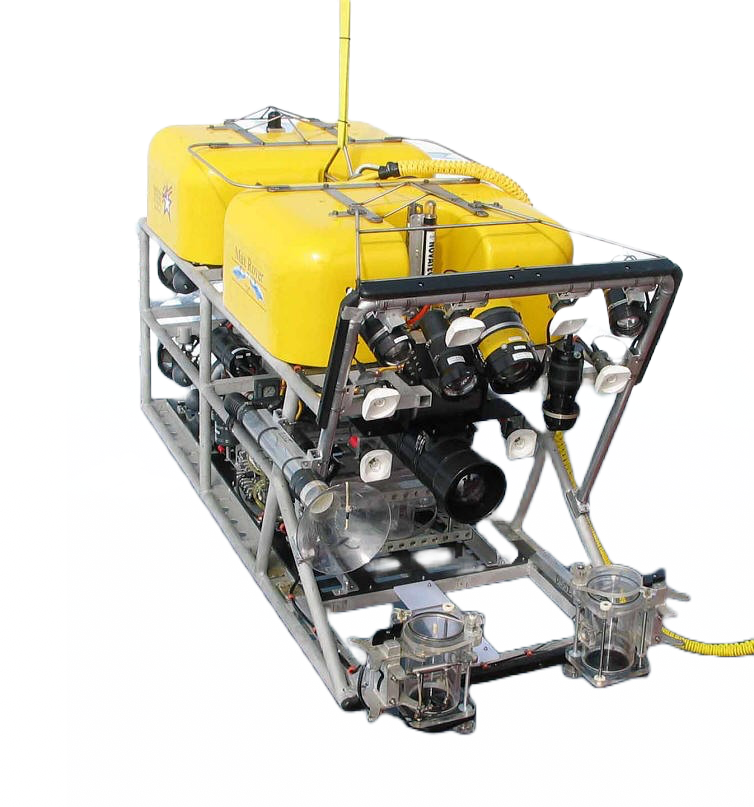

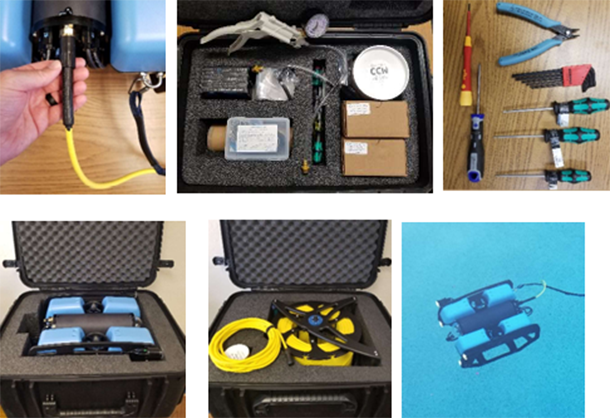

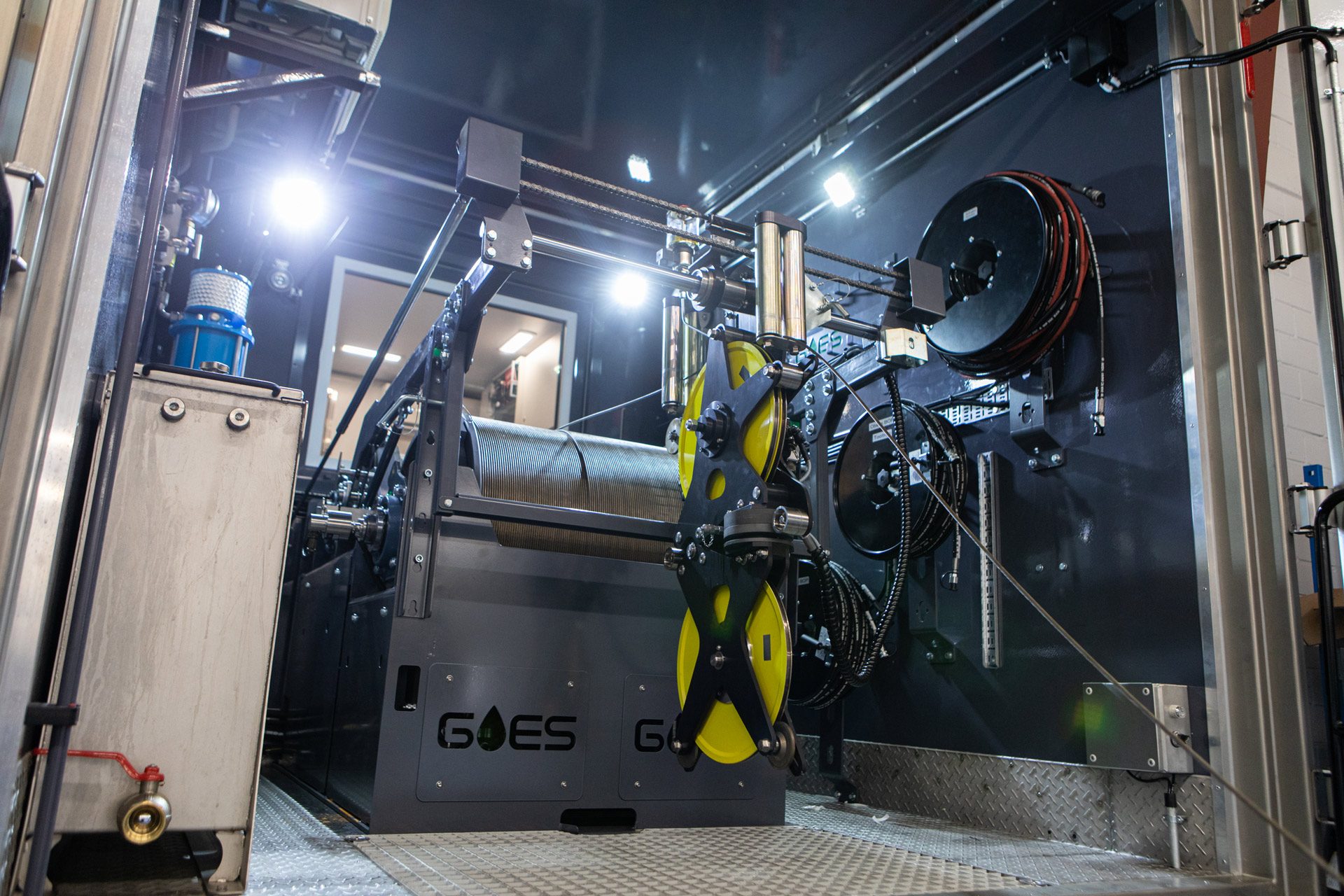

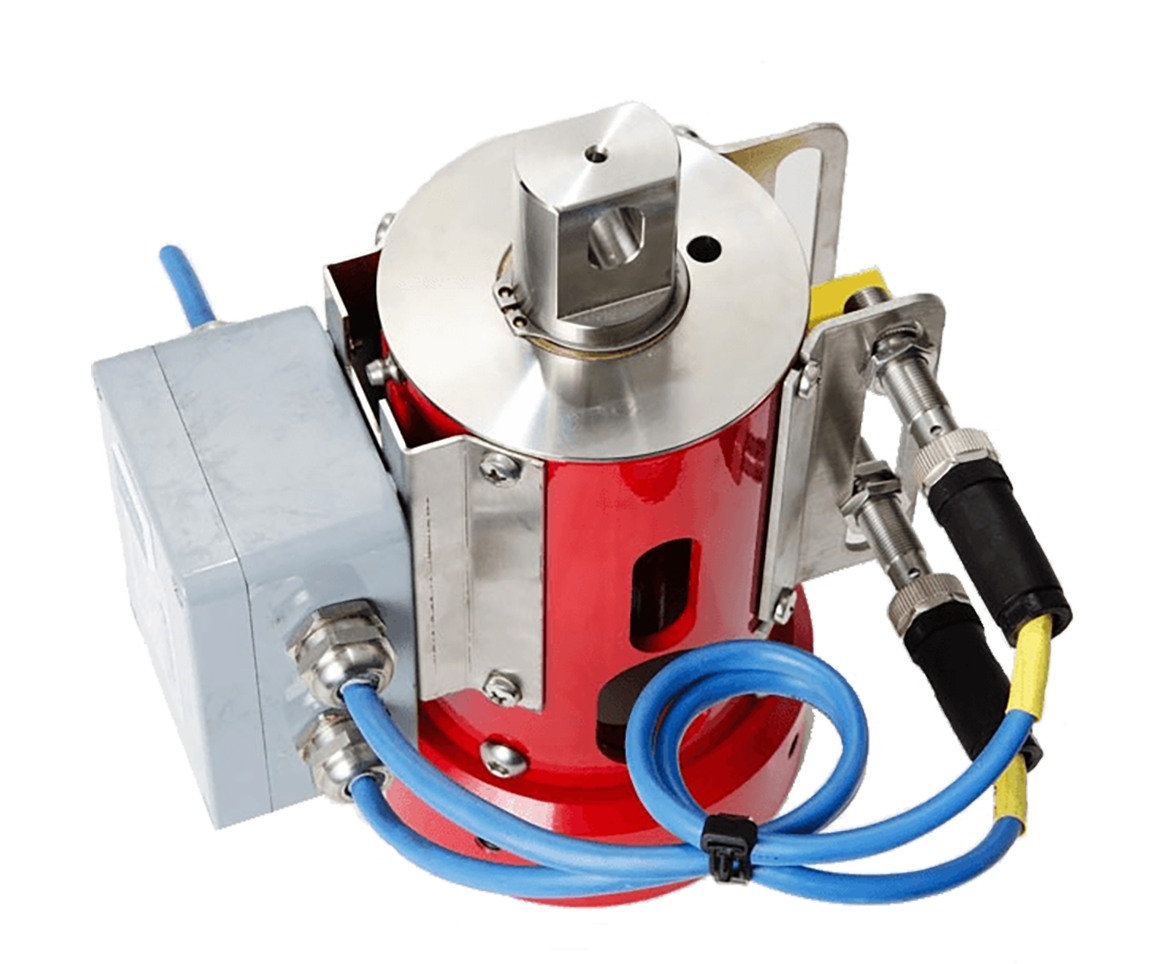

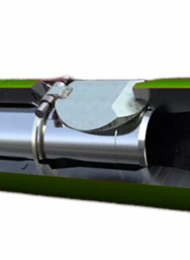

Pipe Inspection ROV

Introducing the NIU ROV: Your Ultimate Pipe Inspection Solution Poseidon Robotics is thrilled to unveil the latest addition to our fleet of advanced subsea robotics: The NIU ROV - The Pipe Inspection Remote Operated Vehicle. Engineered to excel in pipe and tunnel inspections, the NIU ROV sets new standards for versatility, precision, and efficiency in the subsea industry. Unleash the Power of NIU ROV The NIU ROV is purpose-built to navigate the intricate and challenging environments of pipes and tunnels. With its compact design, this remarkable ROV can effortlessly maneuver through a 12-inch diameter pipe, providing unparalleled access to previously hard-to-reach areas. From industrial pipelines to underwater tunnels, the NIU ROV is your go-to solution for comprehensive inspections. Unparalleled Performance The NIU ROV is equipped with state-of-the-art technology and robust features that ensure exceptional performance in every operation. Its advanced thrusters enable precise movement and control, allowing operators to conduct inspections with utmost accuracy. The powerful onboard lighting system ensures crystal-clear visibility even in the darkest and murkiest conditions. Efficiency Redefined At Poseidon Robotics, we understand the value of time and efficiency in subsea operations. The NIU ROV is designed to streamline your inspection processes, significantly reducing downtime and operational costs. Its ease of deployment and user-friendly interface enable quick setup and seamless integration into your inspection workflows. Tailored for Pipe and Tunnel Inspections Unlike generic ROVs, the NIU ROV is engineered specifically for the unique challenges of pipe and tunnel inspections. Its rugged construction and protective measures safeguard it from potential hazards encountered in these confined environments. With the NIU ROV, you can confidently conduct inspections with minimal risk and maximum efficiency. Cutting-Edge Technology The NIU ROV incorporates cutting-edge technology, including high-resolution cameras, to provide a comprehensive view of the inspection area. Its real-time data transmission capabilities allow operators to monitor and analyze data on the surface, making informed decisions on the spot. Unlock New Possibilities with NIU ROV From oil and gas pipelines to municipal infrastructure, the NIU ROV opens up a world of possibilities for inspecting critical subsea assets. Its adaptability and versatility make it an indispensable tool for various industries, including energy, construction, engineering, and more. Partner with Poseidon Robotics When you choose the NIU ROV from Poseidon Robotics, you not only invest in a top-of-the-line inspection solution but also gain access to our unmatched expertise and support. Our team of subsea specialists is ready to assist you every step of the way, ensuring that you harness the full potential of our advanced ROV technology. Embark on a New Era of Pipe Inspections Step into the future of subsea inspections with the NIU ROV - The Pipe Inspection Remote Operated Vehicle. Experience unparalleled performance, efficiency, and precision in your pipe and tunnel inspections. Contact Poseidon Robotics today to explore how the NIU ROV can revolutionize your subsea operations. Your success is our mission!

Buy

In Stock

Manufacturer

New

ASME

Air Freight

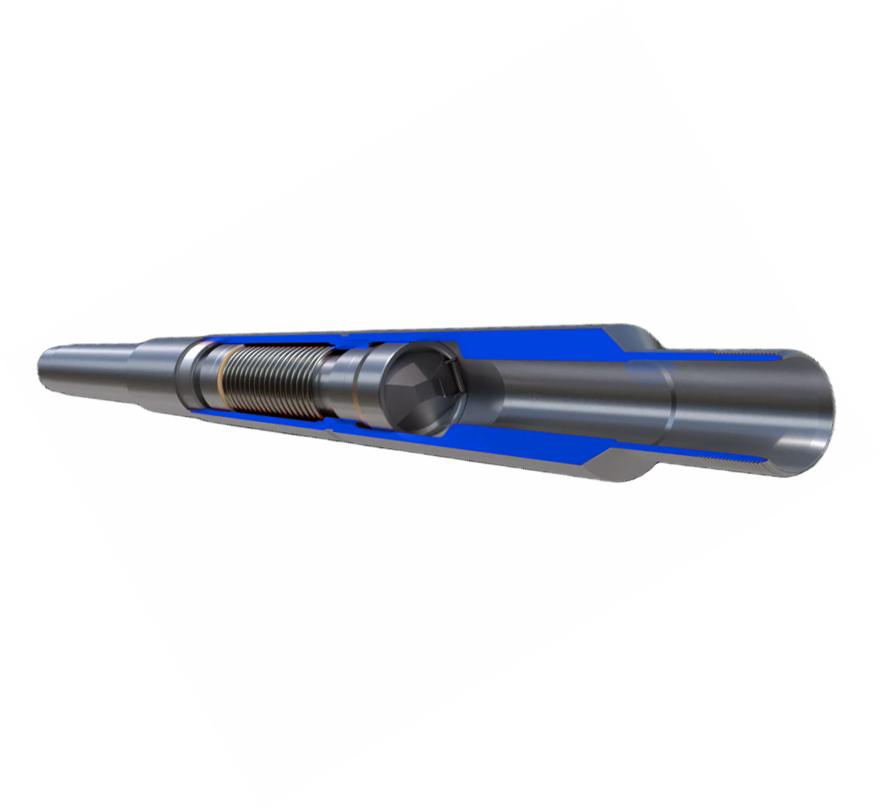

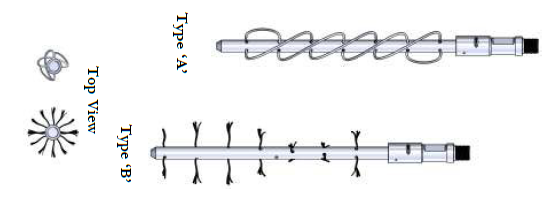

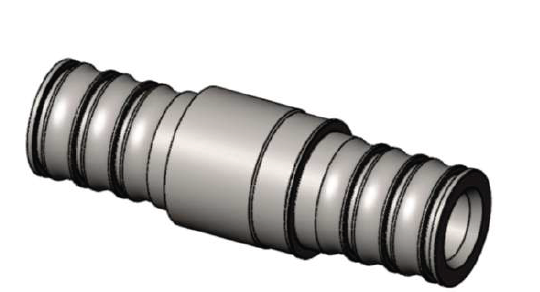

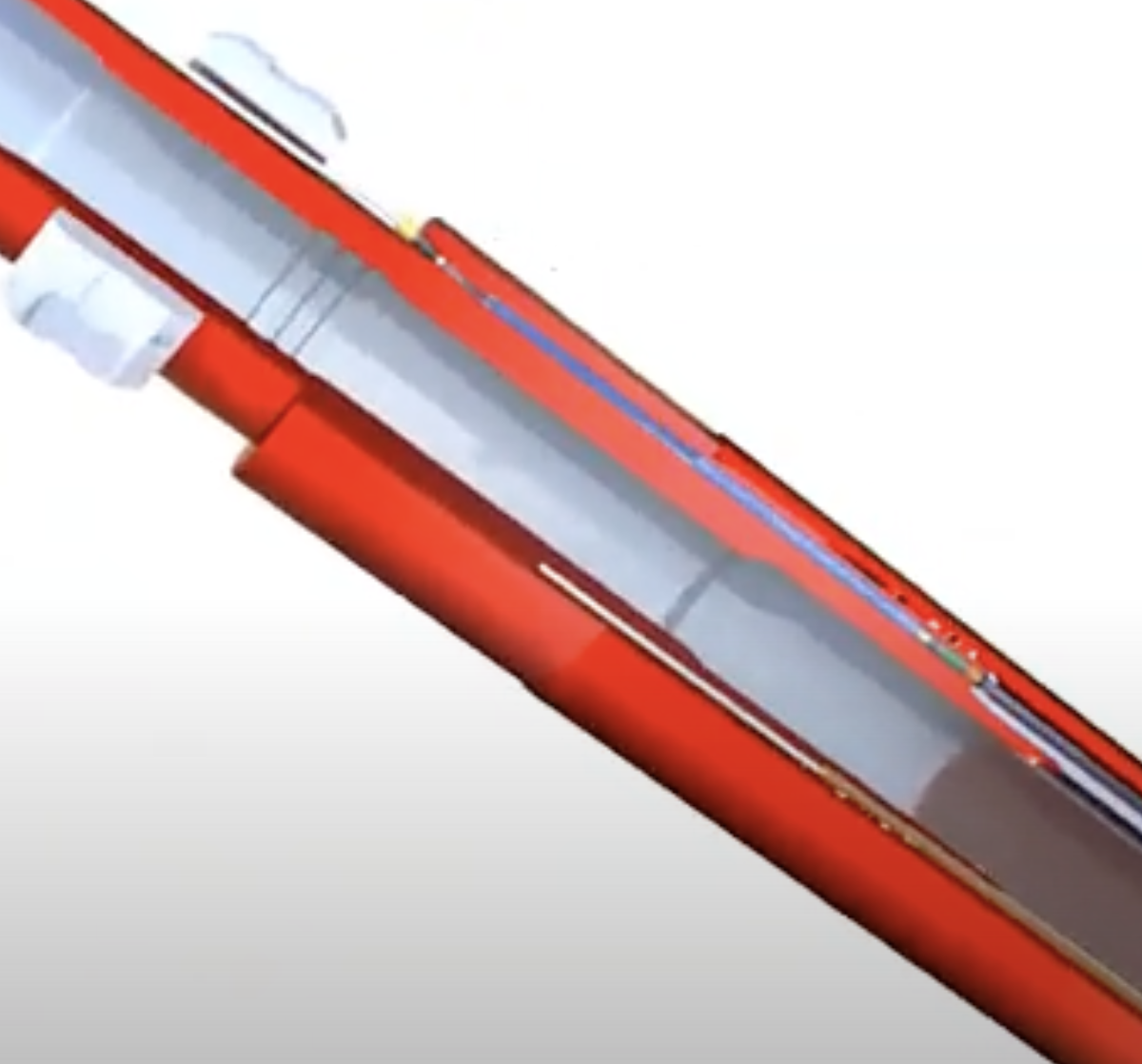

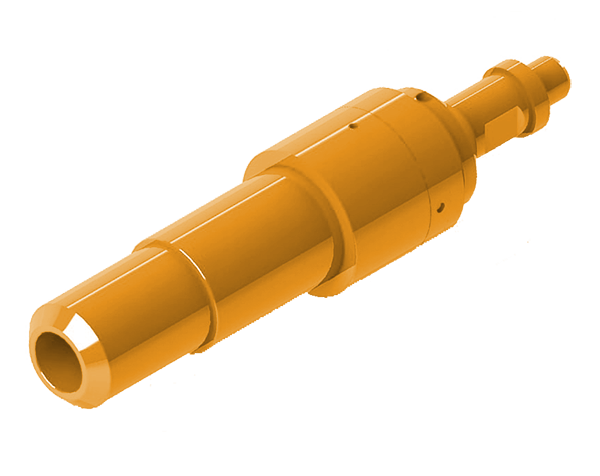

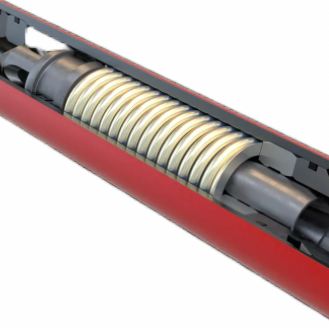

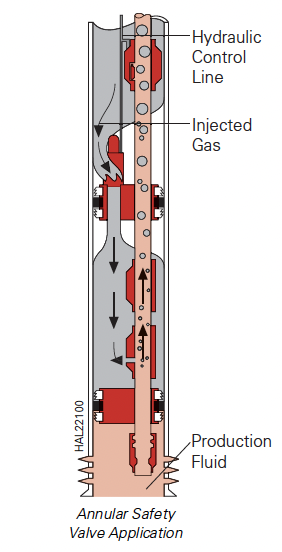

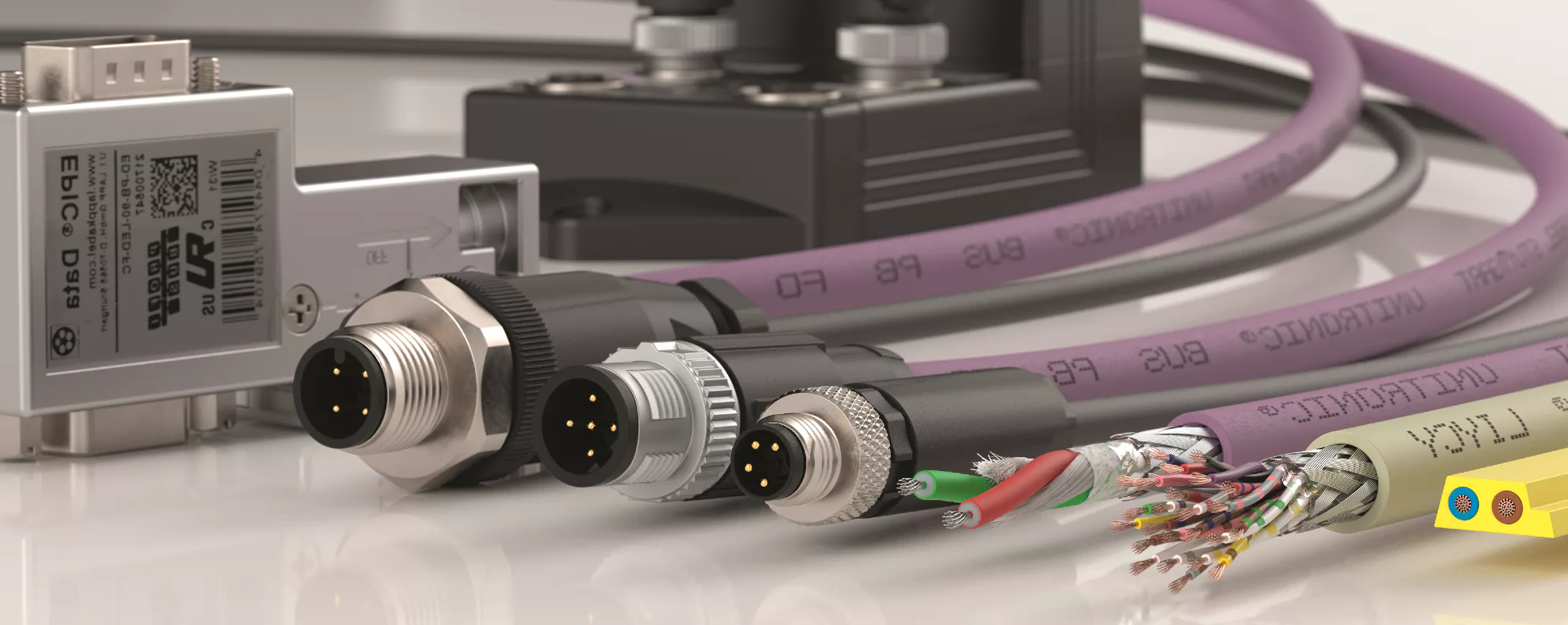

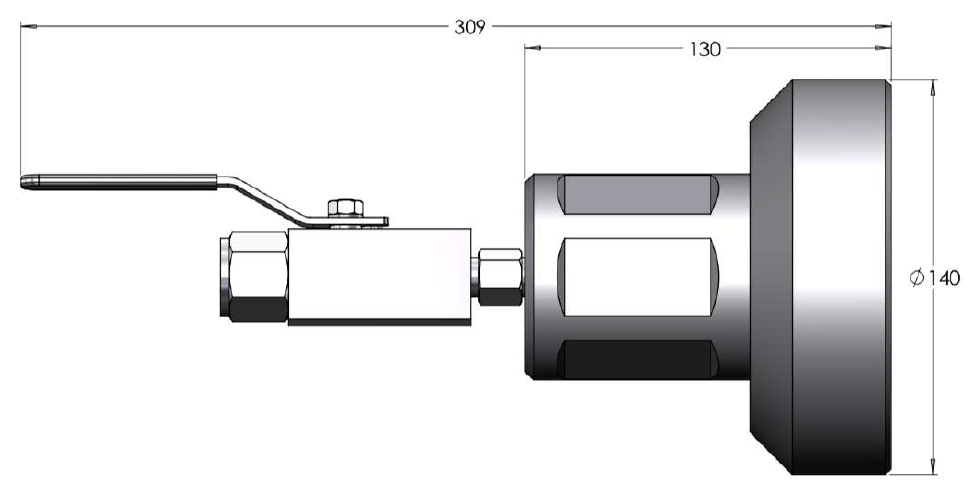

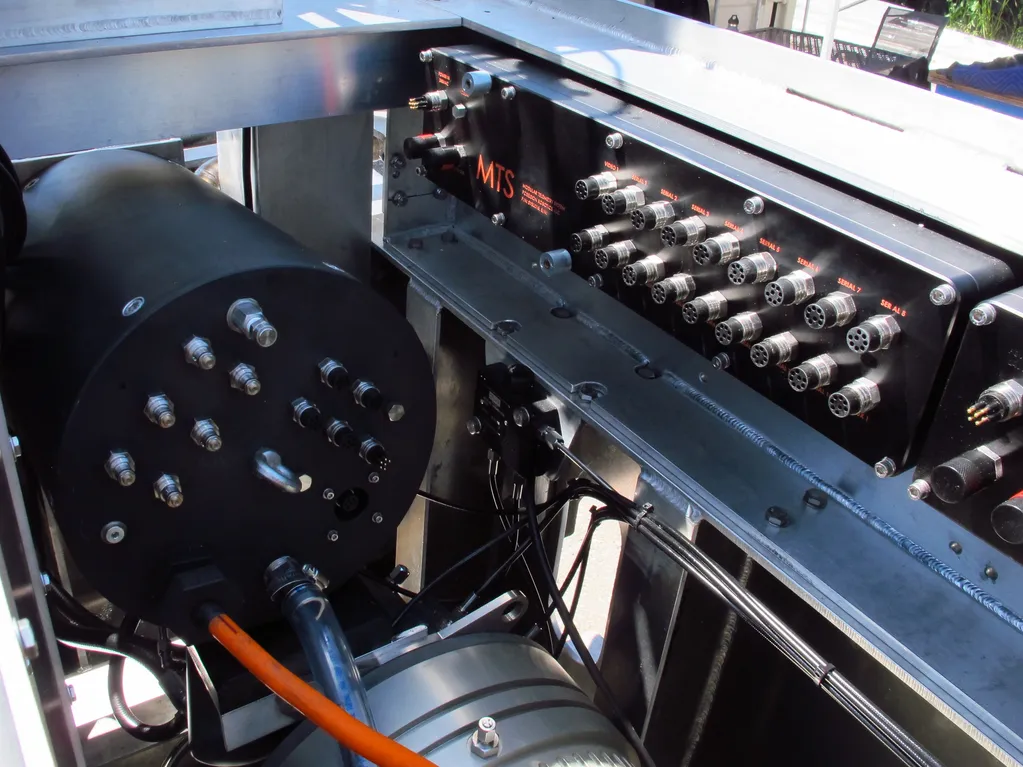

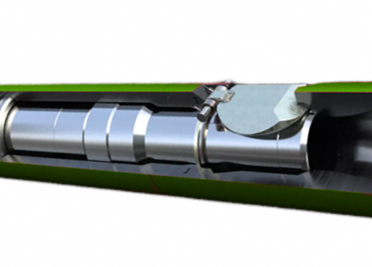

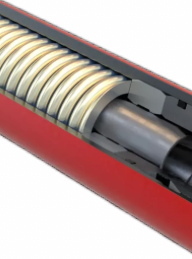

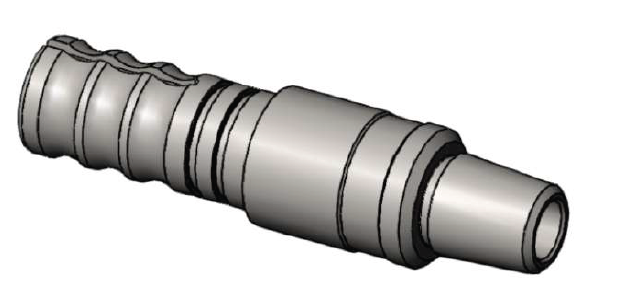

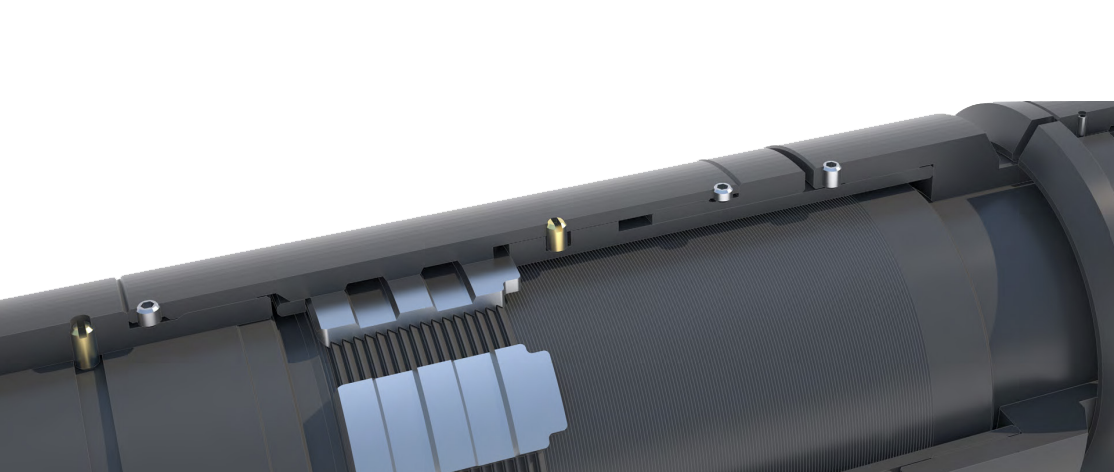

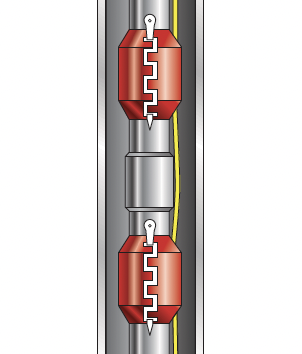

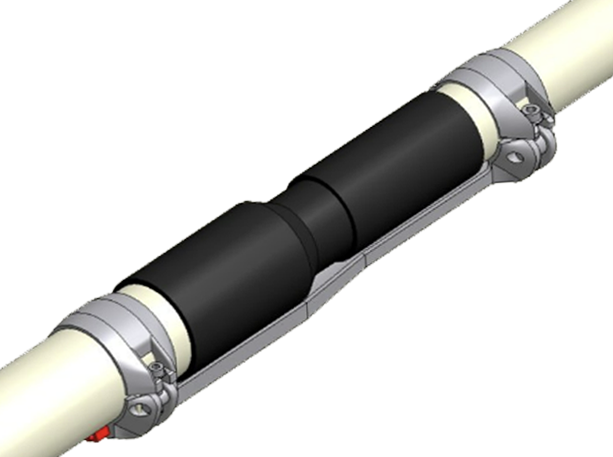

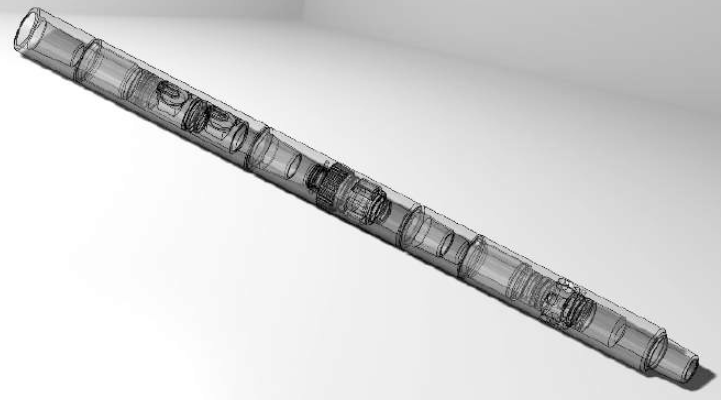

1/4 inch control line

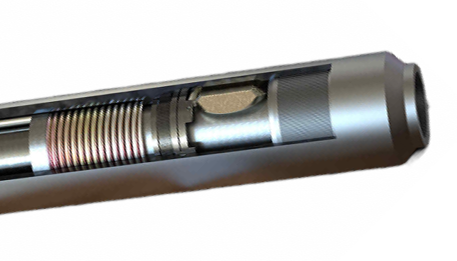

Control lines are assembled on reels filled with fluid and pressure tested. Reel spools are designed so pressure can be applied at any time during running to check control-line integrity. Hydraulic control lines are made from two different manufacturing processes that conform to ASTM specifications: (1) seamless and (2) welded and sunk. Seamless Tubing is fabricated from a solid rod. The process involves forcing a mandrel or punch through the solid rod to form a tube. The continuous lengths available from this process are limited. Welded and Sunk Tubing is fabricated from flat stock. The process involves rolling the stock into a cylinder and welding the seam. Once in tube form, it is drawn through a die to achieve the proper OD. This process is considerably less costly than the seamless method and yields lines available in continuous lengths with no butt-welded connections. Optional single and dual lines with protective encapsulation are available. The encapsulated material is suitable for use in most annular fluids. Encapsulation protects lines from damage during installation and simplifies the running process. The dual-encapsulated line can be used with “balanced” SCSSVs or injection wells where multiple lines are required. As an option, a protective cable between two control lines is available. Single-encapsulated lines have no cable; however, a protective cable on either side of the control line can be ordered. Installation Control lines are attached to subsurface controls with appropriate tube fitting and pressure tested before running into the wellbore. Line spools are hung in the derrick, and control line is paid out as tubing is run. Applications » For SCSSVs Features » Different lengths of control line in continuous coil » Stainless and alloy 825 materials offered » Control lines offered in various encapsulated options » All control lines conform to ASTM specifications » Lines available in other sizes on request *information sourced from manufacturer

Buy

In Stock

E&P

New

API

Sea Freight

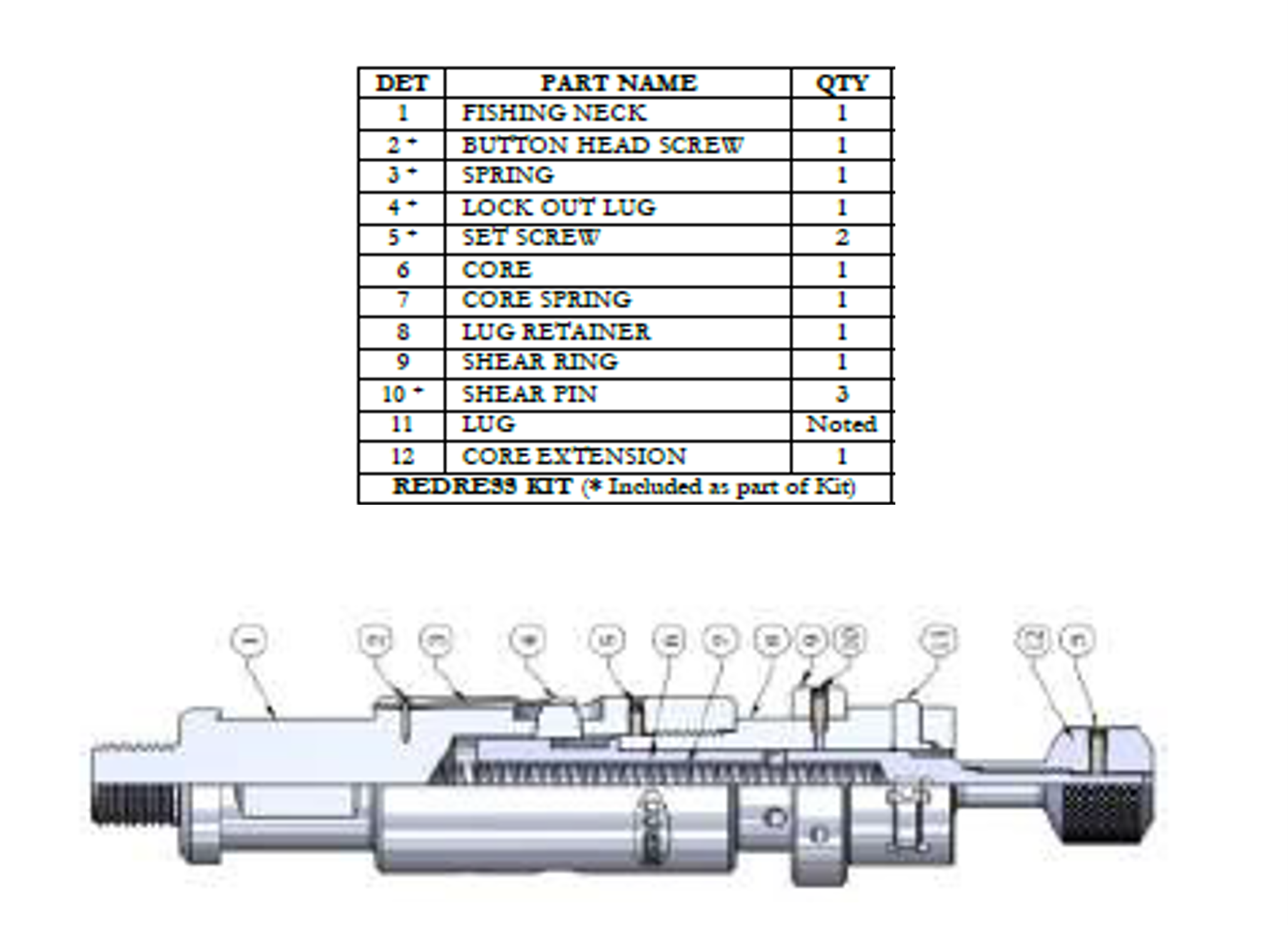

Downhole Tools

Unlocking Efficiency: HOCA Oil Tools' Lock Mandrels for Tubing In the demanding realm of oil and gas operations, ensuring the integrity and functionality of well components is paramount. HOCA Oil Tools, a pioneer in downhole slick line tools, introduces its cutting-edge Lock Mandrels for Tubing – an essential solution designed to enhance the performance and reliability of downhole activities. These tools are engineered for precision, delivering unmatched reliability and performance to meet the rigorous demands of modern well operations. HOCA's Lock Mandrels for Tubing: Precision-Engineered for Superior Performance Our Lock Mandrels for Tubing are designed to securely latch into the tubing string, providing a stable base for various downhole tools and devices. Tailored to accommodate different tubing sizes and pressures, they are essential for the effective management and control of wellbore fluids. Fabricated from high-quality materials and built to withstand the harshest downhole environments, HOCA's Lock Mandrels ensure operational success and longevity. Experience the HOCA Oil Tools Advantage Opting for HOCA Oil Tools’ Lock Mandrels for Tubing means choosing a partner committed to your operational success. Our dedication to quality and innovation ensures that our products not only meet but exceed the expectations set by the demanding oil and gas industry. Incorporating our Lock Mandrels into your tubing operations signifies a step towards enhanced efficiency, safety, and control. With HOCA Oil Tools, you gain more than just equipment; you gain a strategic advantage supported by our expertise and unwavering commitment to excellence. Choose HOCA Oil Tools for your downhole needs and join the ranks of satisfied clients who rely on our Lock Mandrels for Tubing to secure their operational success. Partner with us, and harness the power of precision-engineered solutions to elevate your downhole activities. With HOCA Oil Tools, empower your downhole operations with tools that redefine reliability, efficiency, and performance in the oil and gas industry.

Buy

In Stock

Product & Service

New

API

Air Freight

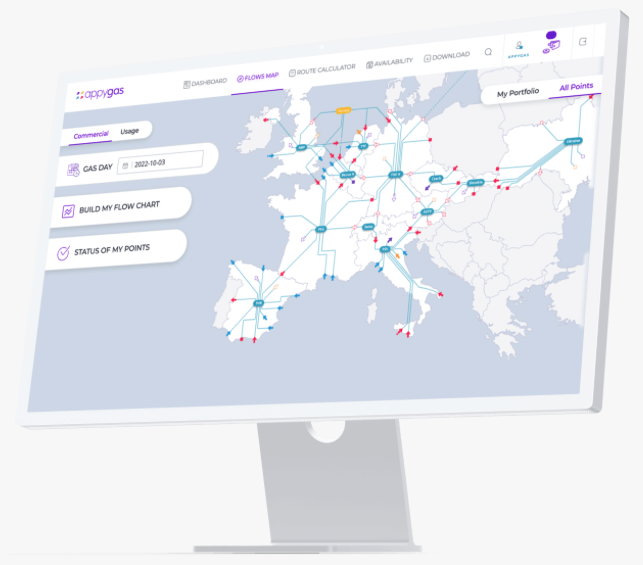

KEY360

KEY360 Inc offers a single integrated Business Management Platform comprising Business Intelligence, Project Management, Big Data & Analytics, ERP, Behaviour and Strategy Modification. - Over 140 Business and Project Management Systems on one platform available - Unique and extremely effective workflow engine - Remarkable “BIG DATA” and bulk transaction capability - Integrated Real Time reporting and dashboarding - Multi-company platform allows all project users to integrate seamlessly KEY Differentiators: - KEY360 Provides an exceptional opportunity for your organisation to attract new clients and build long terms relationships. - KEY360 is a Microsoft Gold Partner and Approved Microsoft Co-Sell Partner and can be purchased directly from the below online marketplaces: - Microsoft AppSource: KEY360 Capital Management Projects - Azure Marketplace: KEY360 Capital Management Projects - KEY360 is reputedly the most comprehensive and versatile Capital Project Management, Business Digitalization & Business Optimization solution available.

Service

In Stock

Service

New

ISO

Digital

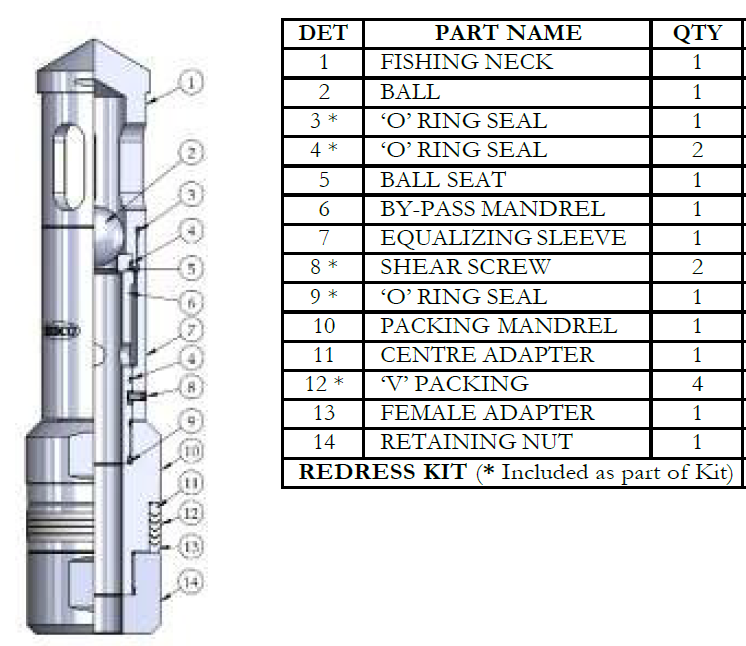

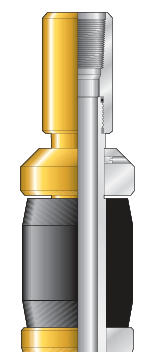

3.39 inch safety valve

The WI retrievable injection valve is a high-performance, high-flow rate injection valve. High throughput is achieved by a unique valve configuration that minimizes turbulent and potentially erosive flow. Operation is not dependent on a specific flow rate, pressure, or setting depth, thus negating the need for adjustment over time. The valve incorporates a metal-to-metal valve and seat energized by the combination of an integral spring and well pressure acting from below. The WI injection valve can be deployed on a wireline lock or through-tubing pack-off device, providing flexibility not available with alternative injection valve systems. As a result of the simple design with fewer parts, redress and repair costs are considerably lower than those for other injection valve systems. Applications The WI injection valve is primarily used in water injection applications as an alternative to conventional tubing or wireline-set safety valves. The valve is also commonly used as a retrofit solution in water injectors in which a tubing to annulus leak has occurred. The valve can be deployed below the leak point to eliminate uncontrolled annulus pressure increases when the injection stops. Features » Compatible with all known lock systems » Dedicated designs to suit Halliburton EB0 intervention packers » Enhanced internal flow profile » Simple design and construction » Flow-loop testing performed to establish pressure drop versus pump rate *information referenced from supplier catalog.

Buy

Made to Order

Product

New

API

Sea Freight

Personal FInancial Services