3-1/2" WR-SCSSSV FXE

WR-SCSSSV

Also known as:

WRSCSSSV, WRSCSSV, Wireline Retrievable Safety Valve

3-1/2" WR-SCSSSV FXE

WR-SCSSSV

Also known as:

WRSCSSSV, WRSCSSV, Wireline Retrievable Safety ValveBuy

Made to Order

Manufacturer

Price:

Request for QuoteShipping:

Air freightDelivery Time:

4 - 6 WeeksNote:

The 3-1/2" WR-SCSSSV delivers fail-safe well control with wireline retrievability and flapper-style shut-in protection.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

The 3-1/2" WR-SCSSSV FXE is installed in the upper section of the wellbore, these safety valves provide emergency shut-off of the production tubing when needed. The system is designed to automatically isolate the wellbore in case of any failure or damage to the surface production control equipment.

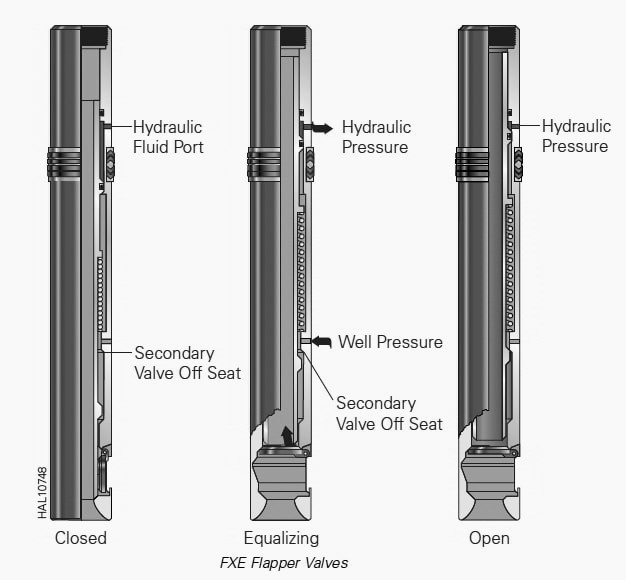

The valve is surface operated, wireline retrievable, self-equalizing, and features a flapper-type design. It is placed within compatible landing nipples as part of the safety system.

Technical Specifications

| Tubing Size | 3-1/2" (88.90 mm) |

| Landing Nipple Seal Bore | Options (2.562" / 2.750" / 2.813") |

| Working Pressure | 5000 PSI |

| Valve ID | Options (1.00" / 1.50") |

| Valve Type | Flapper Type |

| Control Type | Surface Controlled |

| Retrievability | Wireline Retrievable |

| Installation Location | Upper Wellbore |

| Material | Flapper made from solid bar stock |

| Equalizing | Self Equalizing |

Features and Benefits

- Self equalizing type.

- Working pressure up to 10,000 psi.

- Sealing and sealing surfaces are out of flow path, when valve is in the open position.

- Solid construction of flapper made from bar stock.

- Automatically isolates the wellbore if surface systems fail.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

Available sizes: 2 3/8”, 2 7/8”, 3 1/2”, 4”, 4 1/2”, 5”, 5 1/2'” and 7”

The 3-1/2" WR-SCSSSV FXE is a Ballycatter model safety valve specifically designed for installation in the upper wellbore to provide an emergency shut-off of the production flow path.

This valve plays a crucial role in well control by isolating the wellbore during emergency situations such as system failures or damage to surface production control facilities. Its fail-safe design ensures that the valve automatically closes to protect the wellbore and surface equipment whenever a fault occurs.

This safety valve is a flapper-type valve that is both surface controlled and wireline retrievable, allowing operators to easily deploy, operate, and retrieve the valve without extensive well intervention. The valve is installed within a corresponding model Landing Nipple, ensuring precise fit and reliable operation within the tubing string.

The design incorporates a self-equalizing mechanism that balances pressure differentials across the valve, which helps maintain consistent performance even under varying downhole pressures. This self-equalizing feature reduces the risk of valve malfunction due to unexpected pressure changes.

When the valve is in the open position, the sealing surfaces are positioned outside the flow path, ensuring that the fluid can pass freely without obstruction or erosion on the sealing components. This arrangement optimizes flow efficiency and helps extend the valve’s operational life. The flapper itself is made from solid bar stock, providing a strong and durable barrier that can withstand the harsh conditions found in high-pressure well environments.

The valve is rated for working pressures up to 10,000 psi, allowing it to operate reliably under high-pressure well conditions. The 3-1/2" WR-SCSSSV FXE is designed to ensure wellbore isolation in emergency situations, providing a critical safety function in the well control system.

Engineering Data