Don't have an account? Join for free

-

-

All Categories

-

Construction

-

Marine

-

Subsea

-

Process Equipment

- View All Process Equipment

- Compressor

- Controls

- Diesel Generator

- Fire Suppression

- Gas Turbine

- Motors

- Pressure Vessels

- Separators

- Heater Treater

- Heat Exchanger

- Coalescers

- Tanks

- Pumps

- Water Treatment

- Piping

- Structural

- Flanges

- Electrical

- Valves

- Instrumentation

- Bearings

- Measurement

- Meters

- Thermometers

-

Chemicals

- Communications

- IT

- Scaffolding

- HVAC

- Accommodations

- Light Masts

- Flare Stacks

- Pumpjacks

- Chokes

- Pigs

- Gas Detection

- Potable Water

- Fire Fighting

-

Renewable

- Hydraulics

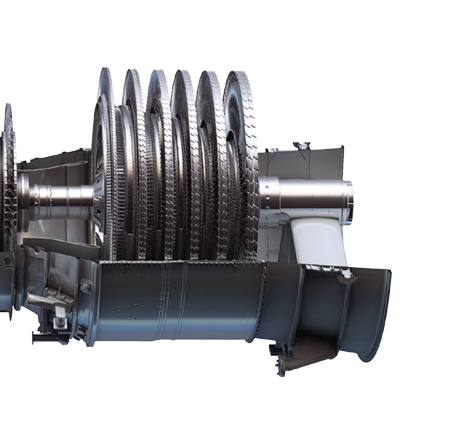

- Steam Turbine

- LNG

- CNG

- RNG

- Biogas

- Hydrogen

- Nitrogen

- CCUS

- Piping

- Pipelines

- Personnel

- Gas Plant

- Oil Battery

- Alternative Energy

-

Transport

-

Workover

- View All Workover

-

Logging

-

Slickline

- Slickline Surface Equipment

- Slickline Basic Tools

- Slickline Standard Tools

- Slickline Baker Tools

- Slickline Remedial Equipment

- Slickline Special Tools

- Slickline Pulling Tools

- Slickline Camco Tools

- Slickline Petroline Tools

- Slickline Halliburton Tools

- Slickline Fishing Tools

- Swab Cups

- Lead Impression Block

- Slickline Swage Tool

- Slickline BOP

- Slickline Pressure Control Equipment

- Wireline Insert Valve

- Inflatable Packers

- Cement Retainers

- Slickline Surface Equipment

- Electric Line

-

Coiled Tubing

- Snubbing Unit

- Service Rig

- Flushby Unit

- Well Testing

-

Pumping

-

Perforating

-

Casing

-

Work Clothes

-

Tools

-

Waste Management

-

Industrial Cleaning

-

Completions

- View All Completions

- Packer Fluid

- Tubing Plugs

- Crossovers

- Nipple Profiles

- Sliding Side Doors

- Sliding Sleeve

- Side Pocket Mandrel

- Downhole Camera

- Fishing Tools

- X-mas Trees

- Wellheads

- Pup Joints

- Downhole Gauges

- Safety Valves

- SCSSV

- Artificial Lift

- Electric Submersible Pumps

- Gas Lift Valves

- Rod Pumps

- Beam Pumps

- Progressive Cavity Pumps

- Plunger Lift

- Tubing

- Packers

- Control Line

- Cross Coupling Protectors

- Slotted Liners

- Gravel Pack

- Perf Guns

- Sand Screens

- Multi Lateral Junctions

- Methanol

- Chemical Injection

- Wellhead Control Unit

- Air Compressors

- Pressure Gauges

- Hydraulic Control Unit

- Emergency Shutdowns

- Fire and Gas Detection

- Pressure Recorders

- Back Pressure Valves

- Tubing Hanger

-

Drilling

- View All Drilling

- Riser

- Blowout Preventer

- Accumulator

- Koomey Unit

- Rams

- Blind Rams

- Pipe Rams

- Shear Rams

- Variable Rams

- Annular

- TIW Valve

- Lubricator

- Top Drive

- Kelly Bushing

- Kelly Hose

- Slips

- Offices

- Piperack

- Drawworks

- Tongs

- Coring

-

Bits

- Mud Motors

- Iron Roughneck

- Monkeyboard

- Skidding System

- Under Reamer

- Lost Circulation Material

- LCM

- Landing Joints

- Drill Collars

-

Mud Mixer

- Casing Centralizers

- Pipe Dope

- Thread Protectors

- Hoses

- Chicksan

- Choke Manifold

- Heave Compensator

-

Open Hole Logging

- Cased Hole Logging

- Cuttings Handling

- Drilling Mud

- Elevators

-

Mining

-

All Categories

- Industry Directory

- Onshore

- Offshore