HDI 3300 Temperature Gauge System

Temperature Monitoring

Also known as:

Electronic Temperature Gauge, Ring Temperature Gauge

HDI 3300 Temperature Gauge System

Temperature Monitoring

Also known as:

Electronic Temperature Gauge, Ring Temperature GaugeBuy

In Stock

Manufacturer

Price:

Request for QuoteShipping:

Air freightDelivery Time:

3 WeeksNote:

The HDI 3300 Temperature Gauge System is a battery-powered electronic gauge used to monitor fluid temperatures in applications such as nitrogen pumping, mud drilling, well control manifolds, and flare stacks.Sign in

Welcome back

Sign up

Sign-up and make easy contact all providers in the industry.

Let's create your free account

Executive Summary

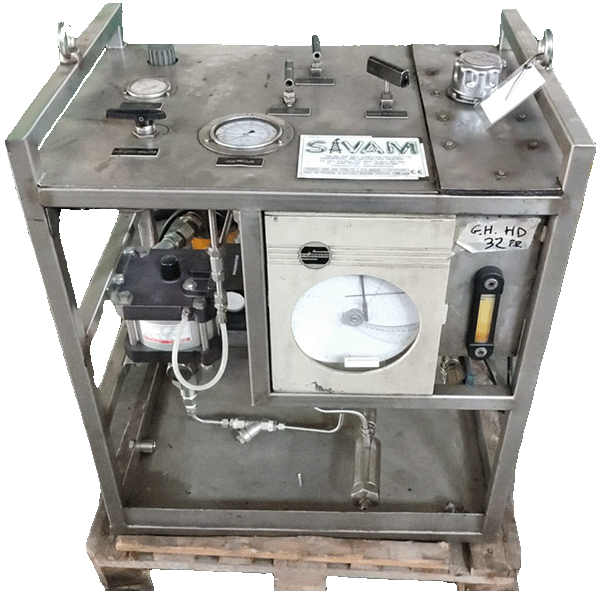

The HDI 3300 Temperature Gauge System is a solid-state electronic solution used to monitor fluid temperature in demanding oil and gas environments. It is commonly installed on high-pressure nitrogen units, geothermal wells, mud-based drilling systems, and flare stacks, where consistent and accurate temperature data is required for safe operations.

Built for both land and offshore applications, the system provides real-time temperature readings using a digital display connected to a remote sensor. The system helps operators make informed decisions by delivering reliable temperature monitoring without relying on moving parts or fluids. It is suited for hazardous areas and integrates easily into existing monitoring setups.

Technical Specifications

| Operating Temperature | -40°C to 70°C |

| Accuracy | ±0.5% of full scale |

| Resolution | 0.1°C or 0.1°F |

| Output Options | 4-20mA or 0-1 VDC |

| Display Type | LCD with 5-digit numeric and 101-segment bar graph |

| Sensor Type | Solid-state RTD housed in stainless steel |

| Enclosure Dimensions | 7¾" diameter x 4" deep |

| Weight | 5 lbs |

| Viewing Angle | 50 degrees |

| Mounting Options | 2” Male NPT, 2” 1502, 2” 2202, or flanged connections |

Features and Benefits

- Accuracy of 0.5% full scale.

- Provides accurate and continuous temperature monitoring.

- Intrinsically safe design allows use in hazardous environments.

- Sensor housed in stainless steel, compatible with multiple mounting options.

- Simple calibration interface.

Print or Share

Do you need information for the team or a client? Download these page to add your dossier.

Send an email with the link to this page. It's a great way to share information.

Detailed Description

The HDI 3300 Temperature Gauge System is an intrinsically safe, battery-powered electronic temperature measurement device commonly used in oil and gas operations requiring precise temperature monitoring. Typical applications include high-pressure nitrogen pumping, geothermal and mud-based drilling, well control manifolds, flare stacks, and bulk liquid storage.

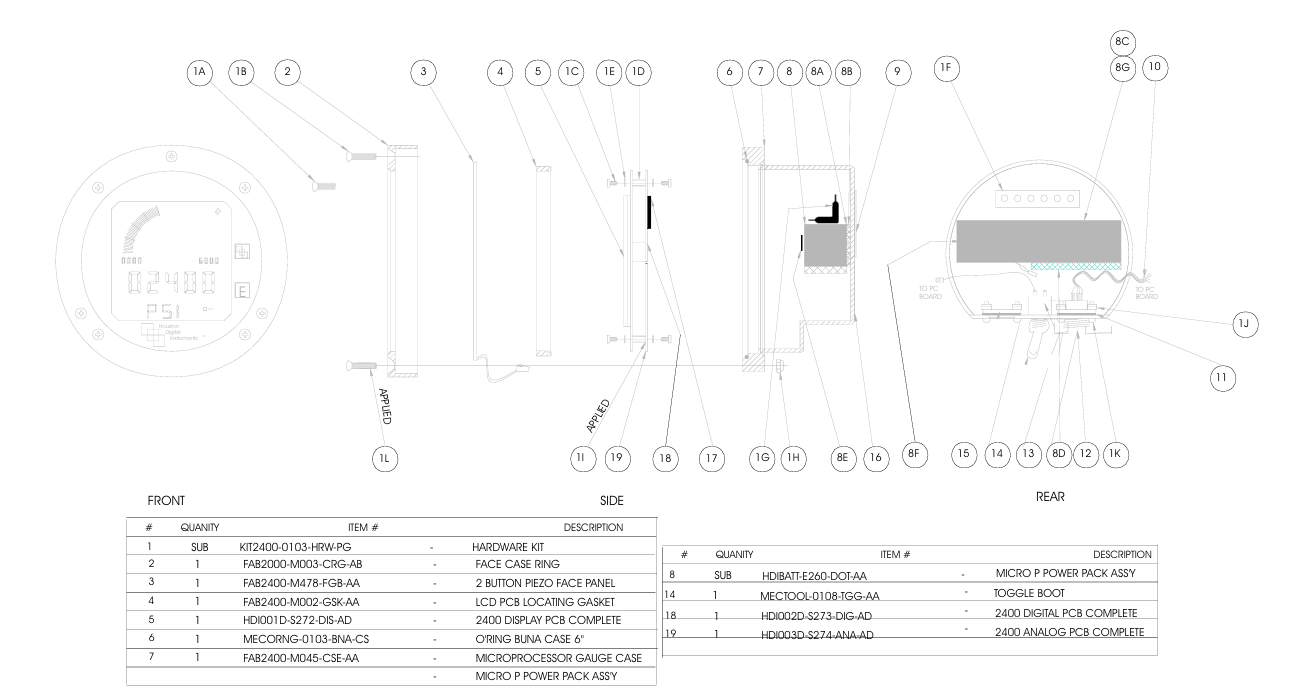

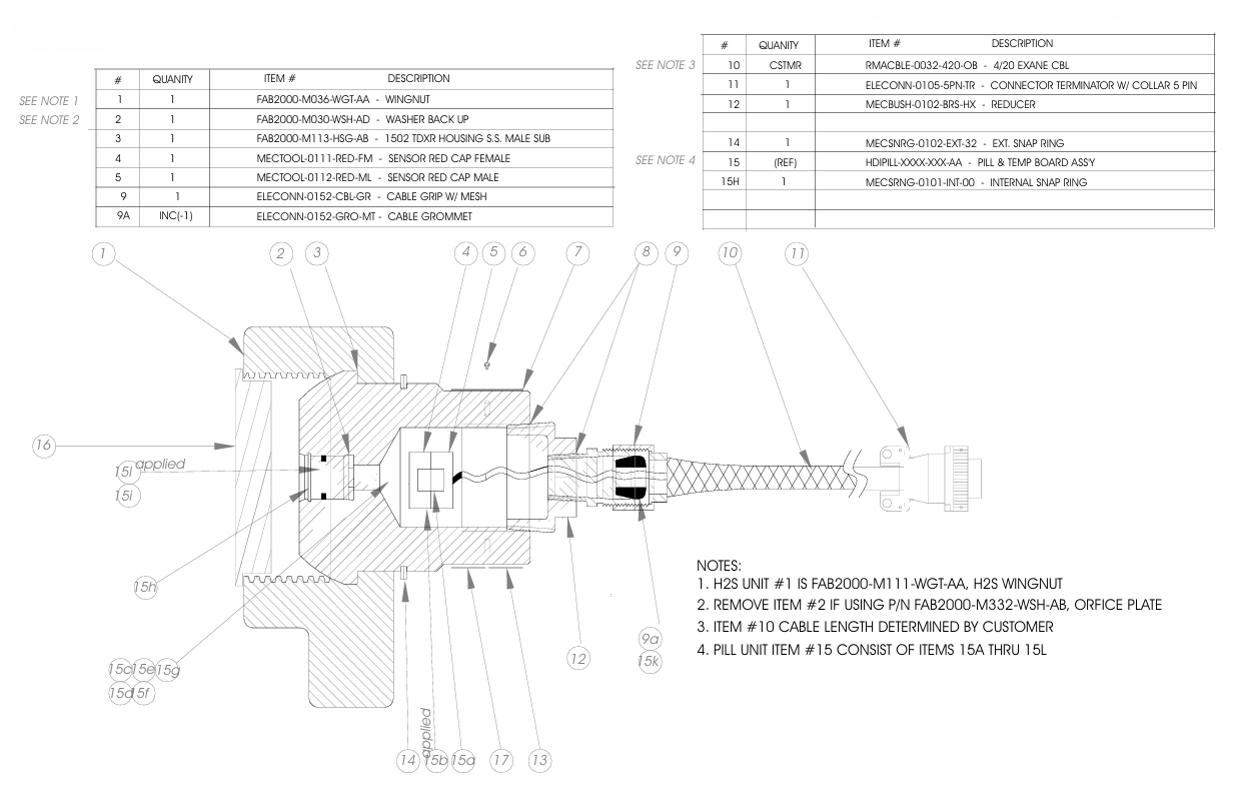

The system consists of a digital gauge display, sensor assembly, and interconnecting cable. The sensor, usually a Resistance Temperature Detector (RTD), is housed in a durable stainless steel case with various mounting options like 2-inch Male NPT, hammer unions, or flanges, allowing flexible installation near the temperature source.

The display features an LCD with numeric and analog bar graph outputs, providing temperature readings with 0.1-degree resolution and ±0.5% full-scale accuracy over a range of -50 to 150°C (-50 to 300°F). Users can switch between Celsius and Fahrenheit. It includes 4-20mA and 0-1 VDC output options for integration with remote monitoring, data logging, or control systems, and supports external power inputs.

Designed for ease of maintenance, the system is field-repairable with a replaceable battery pack. The sensor and display are factory-matched and calibrated, requiring recalibration if components are replaced. The gauge fits standard 6-inch panel cutouts and supports multiple mounting patterns. Cable lengths are customizable up to 200 feet or more.

The system operates reliably in temperatures from -40°C to +70°C and is certified for hazardous environments, with a rugged stainless steel sensor housing to withstand harsh field conditions.

The 3300 is well-suited for environments requiring precise, continuous temperature monitoring, including high-pressure drilling, well control, and fluid storage applications. Its intrinsically safe design provides dependable operation in hazardous locations without compromising safety. The solid-state electronics and durable construction reduce maintenance and downtime, while versatile mounting options allow placement close to the measurement point for accurate readings. Featuring clear numeric and bar graph displays along with remote output capabilities, the system supports timely decision-making and integrates easily with larger monitoring setups, enhancing process control and operational safety in demanding conditions.

Engineering Data